Ammonia nitrogen adsorbing material and preparation method thereof

An adsorption material, ammonia nitrogen technology, applied in chemical instruments and methods, adsorption water/sewage treatment, other chemical processes, etc., can solve the problem that is not suitable for the treatment of large-flow and high-concentration nitrogen-containing wastewater, and the high requirements for the safe use and storage of liquid chlorine , high operation and management costs, etc., to achieve the effect of high market application prospects, simple and feasible preparation method, and good ammonia nitrogen adsorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

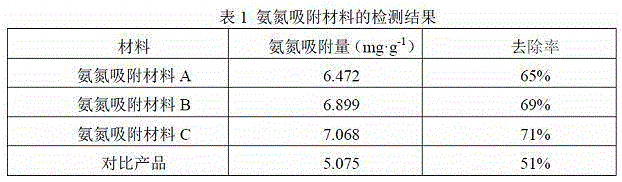

Embodiment 1

[0031] The ammonia nitrogen adsorption material was prepared according to the following steps:

[0032] (1) Select 100g of a sediment sample, freeze-dry it at -80°C, grind it into powder, and pass it through a 100-mesh sieve to obtain a sediment powder;

[0033] (2) Under the condition of feeding nitrogen, anaerobically heat the sediment powder at 600°C for 2 hours;

[0034] (3) Washing the natural zeolite with deionized water, drying and grinding into powder, and passing through a 100-mesh sieve to obtain natural zeolite powder;

[0035] (4) Mix the heated sediment powder and natural zeolite powder uniformly at a mass ratio of 7:3 to obtain material A.

Embodiment 2

[0037] The ammonia nitrogen adsorption material was prepared according to the following steps:

[0038] (1) Select 100g of a sediment sample, freeze-dry it at -80°C, grind it into powder, and pass it through a 100-mesh sieve to obtain a sediment powder;

[0039] (2) Under the condition of feeding nitrogen gas, anaerobically heat the sediment powder at 500°C for 2 hours;

[0040] (3) Washing the natural zeolite with deionized water, drying and grinding into powder, and passing through a 100-mesh sieve to obtain natural zeolite powder;

[0041] (4) Mix the heated sediment powder and natural zeolite powder evenly according to the mass ratio of 7:3 to obtain the mixed powder;

[0042] (5) Put the mixed powder into 1mol / L NaCl solution and stir for 2 hours, filter the solution to obtain material B (modified ammonia nitrogen adsorption material).

Embodiment 3

[0044] The ammonia nitrogen adsorption material was prepared according to the following steps:

[0045] (1) Select 100g of a sediment sample, freeze-dry it at -80°C, grind it into powder, and pass it through a 100-mesh sieve to obtain a sediment powder;

[0046] (2) Under the condition of feeding nitrogen, anaerobically heat the sediment powder at 600°C for 2 hours;

[0047] (3) Washing the natural zeolite with deionized water, drying and grinding into powder, and passing through a 100-mesh sieve to obtain natural zeolite powder;

[0048] (4) Mix the heated sediment powder and natural zeolite powder evenly according to the mass ratio of 7:3 to obtain the mixed powder;

[0049] (5) Put the mixed powder into 1mol / L NaCl solution and stir for 2 hours, filter the solution to obtain the modified mixed material;

[0050] (6) The modified mixed material was heated at 400° C. for 2 h to obtain material C (modified and heat-treated ammonia nitrogen adsorption material).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com