Determination method of content of fusel in ethylene carbonate

A ethylene carbonate and determination method technology, applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problems of large damage to the injection needle, poor precision, easy crystallization, etc., and achieve the effect of improving accuracy and accurate detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

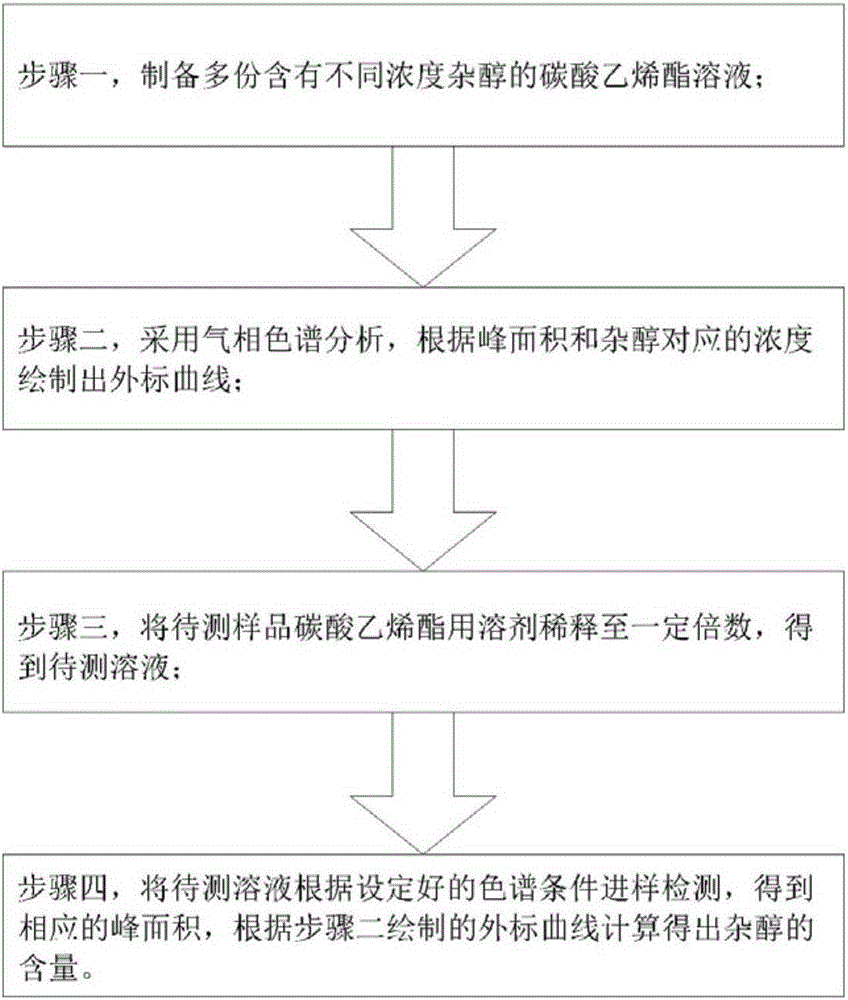

Method used

Image

Examples

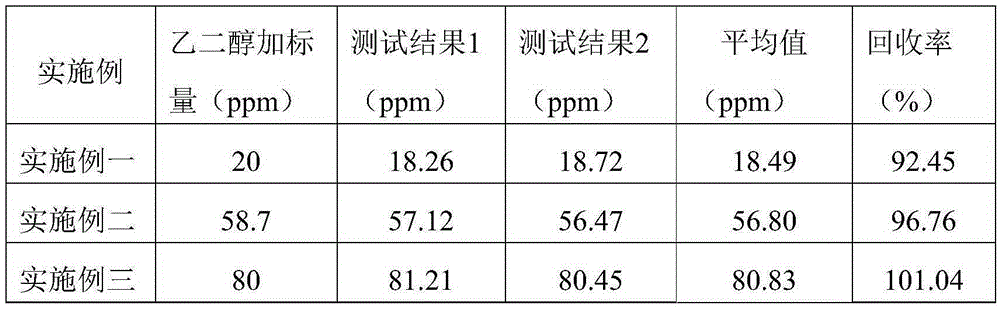

Embodiment 1

[0028] (a) Put the ethylene carbonate in an oven to melt, after the melting is complete, use a needle to measure 400mL of the melted ethylene carbonate into a 500mL volumetric flask, and then use acetone to dilute to a certain dilution factor obtained by the graduation line ’S stock solution;

[0029] (b), respectively weigh about 0.1g of ethylene glycol and diethylene glycol in a 100mL volumetric flask, use the solution in (a) to make up to the mark to obtain the standard of ethylene glycol and diethylene glycol with a concentration of 1000ppm liquid;

[0030] (c) To prepare standard samples with different concentration gradients of the 1000 ppm ethylene glycol and diethylene glycol standard solutions in (b), the stock solution in (a) should be used as the diluent;

[0031] (d), set the chromatographic conditions:

[0032] Chromatographic column: DB-WAXETR (60m*0.32mm*0.32um) Inlet temperature: 250℃; detector temperature 250℃; sampling mode: splitless injection; split ratio 20:1; co...

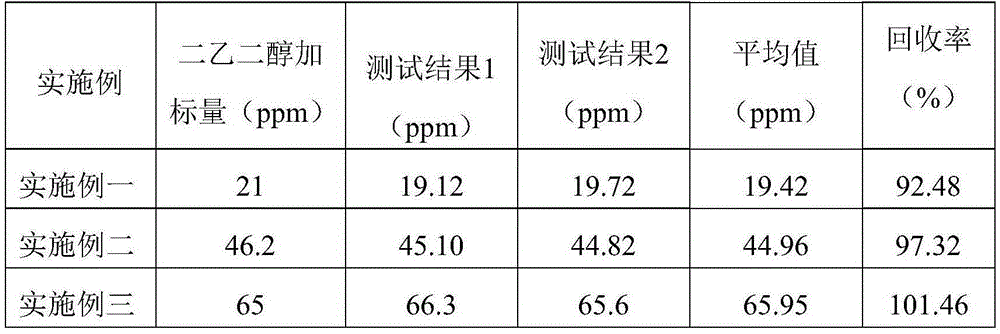

Embodiment 2

[0036] (a) Put the ethylene carbonate in an oven to melt. After the melting is complete, use a needle to measure 400mL of the melted ethylene carbonate into a 500mL volumetric flask, and then use benzene to dilute to a certain dilution factor obtained by the graduation line ’S stock solution;

[0037] (b), respectively weigh about 0.1g of ethylene glycol and diethylene glycol in a 100mL volumetric flask, use the solution in (a) to make up to the mark to obtain the standard of ethylene glycol and diethylene glycol with a concentration of 1000ppm liquid;

[0038] (c), according to the needs, prepare the standard samples of 1000 ppm ethylene glycol and diethylene glycol in (b) into standard samples with different concentration gradients, and use the stock solution in (a) as the diluent;

[0039] (d), set the chromatographic conditions:

[0040] Chromatographic column: DB-FFAP, inlet temperature: 250°C; detector temperature: 250°C; sampling mode: splitless injection; split ratio 20:1; co...

Embodiment 3

[0044] (a) Put the ethylene carbonate in an oven to melt, after the melting is complete, use a needle to measure 400mL of the melted ethylene carbonate into a 500mL volumetric flask, and then use acetonitrile to dilute to a certain dilution factor obtained by the graduation line ’S stock solution;

[0045] (b), respectively weigh about 0.1g of ethylene glycol and diethylene glycol in a 100mL volumetric flask, use the solution in (a) to make up to the mark to obtain the standard of ethylene glycol and diethylene glycol with a concentration of 1000ppm liquid;

[0046] (c), according to the needs, prepare the standard samples of 1000 ppm ethylene glycol and diethylene glycol in (b) into standard samples with different concentration gradients, and use the stock solution in (a) as the diluent;

[0047] (d), set the chromatographic conditions:

[0048] Chromatographic column: DB-WAX, inlet temperature: 250°C; detector temperature: 250°C; sampling method: splitless injection; split ratio 20...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com