Method for preparing abrasion-resistant super-hydrophobic ceramic coating through thermal spraying technology and product

A ceramic coating and super-hydrophobic technology, applied in the coating, metal material coating process, fusion spraying, etc., can solve the complex process, difficult to achieve large-area super-hydrophobic surface preparation, and industrial application, etc., to achieve Good wear resistance, good self-cleaning property and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

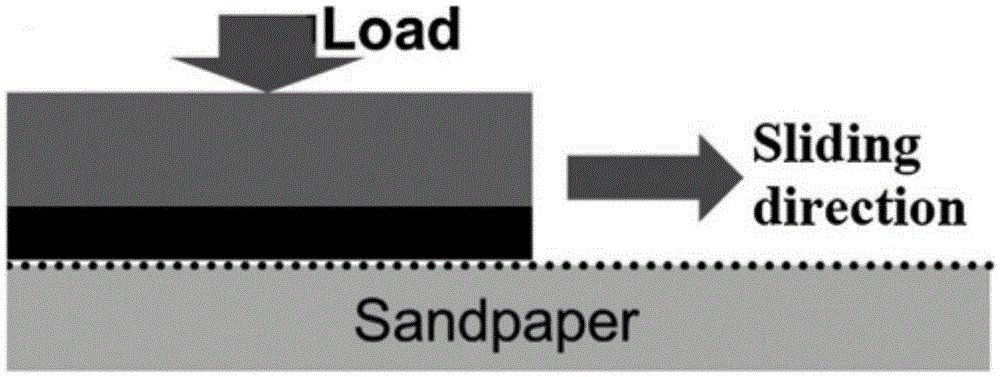

[0034] In this embodiment, 316 stainless steel with a thickness of about 2mm is taken as the substrate, and the specific preparation method of the wear-resistant superhydrophobic coating is as follows:

[0035] (1) Clean the substrate with acetone, hydrochloric acid, and deionized water in sequence, and use 60-mesh brown corundum sand to roughen the surface of the substrate. The air pressure used for sandblasting is 0.5Mpa, and the blasting time is 10 seconds. The number of sand shot is 100 mesh to increase the surface roughness of the substrate and improve the bonding strength of the coating;

[0036] (2) Using the method of plasma spraying, with TiO 2 Powder (average particle size is 100μm) is used as the spraying material, and the spraying parameters for controlling plasma spraying are: arc voltage 40V, arc current 300A, main air flow 40L / min, auxiliary air flow 12L / min, powder feeding speed 50g / min, spraying distance 150mm;,

[0037] (3) Utilize the liquid material flame...

Embodiment 2

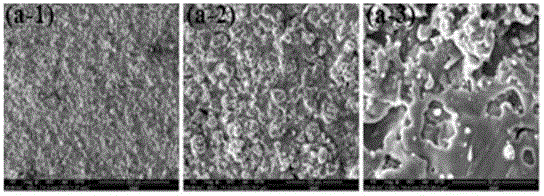

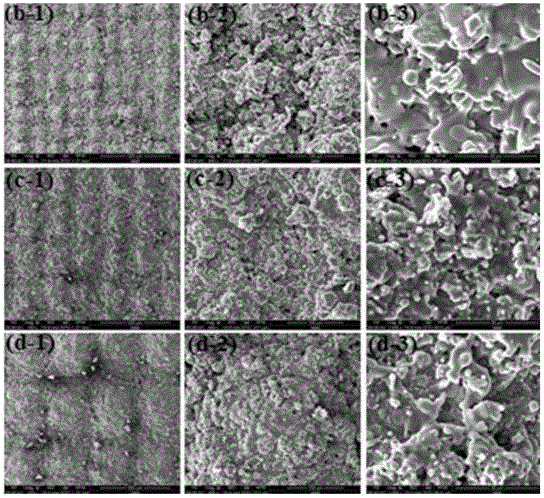

[0043] In this example, in order to study the microscopic characteristics of the coating, different controllable micropattern structures were prepared based on 316 stainless steel in this example. The specific operations are as follows:

[0044] (1) Clean the substrate with acetone, hydrochloric acid, deionized water, etc. in sequence, and use 60-mesh brown corundum sand to roughen the surface of the substrate. The air pressure used for sandblasting is 0.6MPa to increase the surface roughness of the substrate. Meet the roughness requirements of spraying;

[0045] (2) In order to realize the micropatterning of the ceramic coating, 200 mesh, 120 mesh, and 80 mesh stainless steel mesh were used as the spraying substrate in the plasma spraying process;

[0046] (3) Using the method of plasma spraying, with TiO 2Powder (average particle size is 100μm) is used as spraying material, and the spraying parameters for controlling plasma spraying are: arc voltage 40V, arc current 300A, m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com