Multi-roll multi-chamber winding coating device

A technology of a coating device and a coating chamber, which is applied in sputtering coating, vacuum evaporation coating, ion implantation coating and other directions, can solve the problems of inability to obtain high-quality coating, difficulty in obtaining high-quality coating, and prolonged coating cycle, etc. , to achieve the effect of repeatability and stability, shortening the vacuuming time and saving space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

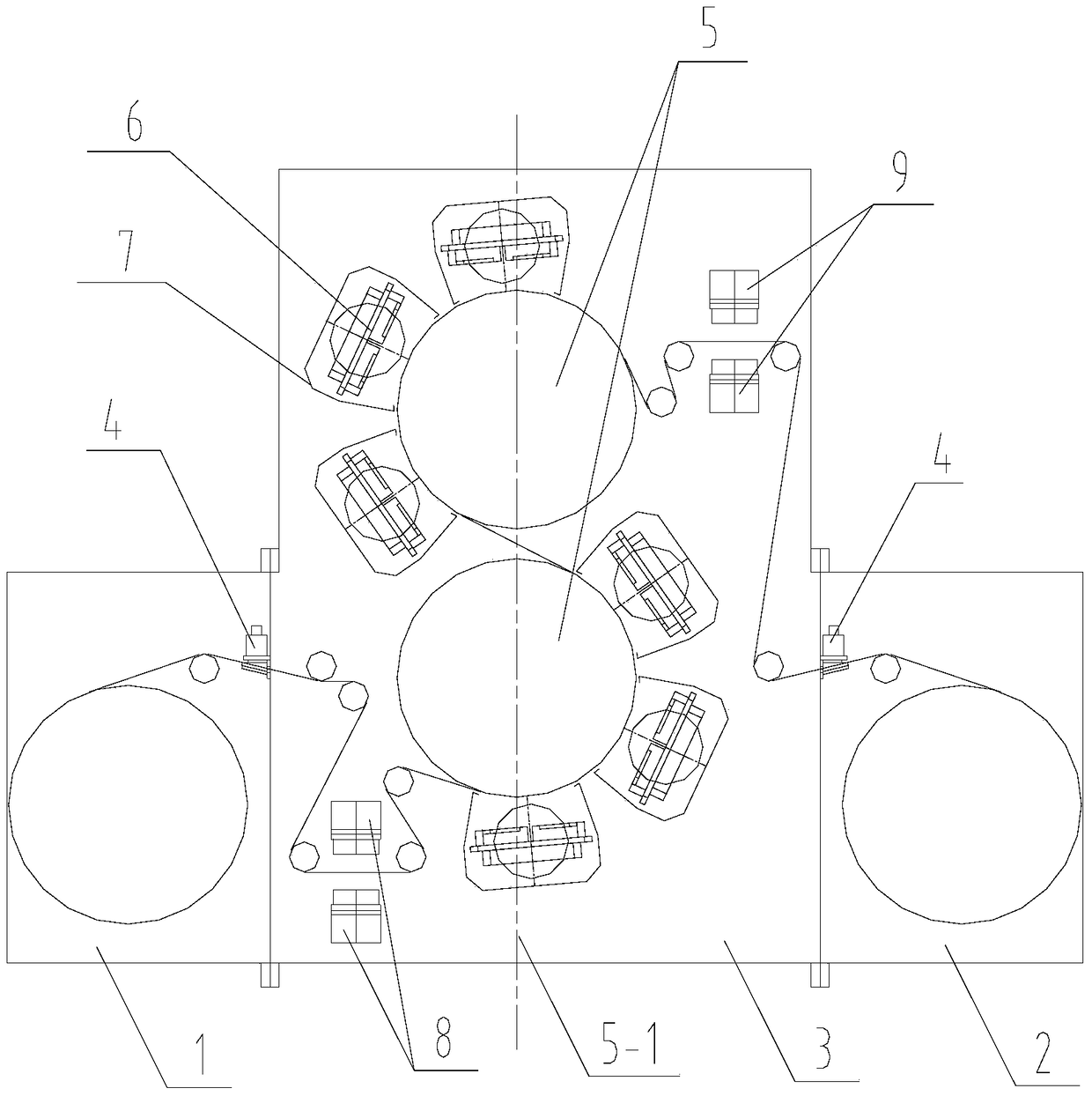

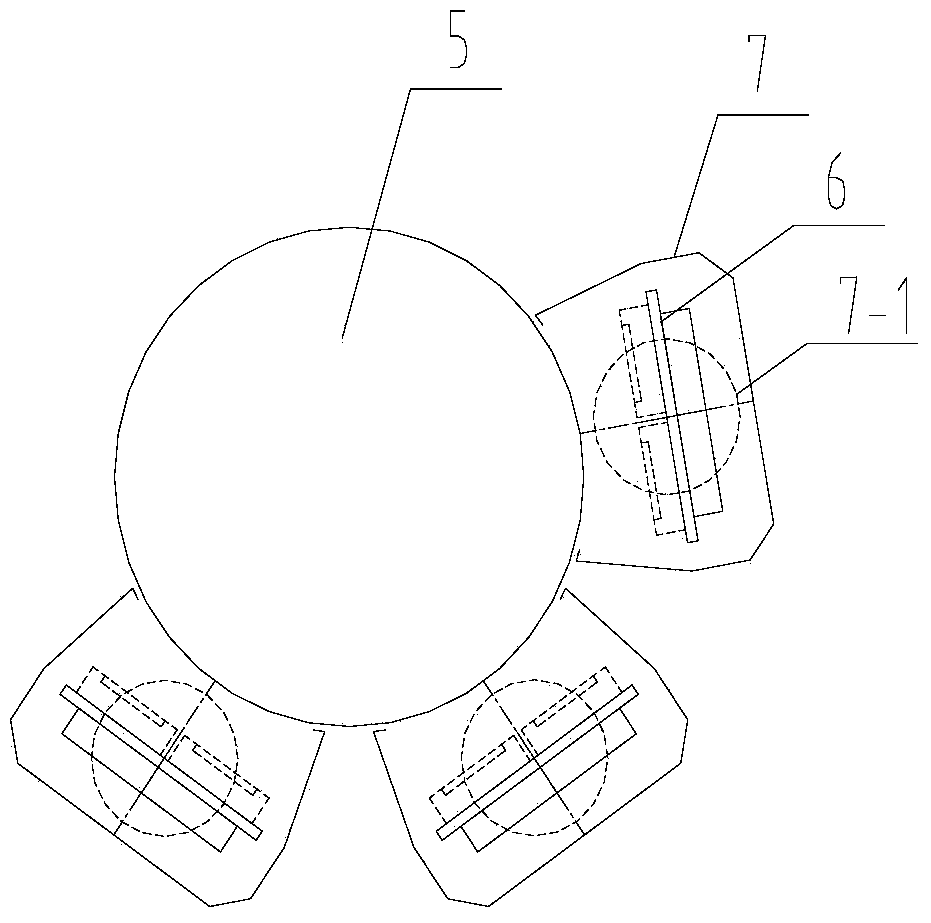

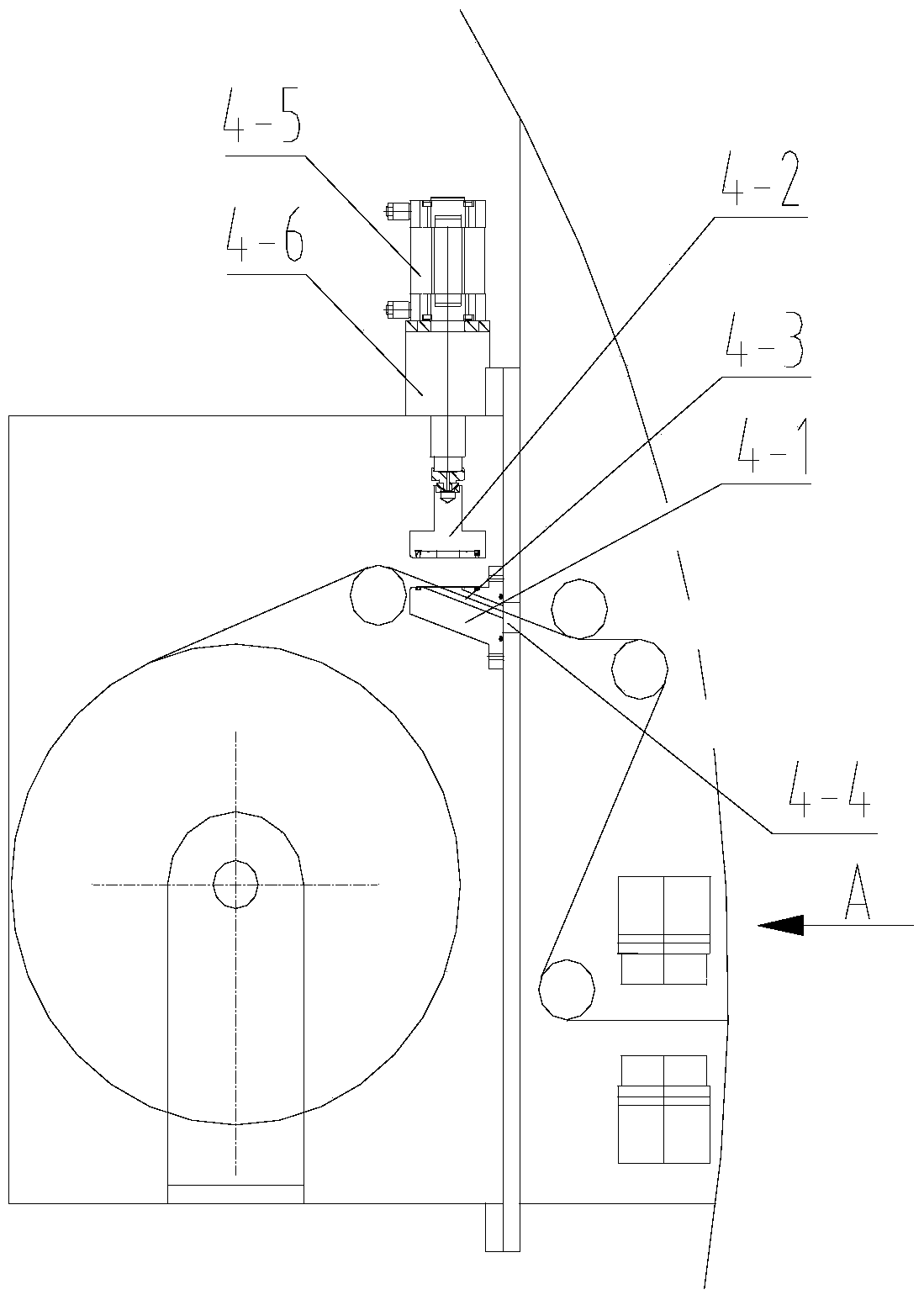

[0035] In this embodiment, a multi-roller multi-chamber winding coating device, such as figure 1As shown, it includes a plurality of independent vacuum chambers. The plurality of vacuum chambers include an unwinding chamber 1, a winding chamber 2 and a coating chamber 3. The unwinding chamber and the winding chamber are respectively arranged on both sides of the coating chamber. Any two A vacuum lock 4 is arranged between two adjacent vacuum chambers; two water-cooled drums 5 distributed up and down are arranged in the coating chamber, and at least two sputtering targets 6 are distributed on one side of each water-cooled drum, each sputtering target A target cover 7 is arranged on the outer periphery, and a gap for the winding substrate to pass is provided between the bottom of the target cover and the surface of the water-cooled drum, and each target cover is respectively connected with a vacuum unit, and an independent sputtering chamber is formed inside each target cover. W...

Embodiment 2

[0043] In this embodiment, a multi-roller multi-chamber winding coating device has a structure such as Figure 5 Shown, compared with embodiment 1, its difference is: there are two coating chambers, respectively the first coating chamber and the second coating chamber; the two water-cooled drums in the first coating chamber are the first upper water-cooled drum and The first lower water-cooled drum, three sputtering targets are distributed on the left side of the first upper water-cooled drum, and three sputtering targets are distributed on the right side of the first lower water-cooled drum; the two water-cooled drums in the second coating chamber are the second upper water-cooled Drum and the second lower water-cooled drum, three sputtering targets are distributed on the right side of the second upper water-cooled drum, and three sputtering targets are distributed on the left side of the second lower water-cooled drum.

[0044] When the multi-roller and multi-chamber winding...

Embodiment 3

[0046] In this embodiment, a multi-roller multi-chamber winding coating device has a structure such as Figure 6 Shown, compared with embodiment 1, its difference is: there are two coating chambers, respectively the first coating chamber and the second coating chamber; the two water-cooled drums in the first coating chamber are the first upper water-cooled drum and The first lower water-cooled drum, two sputtering targets are distributed on the left side of the first upper water-cooled drum, and two sputtering targets are distributed on the right side of the first lower water-cooled drum; the two water-cooled drums in the second coating chamber are the second An upper water cooling drum and a second lower water cooling drum, two sputtering targets are distributed on the right side of the second upper water cooling drum, and two sputtering targets are distributed on the left side of the second lower water cooling drum.

[0047] When the multi-roller and multi-chamber winding co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com