Variable area capacitive-type bimodal optimized tuning-fork-type micromechanical gyroscope

A technology of mechanical gyroscope and variable area, which is applied in the direction of speed measurement by gyroscope effect, gyroscope/steering sensing equipment, measuring device, etc. It can solve the problems of difficult increase of frequency difference, non-linear displacement and capacitance conversion, and decrease of gyroscope sensitivity. , to achieve the effect of reducing quadrature coupling error, good decoupling performance, and solving small range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] In order to further illustrate the technical means and effects taken by the present invention to achieve the expected purpose, so that the advantages and characteristics of the present invention can be more easily understood by those skilled in the art, the specific implementation methods, structural features and other aspects of the present invention will be described in conjunction with the accompanying drawings and examples. The efficacy is described in detail below.

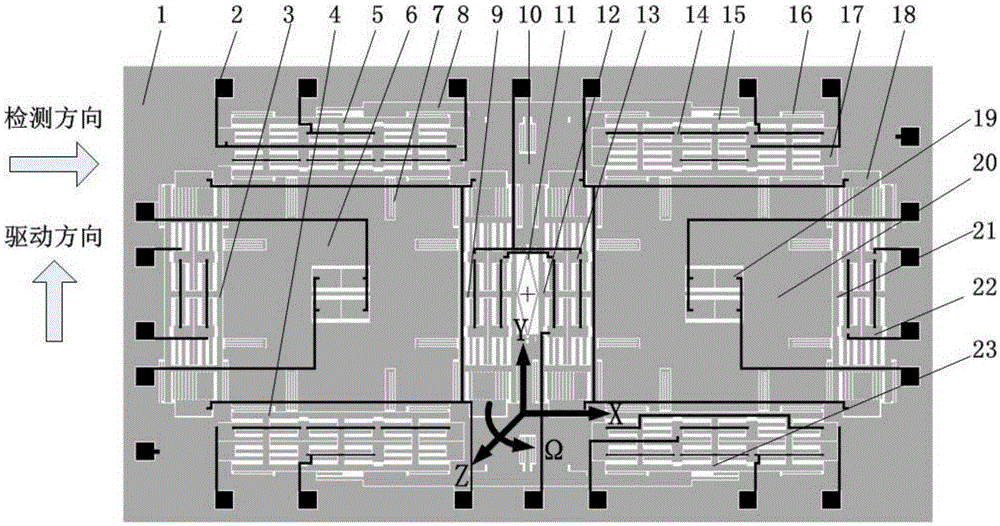

[0015] Such as figure 1 As shown, a variable-area capacitive dual-mode optimized tuning-fork micromechanical gyroscope disclosed in this embodiment includes a glass substrate 1 and a metal electrode 2; it also includes a MEMS structure, wherein a silicon chip is bonded on the glass substrate 1, Perform photolithography and deep etching on the silicon wafer on the glass substrate 1 to form anchor points 10, perform photolithography on the glass substrate 1, and sputter metal, form metal electrodes 2 by ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com