Preparation method of modified polyvinylidene fluoride-polyvinyl alcohol binary composite ultrafiltration membrane

A polyvinylidene fluoride and binary composite technology, applied in the field of materials science, can solve the problems of poor hydrophilicity and poor anti-pollution performance, achieve strong anti-pollution performance, easy to obtain, improve pure water flux and flux recovery rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

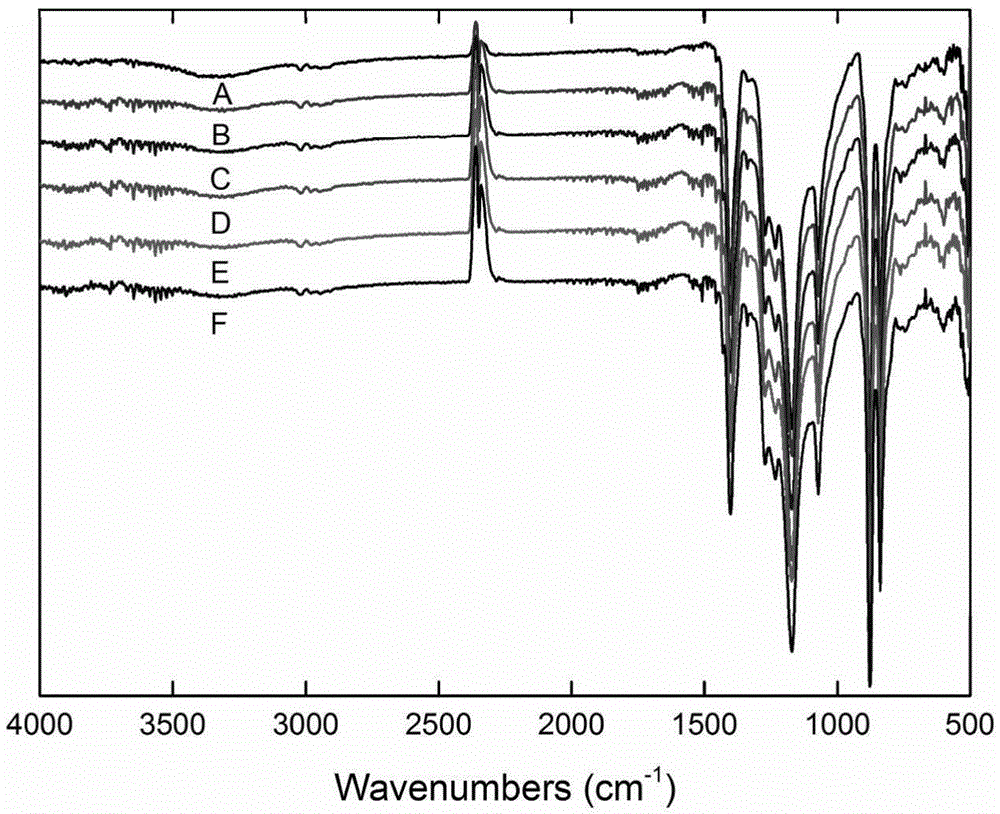

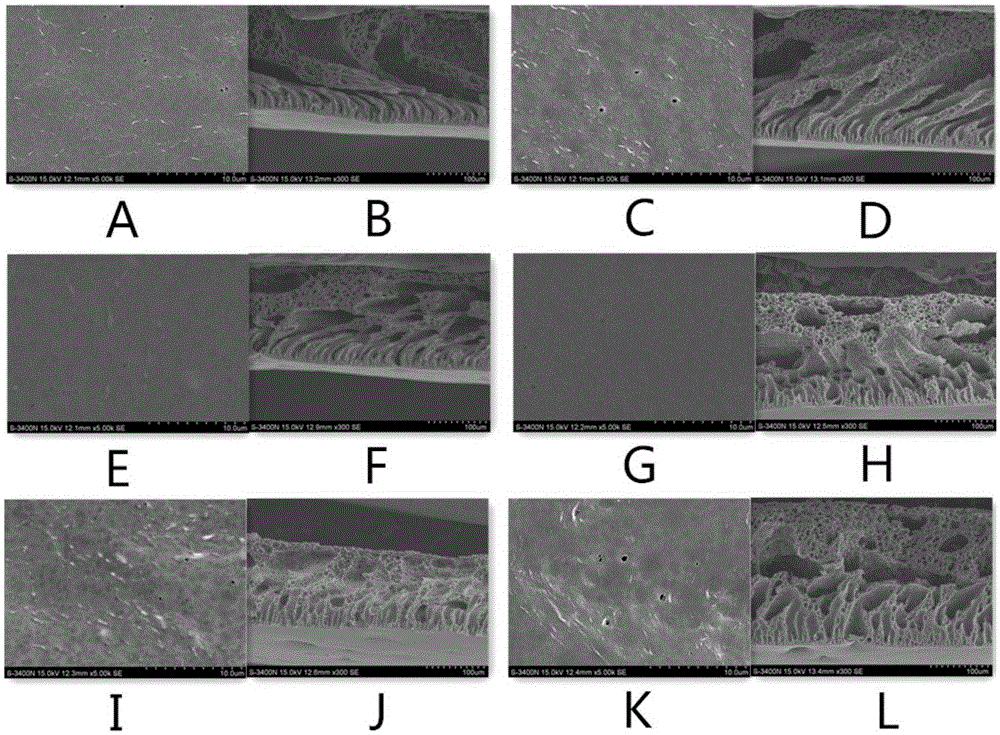

[0018] Add 0.03wt.% carboxylated multi-walled carbon nanotubes to 82wt.% dimethyl sulfoxide solvent, ultrasonically disperse for 10 minutes; then add a total of 18wt.% polyvinylidene fluoride and polyvinyl alcohol powder to form a binary film Materials, control the temperature at 95°C, and mechanically stir for 12 hours to dissolve to obtain the casting solution;

[0019] Then, after fully defoaming the obtained casting solution at 50°C, scrape the film on the glass plate;

[0020] Then immerse the glass plate with a thin layer of casting solution into a gel bath at 25°C to form a phase-separated film, then soak it in deionized water for 7 days, take it out, and dry it naturally in the air to obtain the modified carboxylated multi-walled carbon nanotubes. The polyvinylidene fluoride-polyvinyl alcohol binary composite ultrafiltration membrane;

[0021] In the binary membrane material composed of polyvinylidene fluoride and polyvinyl alcohol, polyvinylidene fluoride and polyvin...

Embodiment 2

[0025] Add 0.06wt.% carboxylated multi-walled carbon nanotubes to 82wt.% dimethyl sulfoxide solvent, ultrasonically disperse for 10 minutes; then add a total of 18wt.% polyvinylidene fluoride and polyvinyl alcohol powder to form a binary film Materials, control the temperature at 105°C, and mechanically stir for 12 hours to dissolve to obtain the casting solution;

[0026] Then, after fully defoaming the obtained casting solution at 60°C, scrape the film on the glass plate;

[0027] Then immerse the glass plate with a thin layer of casting solution into a gel bath at 30°C to form a phase-separated film, then soak it in deionized water for 5 days, take it out, and dry it naturally in the air to obtain the modification of carboxylated multi-walled carbon nanotubes The polyvinylidene fluoride-polyvinyl alcohol binary composite ultrafiltration membrane;

[0028] In the binary membrane material composed of polyvinylidene fluoride and polyvinyl alcohol, polyvinylidene fluoride and ...

Embodiment 3

[0032] Add 0.09wt.% carboxylated multi-walled carbon nanotubes to 82wt.% dimethyl sulfoxide solvent, ultrasonically disperse for 10 minutes; then add a total of 18wt.% polyvinylidene fluoride and polyvinyl alcohol powder to form a binary film Materials, control the temperature at 100°C, and mechanically stir for 12 hours to dissolve to obtain the casting solution;

[0033] Then, after fully defoaming the obtained casting solution at 60°C, scrape the film on the glass plate;

[0034] Then immerse the glass plate with a thin layer of casting solution into a gel bath at 30°C to form a phase-separated film, then soak it in deionized water for 5 days, take it out, and dry it naturally in the air to obtain the modification of carboxylated multi-walled carbon nanotubes The polyvinylidene fluoride-polyvinyl alcohol binary composite ultrafiltration membrane;

[0035] In the binary membrane material composed of polyvinylidene fluoride and polyvinyl alcohol, polyvinylidene fluoride and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com