Micro-vibration sensitive type high-damping composite and preparation method thereof

A composite material and high damping technology, which is applied in the field of high damping composite materials, can solve the problems of poor damping performance and uneven distribution of ceramic phases, and achieve good thermal stability and wide service temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

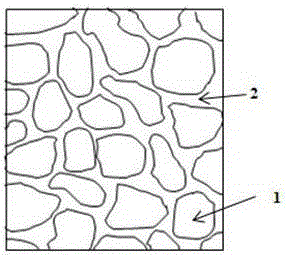

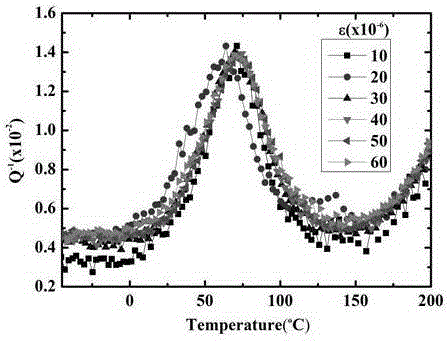

Image

Examples

Embodiment 1

[0033] Weigh 10 grams of lithium-lanthanum-zirconium-oxygen powder doped with aluminum in the lithium position and niobium in the zirconium position and 90 g of brass powder with a particle size of 500 μm and put it into a ball mill Dry milling in the tank to make it fully mixed, the speed of the ball milling tank is 200rpm, the ball milling time is 4h, the ball-to-material ratio is 4:1; the fully mixed mixture is passed through hot pressing at a sintering temperature of 750°C and a pressing pressure of 100MPa. Vacuum sintering to prepare high damping composite materials.

Embodiment 2

[0035] Same as Example 1, the difference is that the lithium lanthanum zirconium oxide powder is partially doped with aluminum in the lithium site, strontium in the lanthanum site, and silicon in the same position in the lithium lanthanum zirconium oxide powder. Damping compound.

Embodiment 3

[0037] Same as Example 1, the difference is that the brass powder is copper-aluminum alloy, and a high-damping composite material is prepared.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com