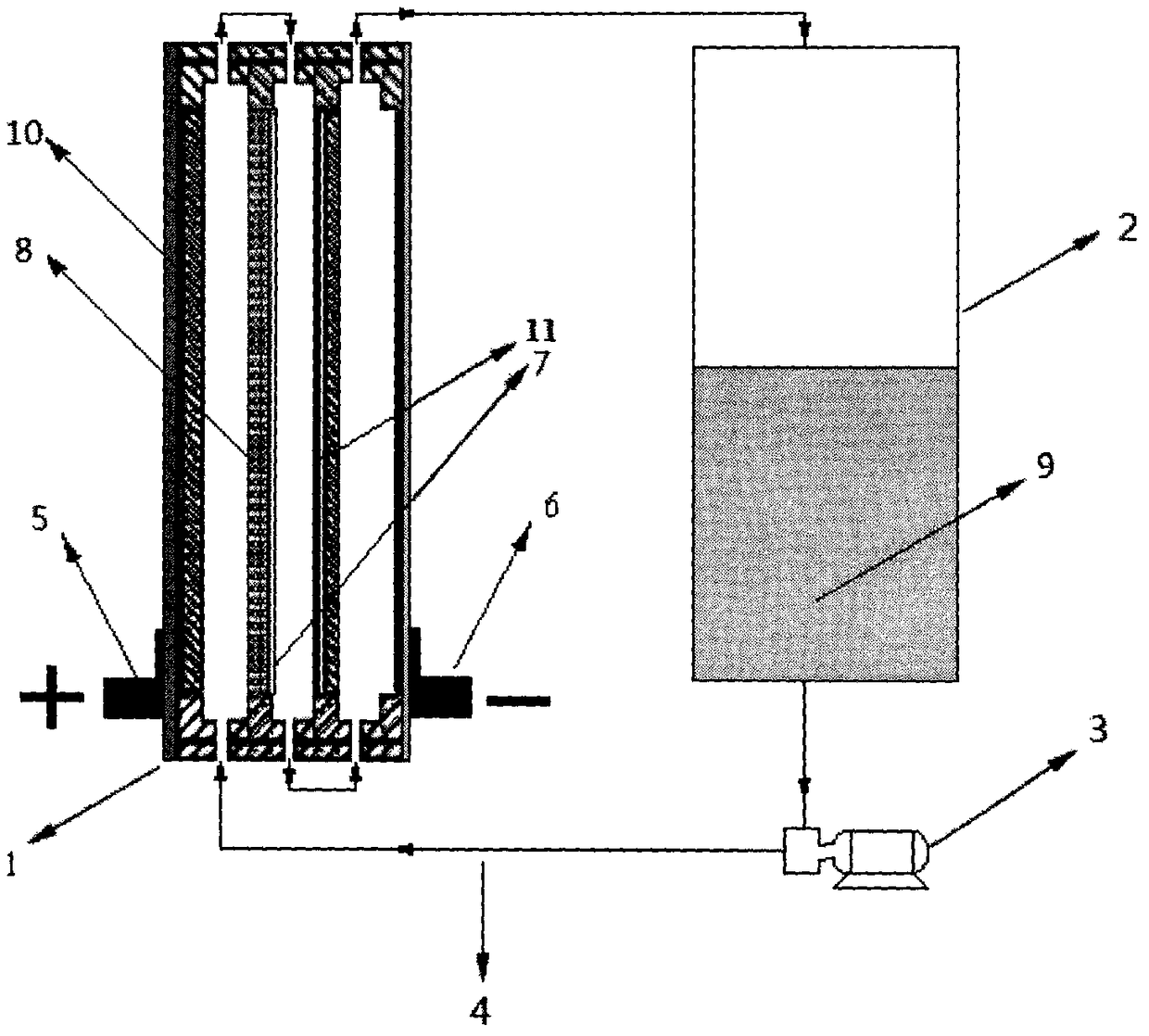

An aqueous zinc-manganese single-flow battery

A flow battery, zinc-manganese single technology, applied in fuel cells, regenerative fuel cells, circuits, etc., can solve problems such as low capacity, and achieve the effects of fast charging and discharging rate, simple manufacturing process, and high specific capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Positive electrode preparation: conductive agent acetylene black, active material, and binder PTFE are uniformly mixed according to the mass ratio of 10:85:5 to prepare a slurry, which is evenly scraped on the stainless steel net collector by wet scraping, and dried , rolling, and cutting, it can be used as the positive electrode of the zinc-manganese single flow battery.

Embodiment 2

[0024] Negative electrode preparation: Roll the copper strip to about 50um, and use a punching machine to make holes with a diameter of 20-30um on the copper strip to obtain a perforated copper strip with a porosity of 20-50%, and then punch the copper strip. Galvanized. Properly cutting the galvanized punched copper strip can be used as a negative electrode collector for a zinc-manganese single flow battery in a neutral aqueous medium. It can also be used after electroplating galvanized tin alloy.

Embodiment 3

[0026] Electrolyte preparation: weigh ZnSO 4 161g, MnSO 4 75g, 142g of sodium sulfate was dissolved in 500mL of deionized water. Weigh 5g of cetyltrimethylammonium bromide, 5g of polyethylene glycol and 5g of BiCl 3 Dissolve in 300mL water. The above two solutions were mixed evenly, and the fixed volume was 1L. Prepare an appropriate amount of electrolyte and place it in the electrolyte storage tank.

PUM

| Property | Measurement | Unit |

|---|---|---|

| energy conversion efficiency | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com