A kind of nano ceramic material composition and standard capacitor and preparation method thereof

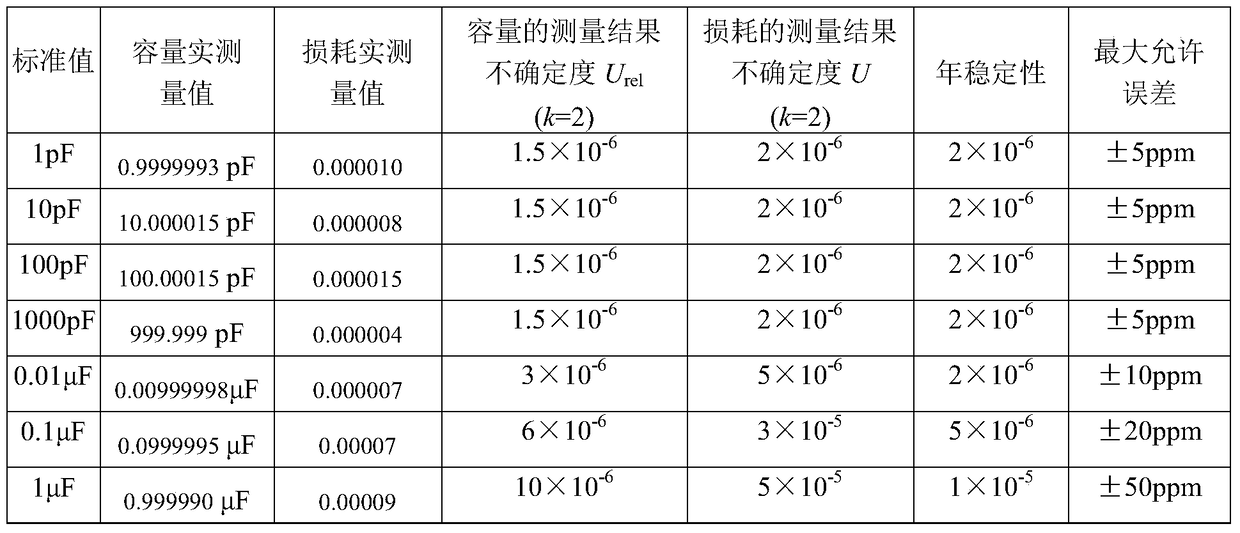

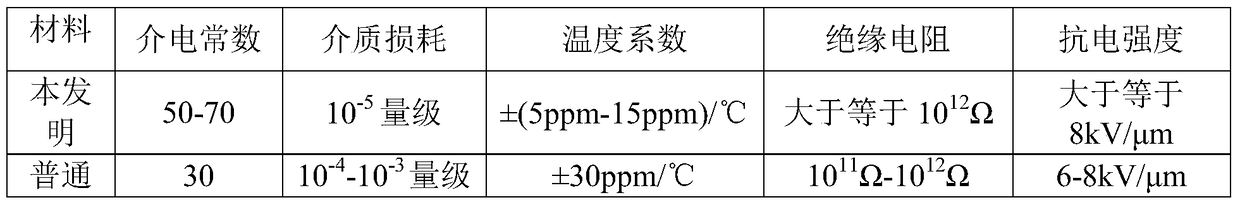

A material composition and nano-ceramic technology, applied in the field of precision electromagnetic measurement, can solve the problems of large loss factor, narrow capacity range, and low accuracy level, and achieve the effects of small loss factor, wide capacity range, and high dielectric strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

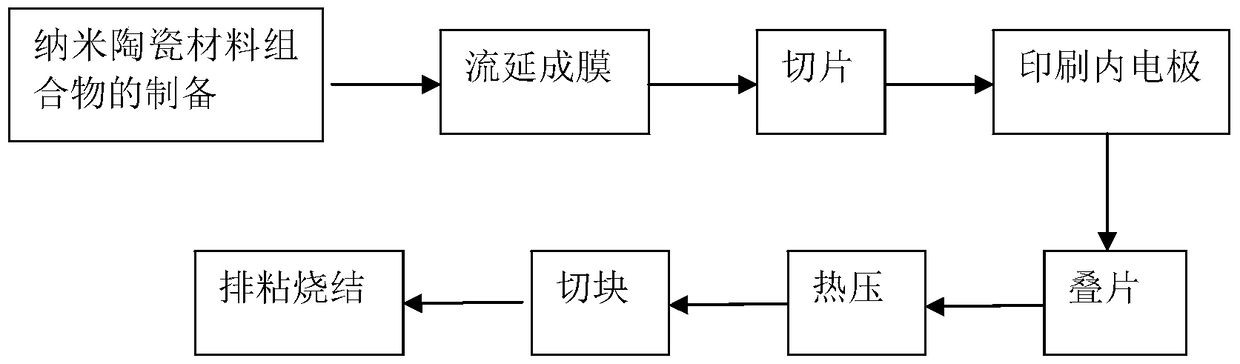

[0024] The present invention also provides a kind of preparation method of nano-ceramic material composition, and this method comprises the following steps:

[0025] (1) Nanoization: grind the ceramic material to the nanometer level; the particle size is less than or equal to 10 -9 m;

[0026] (2) Fine crystallization: adding nano-material additives to the nano-sized ceramic material; the addition method is, for example, grinding and adding;

[0027] (3) Porcelainization: Add glass frit sintering aid to the finely crystallized ceramic material, and sinter it into porcelain at 1300-1400°C for 2-4 hours.

[0028] The present invention also provides a standard capacitor and a preparation method thereof, wherein the dielectric of the capacitor is the nanometer ceramic material composition. The preparation method comprises the following steps: preparation of nano-ceramic material composition, casting into film, slicing, printing internal electrodes, stacking, hot pressing, cuttin...

Embodiment 1

[0032] Preparation of nano-ceramic material composition: grind 97g of ceramic material to nano-scale; particle size is less than or equal to 10 - 9 m; Add 1.8g SiO to the nano-sized ceramic material 2 ; Then add 1.2gB to the fine-grained ceramic material 2 o 3 -ZnO-Nd 2 o 3 -Bi 2 o 3 -SiO 2 -Li 2 O, and sintered into porcelain at 1300 ° C, the sintering time is 3 hours.

Embodiment 2

[0034] Preparation of nano-ceramic material composition: grind 98.5g of ceramic material to nano-scale; particle size is less than or equal to 10 -9 m; Add 1.0g CeO to the nano-sized ceramic material 2 ; Add 0.5g B to the fine-grained ceramic material 2 o 3 -ZnO-Bi 2 o 3 -Nd 2 o 3 , and sintered into porcelain at 1350 ° C, the sintering time is 4 hours.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com