A High Stability Fiber Laser

A fiber laser, high-stability technology, used in lasers, laser parts, phonon exciters, etc., can solve the problems of difficult pump fiber integrity, high signal loss, and unfavorable factory mass production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

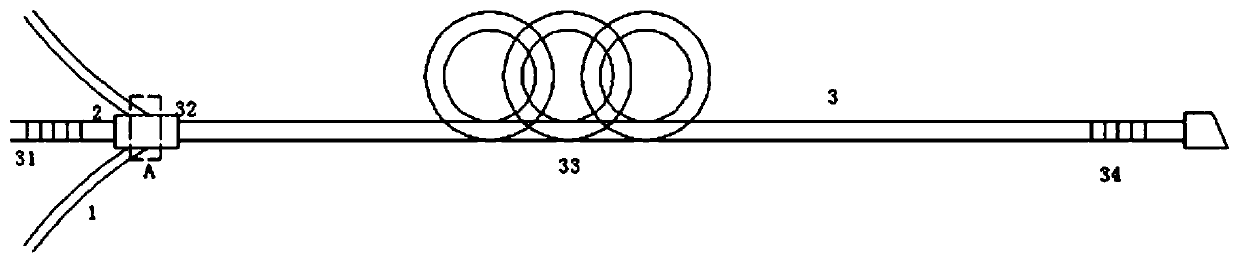

[0039] Such as figure 1 with Image 6As shown, this embodiment discloses a high-stability fiber laser, comprising a first fiber grating (31), a beam combiner (32), a gain fiber (33), and a second fiber grating (34) arranged in sequence, wherein :

[0040] A resonant cavity (3) composed of a first fiber grating (31) and a second fiber grating (34), the gain fiber (33) is arranged on the first fiber grating (31) and the second fiber grating (34) between;

[0041] The pump fiber (1) and the signal fiber (2) are side-fused to form a beam combiner (32), and the beam combiner (32) is arranged between the first fiber grating (31) and the gain fiber (33), so The gain fiber (33) is fused with the signal fiber.

[0042] After a section of the pumping fiber (1) removes the first coating layer (13), it is heated and pre-tapered to form a first tapered section, a connecting section and a second tapered section, the first tapered section, the connecting section It is connected with the...

Embodiment 2

[0050] Such as figure 2 As shown, this embodiment discloses a high-stability fiber laser. The difference from Embodiment 1 is that the fiber laser disclosed in this embodiment includes a first fiber grating (31), a gain fiber (33), a Beam combiner (32), the second fiber grating (34), wherein:

[0051] A resonant cavity (3) composed of the first fiber grating (31) and the second fiber grating (34), the beam combiner (32) is arranged between the gain fiber (33) and the second fiber grating (34), the The pumping optical fiber (1) coupled in the beam combiner (32) is used to reversely provide pumping light.

Embodiment 3

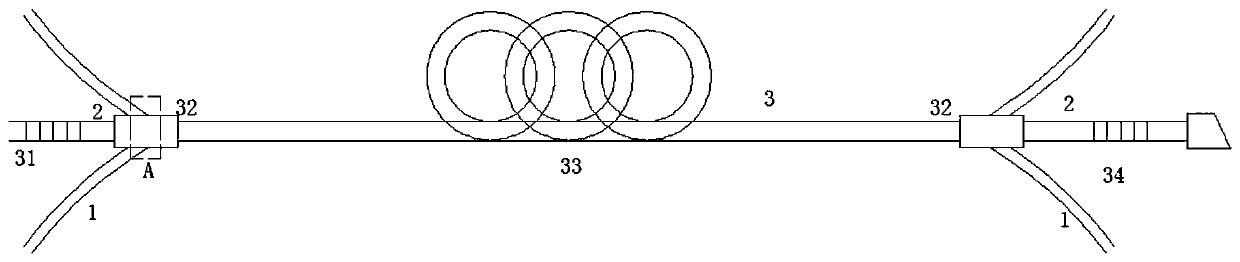

[0053] Such as image 3 As shown, this embodiment discloses a high-stability fiber laser. The difference from Embodiment 1 is that the fiber laser disclosed in this embodiment includes a first fiber grating (31) and a beam combiner (32) arranged in sequence. , gain fiber (33), beam combiner (32) and second fiber grating (34), wherein:

[0054] A resonant cavity (3) composed of a first fiber grating (31) and a second fiber grating (34), the gain fiber (33) is arranged on the first fiber grating (31) and the second fiber grating (34) between;

[0055] A beam combiner (32) is respectively arranged between the first fiber grating (31) and the gain fiber (33), between the gain fiber (33) and the second fiber grating (34), and the pump fiber (1) and the signal fiber (2) are coupled in a beam combiner (32), and the pumping fiber (1) coupled in the beam combiner (32) on both sides of the gain fiber (33) is used to provide pumping light bidirectionally .

[0056] The gain fiber (33...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com