Negative electrode active material, preparation method thereof, and lithium ion battery

A technology of negative electrode active materials and outer layer materials, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of poor cycle performance and rate performance of negative electrode active materials, improve dispersion uniformity and conductivity, and avoid swelling Effect, environmental friendliness and pollution-free effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] The present invention also provides a preparation method of the above-mentioned negative electrode active material, comprising the following steps:

[0035] S1. Provide a dispersion liquid containing silicon particles and a dispersion solvent;

[0036] S2, mixing multilayer graphene oxide with the dispersion liquid, then performing ultrasonic intercalation treatment, filtering and drying to obtain the first precursor;

[0037] Then subjecting the first precursor to a thermal reduction treatment in a non-oxidizing atmosphere, and cooling to obtain a second precursor;

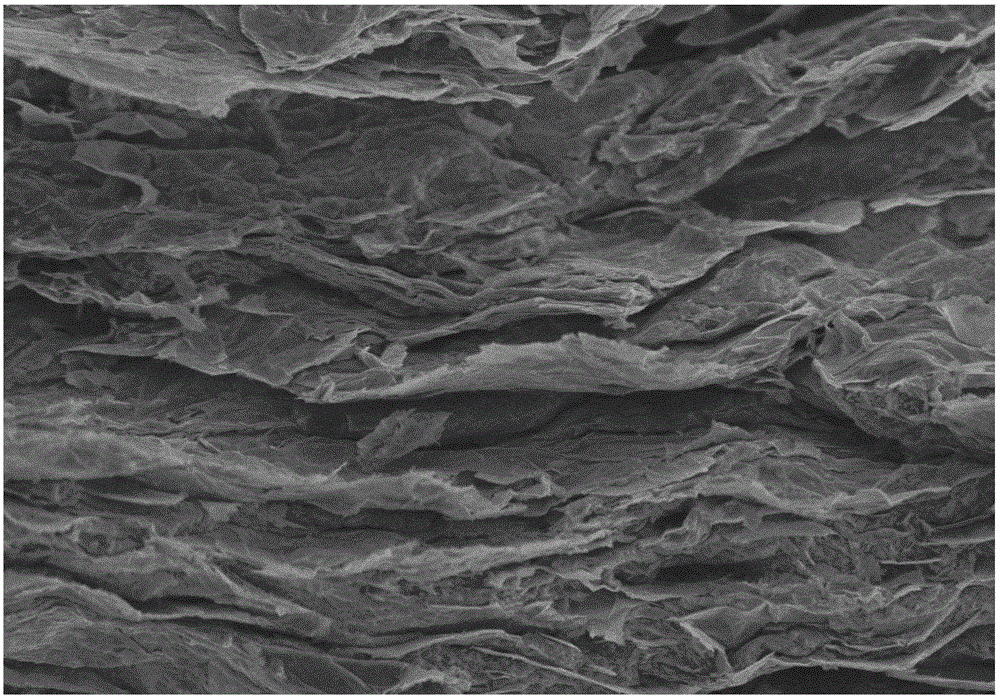

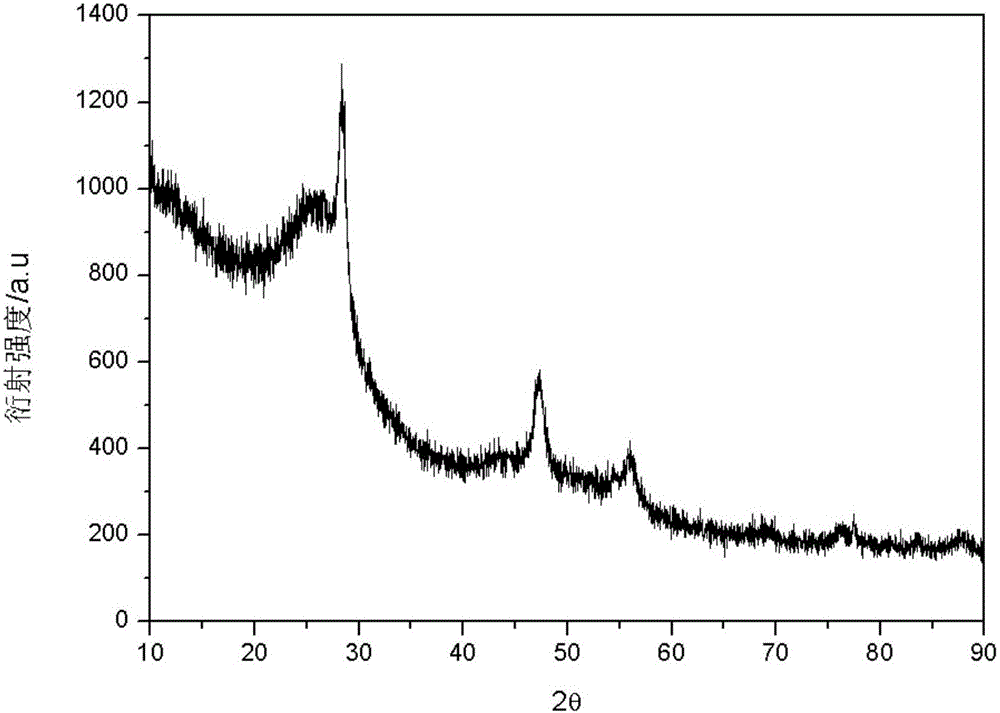

[0038] S3. Mechanically modifying the second precursor to obtain an inner layer material; the inner layer material includes multi-layer graphene and silicon particles; the multi-layer graphene has a plurality of stacked sheets, corresponding to The spacing between adjacent sheets is 20-500nm;

[0039] S4. Forming a carbon layer on the surface of the inner layer material to obtain the outer layer material...

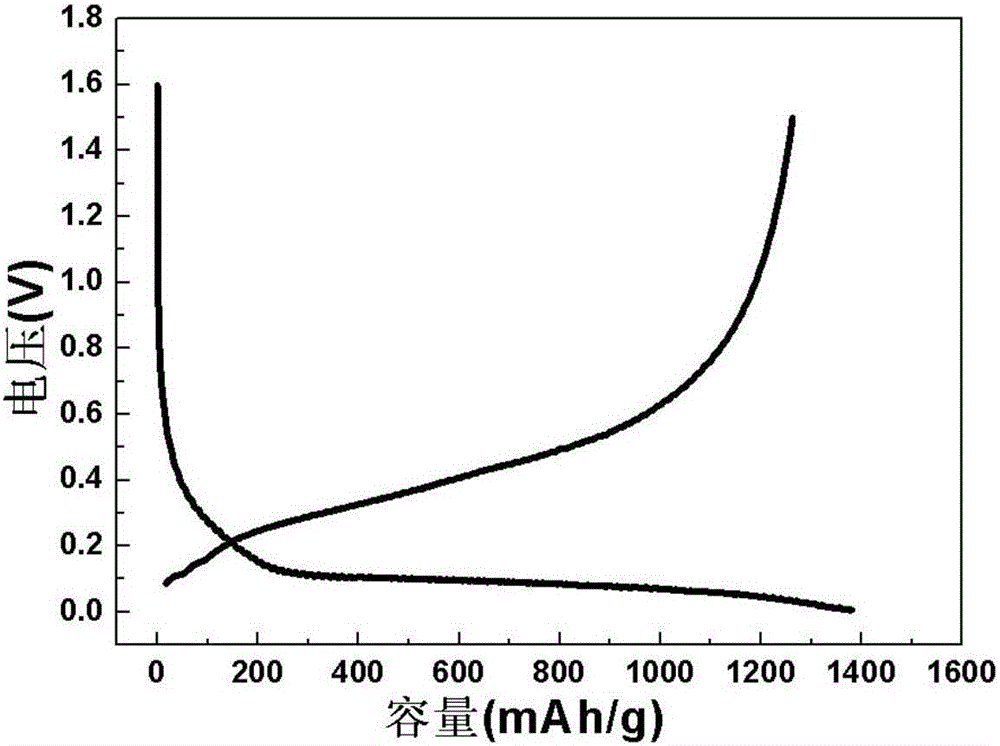

Embodiment 1

[0105] This example is used to illustrate the negative electrode active material disclosed in the present invention and its preparation method.

[0106] (1) Preparation of dispersion

[0107] Disperse 3g of nano-silicon particles (with a median diameter of 50nm) into a mixture of 45ml of absolute ethanol and 5ml of deionized water, ultrasonically disperse for 1h, then heat at 50°C in a nitrogen atmosphere, and add 0.3 g of γ-methacryloxypropyltrimethoxysilane was reacted for 24 hours to obtain a dispersion liquid comprising nano-silicon particles modified by γ-methacryloxypropyltrimethoxysilane.

[0108] (2) Preparation of the second precursor

[0109] First, prepare multilayer graphene oxide: by the improved Staudenmaier method, add 36ml of concentrated sulfuric acid and 18ml of concentrated nitric acid into a round bottom flask, add 2g of natural flake graphite under ice bath and magnetic stirring, and slowly Add 22g of potassium chlorate, and absorb the chlorine gas produ...

Embodiment 2

[0118] This example is used to illustrate the negative electrode active material disclosed in the present invention and its preparation method.

[0119] (1) Preparation of the first precursor

[0120] Disperse 3g of nano-silicon particles (with a median diameter of 50nm) into a mixture of 45ml of absolute ethanol and 5ml of deionized water, ultrasonically disperse for 1h, then heat at 50°C in a nitrogen atmosphere, and add 0.3 g of γ-methacryloxypropyltrimethoxysilane was reacted for 24 hours to obtain a dispersion liquid comprising nano-silicon particles modified by γ-methacryloxypropyltrimethoxysilane.

[0121] (2) Preparation of the second precursor

[0122] First, prepare multilayer graphene oxide: by the improved Staudenmaier method, add 36ml of concentrated sulfuric acid and 18ml of concentrated nitric acid into a round bottom flask, add 2g of natural flake graphite under ice bath and magnetic stirring, and slowly Add 22g of potassium chlorate, and absorb the chlorine ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com