Polypyrrole/nano-copper composite gas diffusion electrode and preparation and application thereof

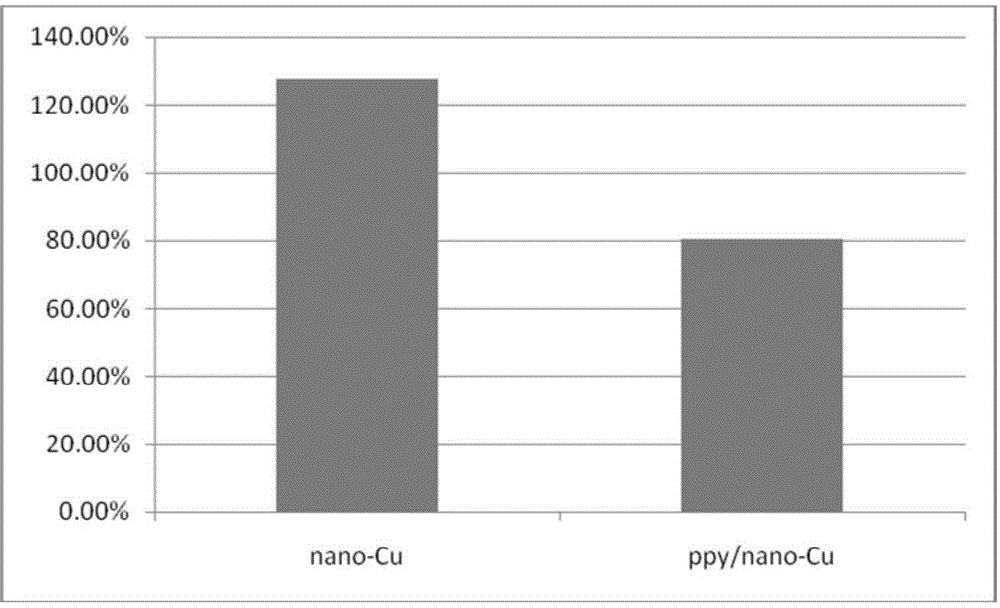

A gas diffusion electrode and composite gas technology, applied in electrodes, electrolysis processes, electrolysis components, etc., can solve the problems of difficulty in completely cracking the greenhouse effect, reduced energy utilization, high hydrogen evolution side reactions, etc. The effect of improving Faraday efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Soak Toray030 carbon paper in concentrated nitric acid for 12 hours at room temperature, rinse the soaked carbon paper three times with deionized water and absolute ethanol, and then blow dry with argon. Cut the dried carbon paper into a square carbon paper with a size of 15mm*20mm, use copper foil as the current collector, and use a polyester frame as the frame, and press it at 0.6MPa and 100 degrees for 1 minute to obtain the following: Base electrode; put the base electrode into an aqueous solution containing 0.1mol / L lithium perchlorate and 0.15mol / L pyrrole, and perform constant potential polymerization at 0.855V for 5min to obtain a polypyrrole gas diffusion electrode with a thickness of 0.3μm; Then, put the electrode into a mixed solution of 0.15 mol / L copper sulfate and 0.5 mol / L sulfuric acid, and conduct potentiostatic polymerization at -0.65 V for 5 minutes to obtain a polypyrrole / nano-copper composite gas diffusion electrode.

[0019] Soak Toray030 carbon pa...

Embodiment 2

[0022] Soak Toray060 carbon paper in concentrated nitric acid for 24 hours at room temperature, rinse the soaked carbon paper three times with deionized water and absolute ethanol, and then blow dry with argon. Cut the dried carbon paper into 15mm*20mm square carbon paper, use copper foil as current collector, use polyester frame as frame, heat press at 0.8MPa, 130 degrees for 1 minute, you can get the following Base electrode; put the base electrode into an aqueous solution containing 0.05mol / L sodium p-toluenesulfonate and 0.3mol / L pyrrole, and conduct potentiostatic polymerization at 0.855V for 5min to obtain a polypyrrole gas diffusion electrode with a thickness of 0.3μm Then, put the electrode into a mixed solution of 0.5mol / L copper sulfate and 0.5mol / L sulfuric acid, and conduct potentiostatic polymerization at -0.85V for 5min to obtain a 0.8μm polypyrrole / nano-copper composite gas diffusion electrode.

[0023] Soak Toray060 carbon paper in concentrated nitric acid for ...

Embodiment 3

[0025] Soak the carbon cloth in concentrated nitric acid for 24 hours at room temperature, rinse the soaked carbon paper three times with deionized water and absolute ethanol, and then blow dry with argon. Cut the dried carbon paper into 15mm*20mm square carbon paper, use copper foil as current collector, use polyester frame as frame, heat press at 0.6MPa, 100 degrees for 1 minute, and the substrate can be obtained electrode; put the base electrode into an aqueous solution containing 0.1mol / L potassium hydrogensulfate and 0.5mol / L pyrrole, and conduct potentiostatic polymerization at 0.855V for 5min to obtain a 0.3μm polypyrrole gas diffusion electrode; then, the Put the electrode into a mixed solution of 0.5mol / L copper sulfate and 0.5mol / L sulfuric acid, and conduct potentiostatic polymerization at -1.05V for 5min to obtain a 1.0μm polypyrrole / nano-copper composite gas diffusion electrode.

[0026] Soak the carbon cloth in concentrated nitric acid for 24 hours at room temper...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com