Heat dissipation device for electronic equipment

A technology for heat sinks and electronic equipment, applied in the direction of cooling/ventilation/heating transformation, etc., can solve the problems of low heat capacity of the thermally conductive support 120, inability to export heat from heating devices, and prone to local hot spots, etc., so as to improve the user experience and increase the thickness. , the effect of reducing the spacing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Hereinafter, preferred embodiments of the present invention will be described in detail with reference to the accompanying drawings. Note that, in this specification and the drawings, steps and elements having substantially the same are denoted by the same reference numerals, and repeated explanations of these steps and elements will be omitted.

[0021] Reference throughout this specification to "one embodiment" or "an embodiment" means that a particular feature, structure, or characteristic described in connection with the described embodiment is included in at least one of the described embodiments. Thus, appearances of the phrases "in one embodiment" or "in an embodiment" in the specification are not necessarily all referring to the same embodiment. Furthermore, the particular features, structures or characteristics may be combined in any suitable manner in one or more embodiments.

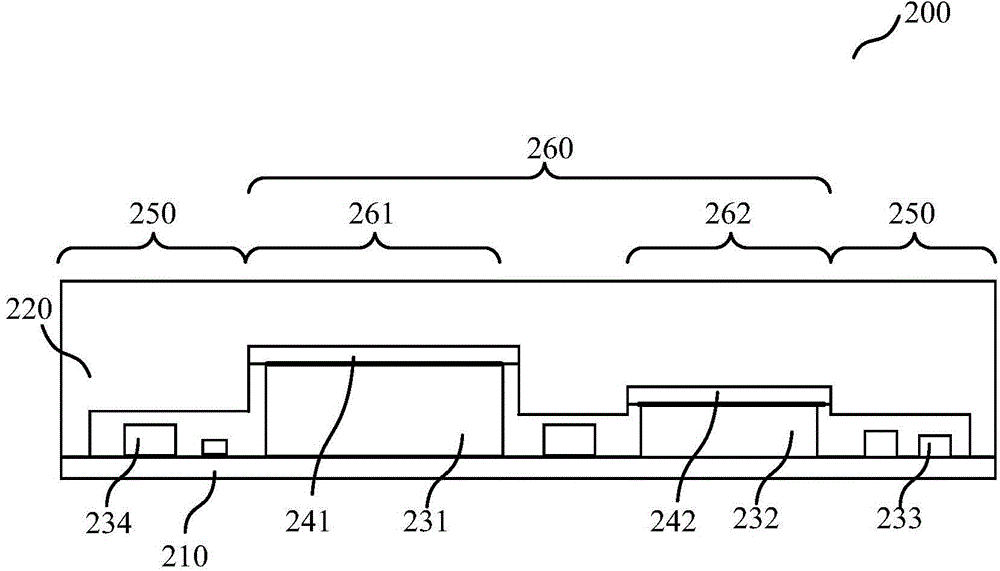

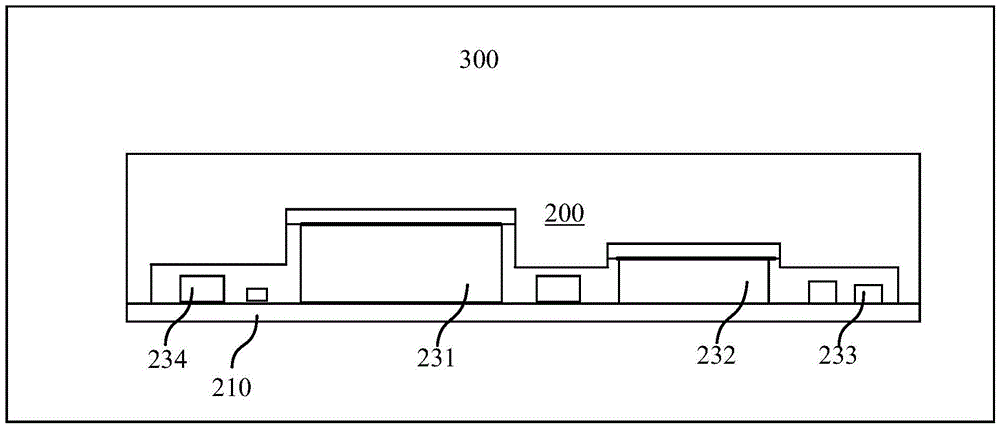

[0022] Below, will refer to figure 2 To describe a heat sink for an electronic d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com