Preparation method for ionic-liquid-modified carbon quantum dot

A technology of carbon quantum dots and ionic liquids, which is applied in the field of preparation of ionic liquid-modified carbon quantum dots, can solve the problems of difficulty in regulating the function of carbon quantum dots, lack of preparation methods, etc., achieve adjustable dispersion and optical properties, and improve separation efficiency , The effect of high fluorescence quantum yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Disperse 1 gram of citric acid and 3.67 grams of 1-(3-aminopropyl)-3-methylimidazolium bromide in 20 ml of ultrapure water, remove the ultrapure water by rotary evaporation at 60°C to obtain a gel, and then argon Under protection, the jelly was stirred and refluxed at 240°C for 1 hour. After cooling, 30 ml of ultrapure water was added and the dispersion was placed in a dialysis bag with a molecular weight cut-off of 1000 for dialysis for 2 to 3 days. Fluoresces under light (eg figure 1 shown), indicating that carbon quantum dots were generated.

Embodiment 2

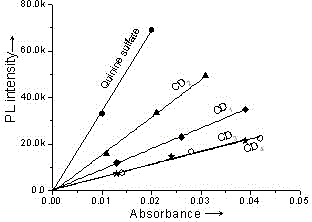

[0038] On the basis of Example 1, the pyrolysis temperature was increased to 260°C, and other conditions remained unchanged, and the dialysate was dried to obtain imidazole-based ionic liquid-modified, anion-Br - carbon quantum dots with a yield of 2.03% and an average particle size of 1.1nm (such as figure 2 shown), Φ=13.9% (as image 3 shown).

Embodiment 3

[0040] On the basis of Example 2, the stirring and reflux time was increased to 2 hours, and the other conditions were unchanged, and the imidazole ionic liquid was modified, and the anion was Br - carbon quantum dots with a yield of 10.3% and an average particle size of 1.1nm (such as Figure 4 shown), Φ=25.1% (as image 3 shown).

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com