Anti-corrosion construction method for irregular steel structural part

A technology of steel structure parts and construction methods, applied in hot-dip plating process, metal material coating process, coating, etc., can solve the problems affecting the mechanical properties of platform steel structure materials, affecting the safety of platform use, and having no power system, etc. Achieve the effect of reducing the risk of cracking, avoiding excessive thickness of the zinc layer, and reducing the degree of oxidation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

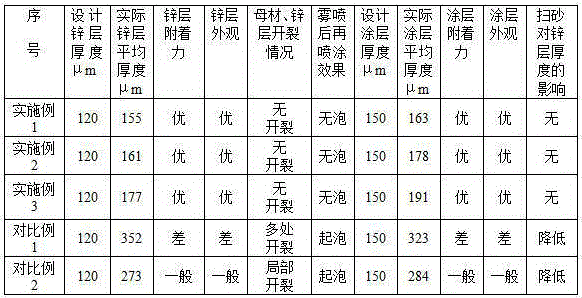

Embodiment 1

[0017] Anti-corrosion construction method for unconventional steel structure parts (5.8 tons, Q460 material), including the following steps:

[0018] (1) Chamfering treatment: Grinding and chamfering all the sharp edges and R holes of the steel structure, the radius of the chamfering is controlled at 2mm, so as to enhance the adhesion between the coating and the corners of the base metal;

[0019] (2) Shot blasting: Steel structural parts after chamfering are shot blasted with steel shot abrasives with an average particle size of 0.3 mm to remove scale, rust and other pollutants, and obtain an average roughness of 25 μm to reduce Residual stress in the production of steel structural parts, reducing pickling time and obtaining higher adhesion of zinc layer;

[0020] (3) Hot-dip galvanizing: The steel structure after shot blasting is pickled first and then dipped into the zinc pool for galvanizing. The pickling time is 45 minutes, and the volume of the zinc pool is 143m 3 , The...

Embodiment 2

[0025] The anti-corrosion construction method of unconventional steel structure parts (6.3 tons, Q460 material), including the following steps:

[0026] (1) Chamfering treatment: Grinding and chamfering all the sharp edges and R holes of the steel structure, the radius of the chamfering is controlled at 2.5mm to enhance the adhesion between the coating and the corners of the base metal;

[0027] (2) Shot blasting: Steel structural parts after chamfering are shot blasted with steel shot abrasives with an average particle size of 0.45 mm to remove scale, rust and other pollutants, and obtain an average roughness of 32 μm to reduce Residual stress in the production of steel structural parts, reducing pickling time and obtaining higher adhesion of zinc layer;

[0028] (3) Hot-dip galvanizing: The steel structure after shot blasting is pickled first and then dipped into the zinc pool for galvanizing. The pickling time is 60 minutes, and the volume of the zinc pool is 158m 3 , The ...

Embodiment 3

[0033] Anti-corrosion construction method for unconventional steel structure parts (6 tons, Q460 material), including the following steps:

[0034] (1) Chamfering treatment: Grinding and chamfering all the sharp edges and R holes of the steel structure, the radius of the chamfering is controlled at 3mm, so as to enhance the adhesion between the coating and the corners of the base metal;

[0035] (2) Shot blasting: Steel structural parts after chamfering are shot blasted with steel shot abrasives with an average particle size of 0.6 mm to remove scale, rust and other pollutants, and obtain an average roughness of 39 μm to reduce Residual stress in the production of steel structural parts, reducing pickling time and obtaining higher adhesion of zinc layer;

[0036] (3) Hot-dip galvanizing: The steel structure after shot blasting is pickled first and then dipped into the zinc pool for galvanizing. The pickling time is 54 minutes, and the volume of the zinc pool is 149m 3 , The t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| mean roughness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com