PN junction dyeing method

An all-round, sample technology, applied in electrical components, circuits, semiconductor/solid-state device testing/measurement, etc., can solve the problem of poor junction analysis in the guard ring area, indistinguishable PN junctions in the guard ring area, and no staining. The effect of knot effect and other issues can be achieved to achieve the effect of obvious effect and clear appearance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The PN knot dyeing method of the present invention comprises the following steps:

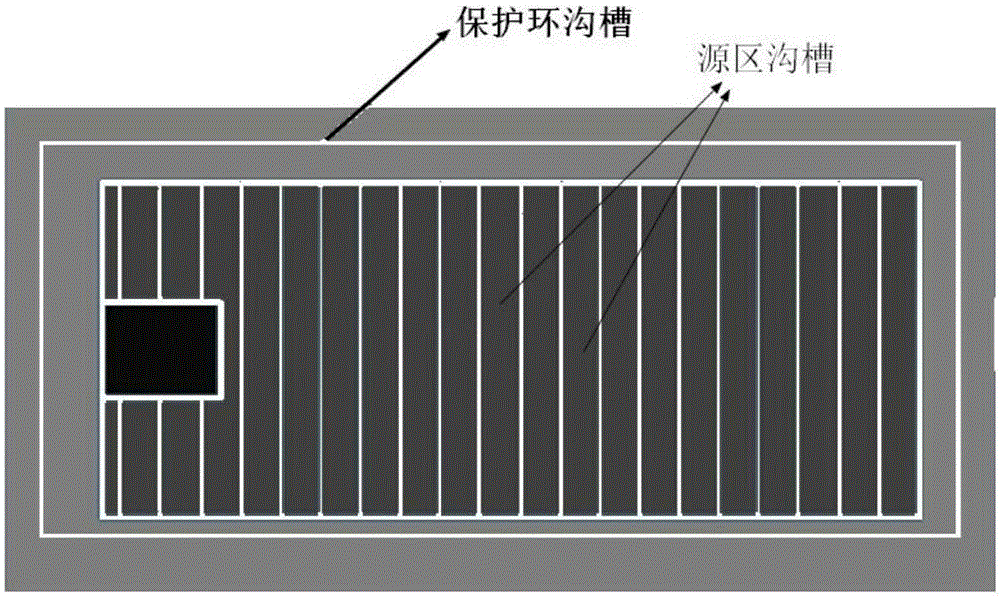

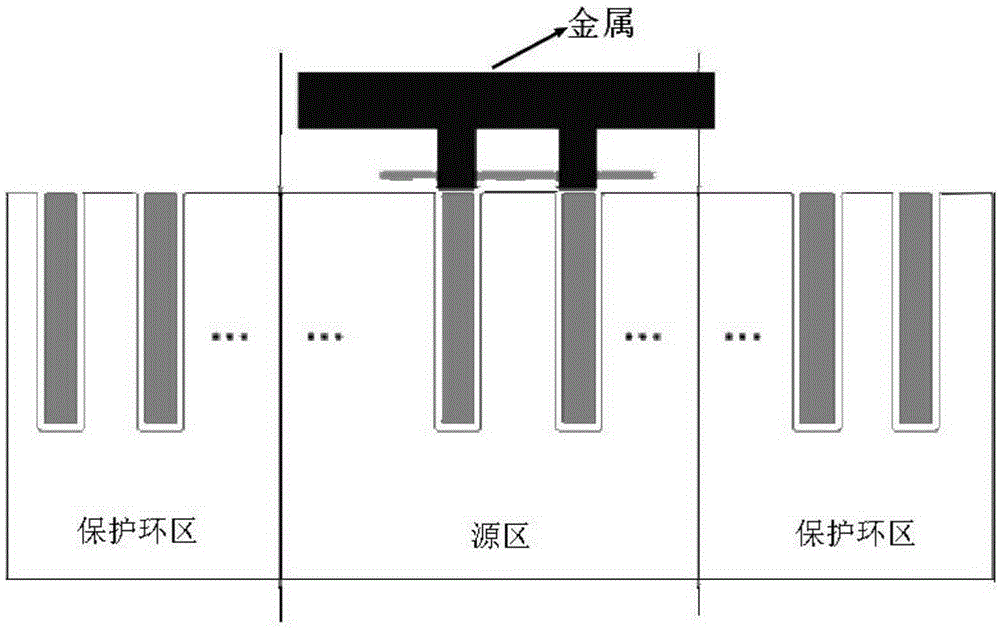

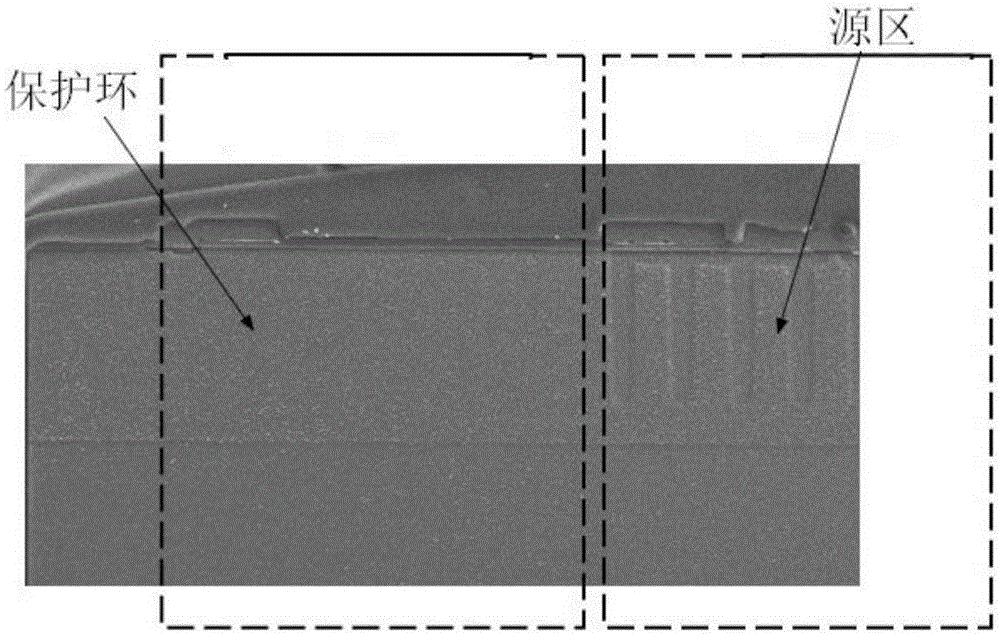

[0030] Step 1: After the surface of the sample to be analyzed is protected, the cross section of the groove is ground, and the protective rings at both ends are ground, and the protective rings are ground at both ends until the groove in the source area is completely exposed. Grinding leaves only parallel grooves on the sample. The trenches include guard ring trenches parallel to each other and source trenches, and the guard rings perpendicular to the source trenches are ground away so that the cross-section of the source trenches is fully exposed. Such as Figure 5 shown. This step will affect the effect of the subsequent gold plating layer on dyeing.

[0031] In the second step, the protective ring area of the ground sample is protected in all directions, and the surface and the back of the unprotected area are gold-plated with a gold plating machine. For example, use the HITACHIE...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com