Transistor forming method

A technology of transistors and dummy gates, which is applied in the field of semiconductor manufacturing, can solve the problems of reduced device density, difficulty in controlling the process of high-K metal gate transistors, and unstable performance of high-K metal gate transistors, etc., and achieves the effect of reducing the difficulty of the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] As mentioned in the background art, with the shrinking of semiconductor process nodes, the process difficulty of forming high-k metal gate transistors increases, and the formed high-k metal gate transistors have poor performance.

[0035] The forming process of the high-K metal gate transistor is a gate last (GateLast) process, Figure 1 to Figure 4 It is a schematic cross-sectional structure diagram of the formation process of a high-K metal gate transistor according to an embodiment of the present invention.

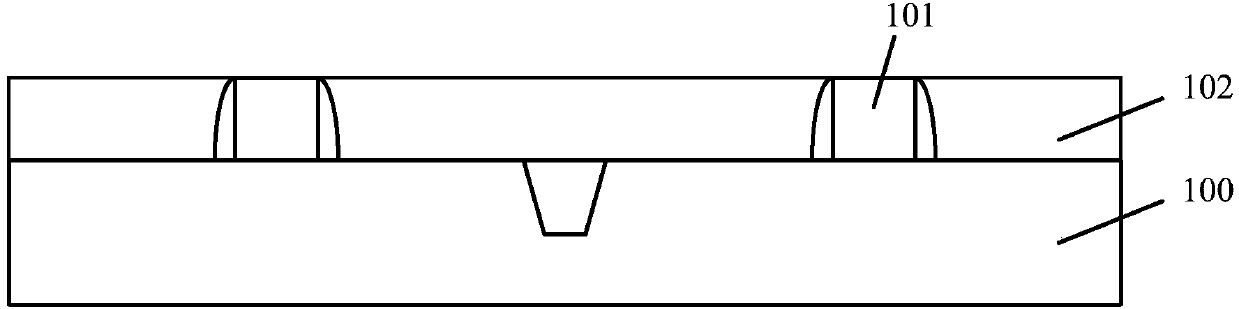

[0036] Please refer to figure 1 A substrate 100 is provided, the surface of the substrate 100 has a dummy gate layer 101, the material of the dummy gate layer 101 is polysilicon, and the dummy gate layer 101 occupies a space and a position for a subsequently formed metal gate.

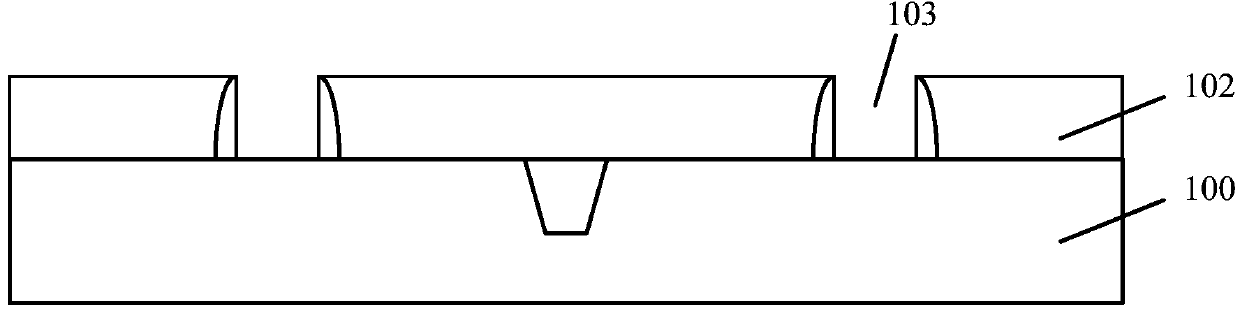

[0037] Please refer to figure 2 , forming a dielectric layer 102 on the surface of the substrate 100 , the dielectric layer 102 covers the sidewall of the dummy gate layer 101 , and t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com