Carrier TiO2 and preparation method as well as application thereof

A carrier and supported catalyst technology, which is applied in the direction of catalyst carriers, chemical instruments and methods, and oxidation preparation of carbonyl compounds, etc., can solve the problems of unreported catalytic performance, achieve large industrial application value, high activity, and good repeatability of results Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

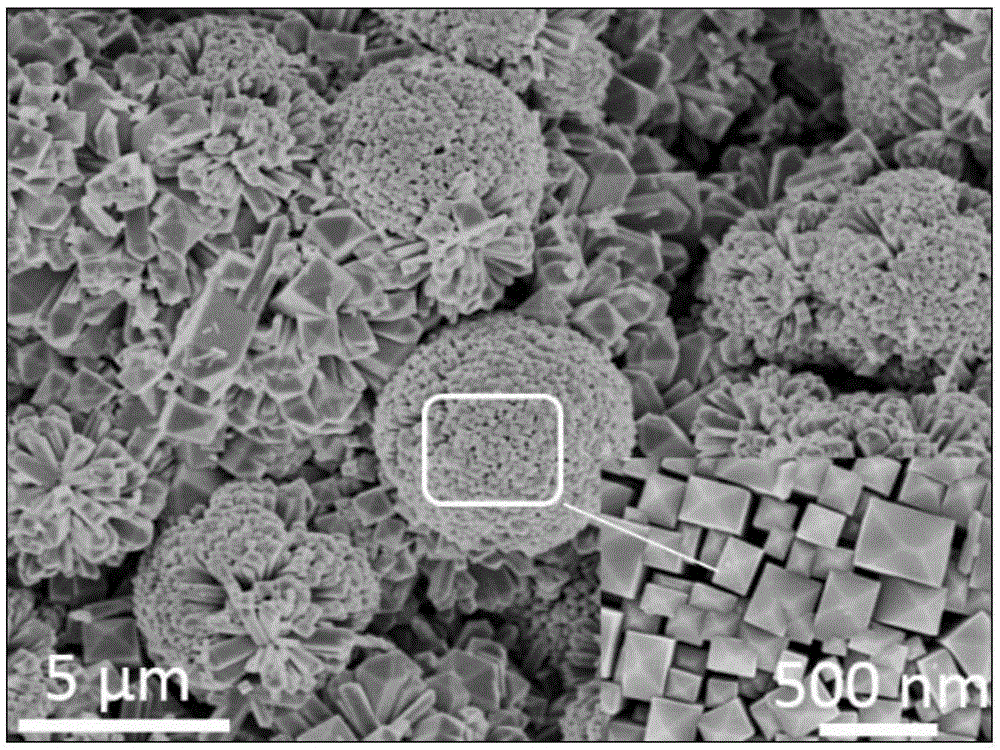

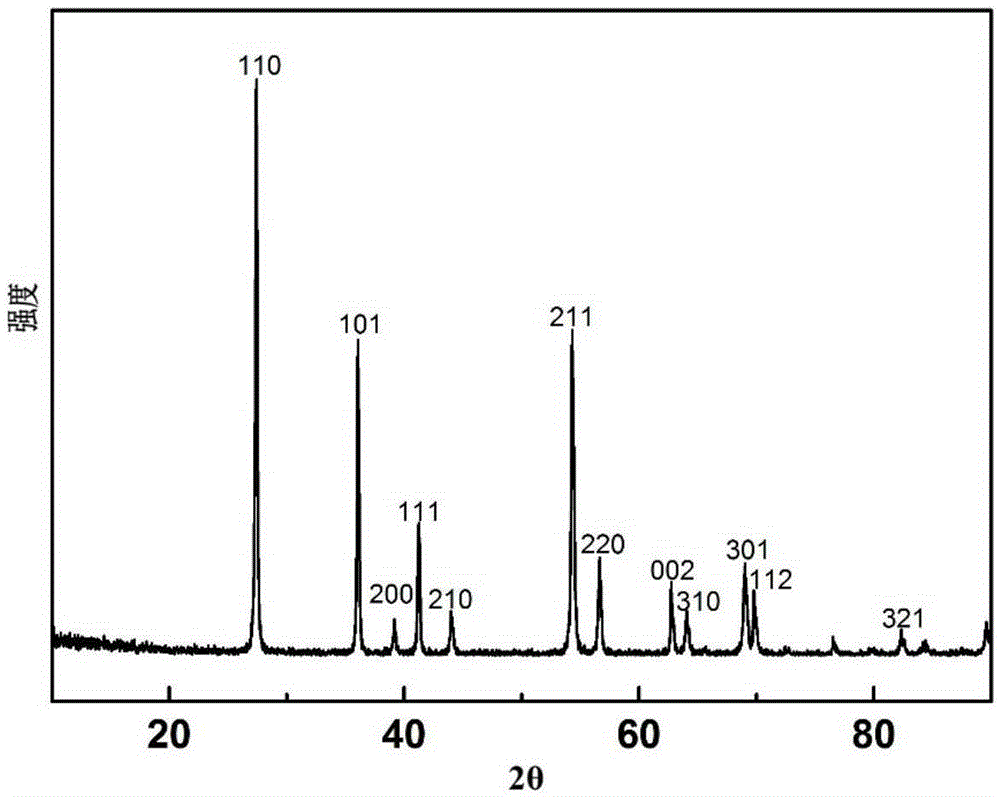

Embodiment 1

[0042] Weigh 0.400g of Ti powder and add 20mL HCl (0.5mol / L), stir in a beaker for 30min, mix well, pour into a hydrothermal kettle, heat at 180°C for 20h, cool to room temperature, continue to heat at 220°C for 10h, and obtain the product Centrifuge and wash three times with absolute ethanol. After washing, dry in vacuum at 60°C for 12h to obtain columnar TiO 2 Powder A, see SEM picture figure 1 ,TiO 2 Powder A is spherical, and the spherical surface is composed of multiple columnar structures; the XRD pattern is shown in image 3 . Prepare histidine to 0.1mol / L, additionally add HAuCl 4 ·3H 2 O was prepared to be 0.01mol / L, and the two solutions were mixed with histidine and HAuCl at room temperature 4 ·3H 2 The molar ratio of O is 20:1, placed at 20°C for 2 hours, and the yellow Au 10 Aqueous solution of B. Put A into B solution in a certain mass ratio (Au / TiO 2 =0.01, mass ratio), stirred at room temperature for 12h, stirred and dispersed evenly, and then rotated ...

Embodiment 2

[0045] Weigh 0.400g of Ti powder, add 20mL HCl (0.5mol / L), stir in a beaker for 30min, mix well, pour into a hydrothermal kettle, heat at 120°C for 40h, cool to room temperature, continue to heat at 220°C for 10h, and obtain the product Centrifuge and wash three times with absolute ethanol. After washing, dry in vacuum at 70°C for 15 hours to obtain columnar TiO 2 Powder A, see SEM picture figure 1 ,TiO 2 Powder A is spherical, and the spherical surface is composed of multiple columnar structures. Prepare histidine to 0.1mol / L, additionally make HAuCl 4 ·3H 2 O was prepared to be 0.01mol / L, and the two solutions were mixed with histidine and HAuCl at room temperature 4 ·3H 2 The molar ratio of O is 20:1, placed at 20°C for 2 hours, and the yellow Au 10 Aqueous solution of B. Put A into B solution in a certain mass ratio (Au / TiO 2 =0.01, mass ratio), stirred at room temperature for 15 hours, stirred and dispersed evenly, and then rotary evaporated at 50° C. After rotary...

Embodiment 3

[0048] Weigh 0.400g Ti powder, add 20mL HCl (1mol / L), stir in a beaker for 30min, mix well, pour into a hydrothermal kettle, heat at 140°C for 30h, cool to room temperature, continue to heat at 220°C for 10h, centrifuge after obtaining the product , and washed three times with absolute ethanol, after the washing was completed, vacuum-dried at 80°C for 12h to obtain the columnar structure TiO 2 Powder A, see SEM picture figure 1 ,TiO 2 Powder A is spherical, and the spherical surface is composed of multiple columnar structures. Prepare histidine to 0.1mol / L, additionally add HAuCl 4 ·3H 2 O was prepared to be 0.01mol / L, and the two solutions were mixed with histidine and HAu at room temperature 4 ·3H 2 The molar ratio of O is 20:1, placed at 25°C for 2 hours, and the yellow Au 10 Aqueous solution of B. Put A into B solution in a certain mass ratio (Au / TiO 2 = 0.01, mass ratio), stirred at room temperature for 12 hours, stirred and dispersed evenly, and then rotated at 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com