Preparation method of defective graphene anchored double transition metal monatomic synthesis ammonia catalyst

A transition metal and graphene technology, applied in the electrolysis process, electrodes, electrolysis components, etc., can solve problems such as the inability to obtain catalytic performance, and achieve the effect of broadening the field of catalyst preparation, improving catalyst activity, and enhancing catalyst activity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

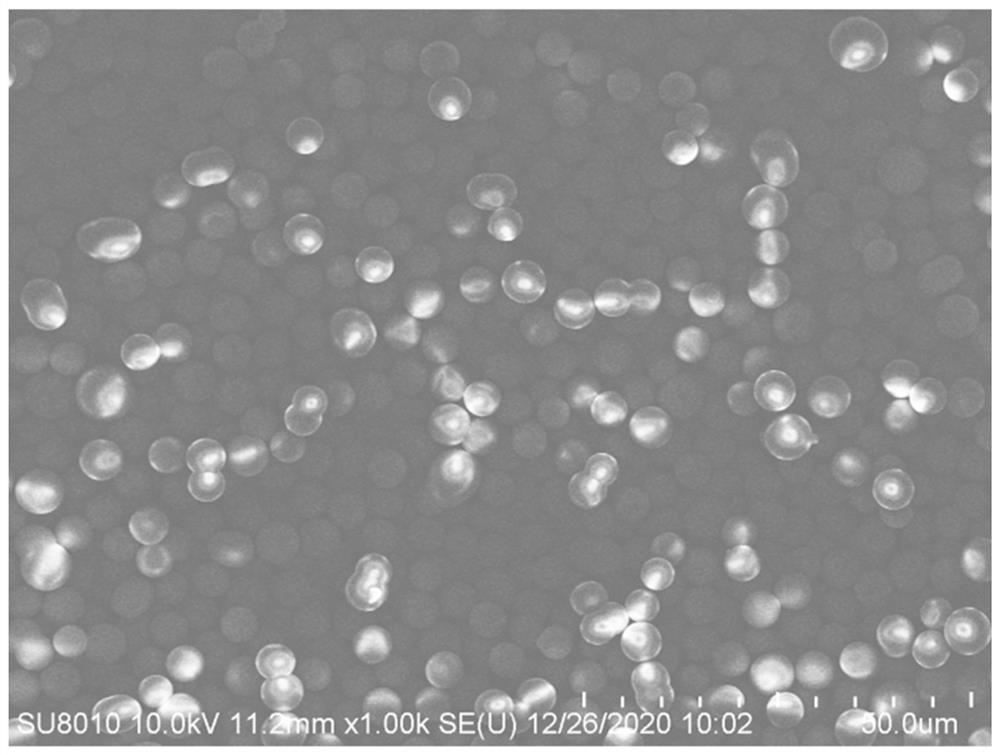

[0030] Add 1.8 g of polyvinylpyrrolidone, 18 g of styrene, and 0.3 g of azobisisobutyronitrile into a mixture of 80 mL of ethanol and 20 mL of water, stir for 12 h under the condition of nitrogen and deoxygenation, and vacuum-dry the product to obtain polyphenylene SEM pictures of ethylene microspheres and polystyrene microspheres are attached figure 1 ,From figure 1 It can be seen that the microspheres are uniform in size and dispersed evenly;

[0031] Add 1 g of polystyrene microspheres to 10 mmol / L hemin solution and ultrasonically homogenize, stir at room temperature for 12 hours, and centrifuge to wash off excess hemin;

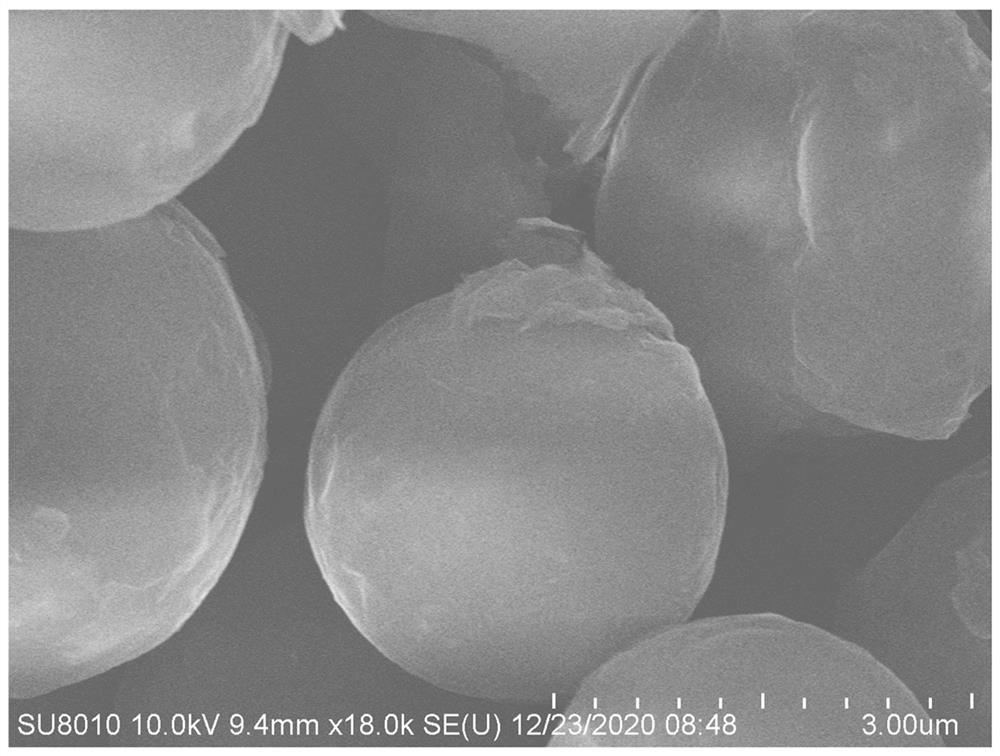

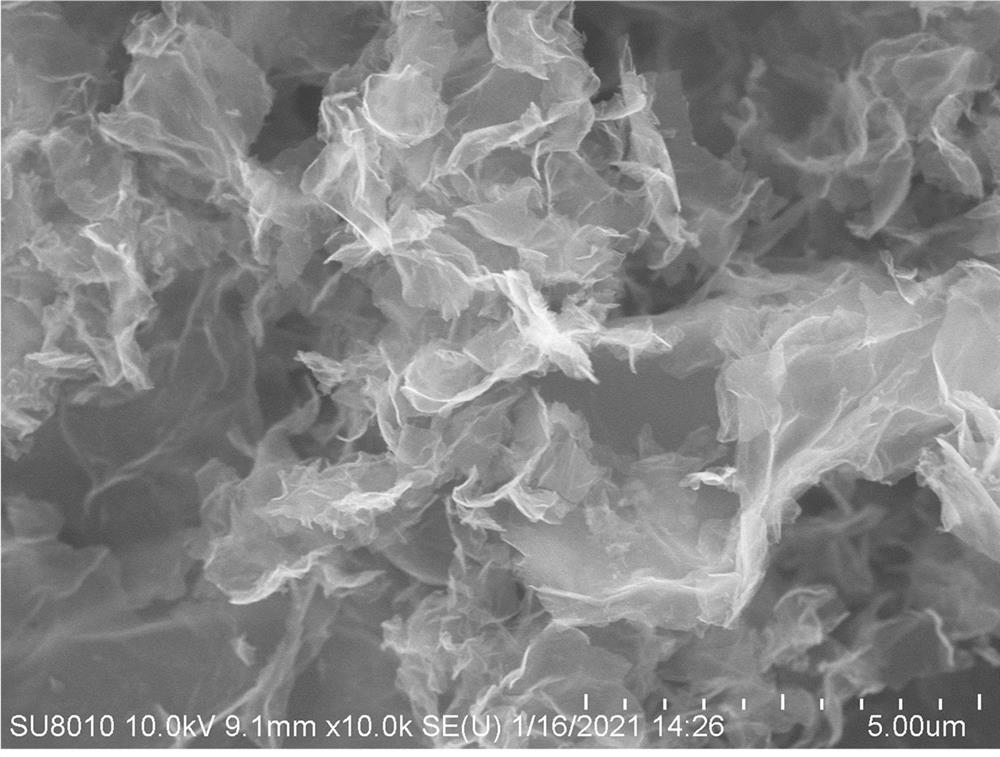

[0032] Stir 1 g of polystyrene microspheres adsorbed with hemin and 5 mg / mL defective graphene oxide aqueous solution for 24 h to form a composite structure with polystyrene microspheres as the core and defective graphene oxide as the shell, and vacuum-dry after centrifugation Defective graphene oxide-coated polystyrene microspheres are obtained, and d...

Embodiment 2

[0035] Add 1.8 g of polyvinylpyrrolidone, 15 g of styrene, and 0.2 g of azobisisobutyronitrile into a mixture of 90 mL of ethanol and 10 mL of water, stir for 12 h under the condition of purging nitrogen and removing oxygen, and vacuum-dry the product after centrifugal washing to obtain poly Styrene microspheres, SEM pictures of polystyrene microspheres are attached Figure 6 ,from Figure 6 It can be seen that the polystyrene microspheres are uniformly dispersed, the surface is smooth and the size is uniform;

[0036] Add 1 g of polystyrene microspheres to 20 mmol / L iron phthalocyanine solution and ultrasonically homogenize, stir at room temperature for 12 h, and centrifuge to wash off excess iron phthalocyanine solution;

[0037] Stir 1 g of polystyrene microspheres adsorbed iron phthalocyanine solution with 10 mg / mL defective graphene oxide aqueous solution for 24 h to form a composite structure with polystyrene microspheres as the core and defective graphene oxide as the sh...

Embodiment 3

[0040] The implementation mode is the same as in Example 1, only the first transition metal complex is replaced by tetraammine copper dichloride, and the ammonia synthesis yield can be as high as 18.3 μg·h -1 ·mg -1 cat , the Faraday efficiency is as high as 9.1%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Faraday efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com