Metal mold low-pressure casting die for box body on cast aluminum gearbox of high-speed train

A high-speed train and low-pressure casting technology, which is applied in the field of cast aluminum gearbox casting, can solve problems such as waste of resources, low productivity, and high labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

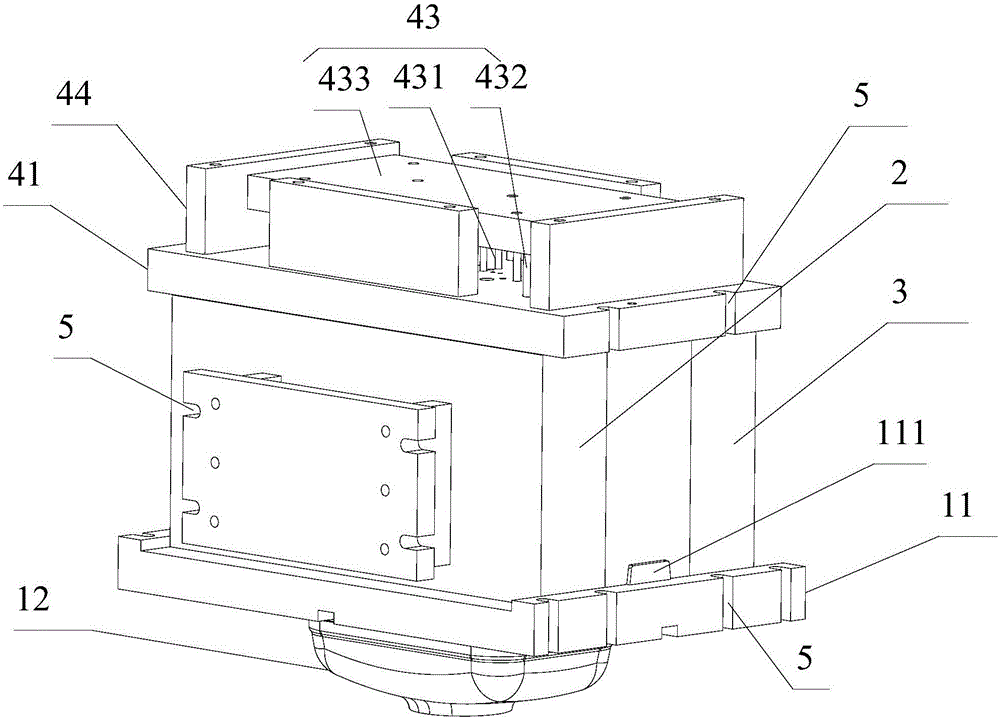

[0031] refer to figure 1 , the present invention proposes a high-speed train cast aluminum gearbox upper box metal type low-pressure casting mold, including a lower mold, an upper mold, a first slider 2, a second slider 3, a lower mold, an upper mold, and a first slider 2. A casting cavity is formed between the second sliders 3 .

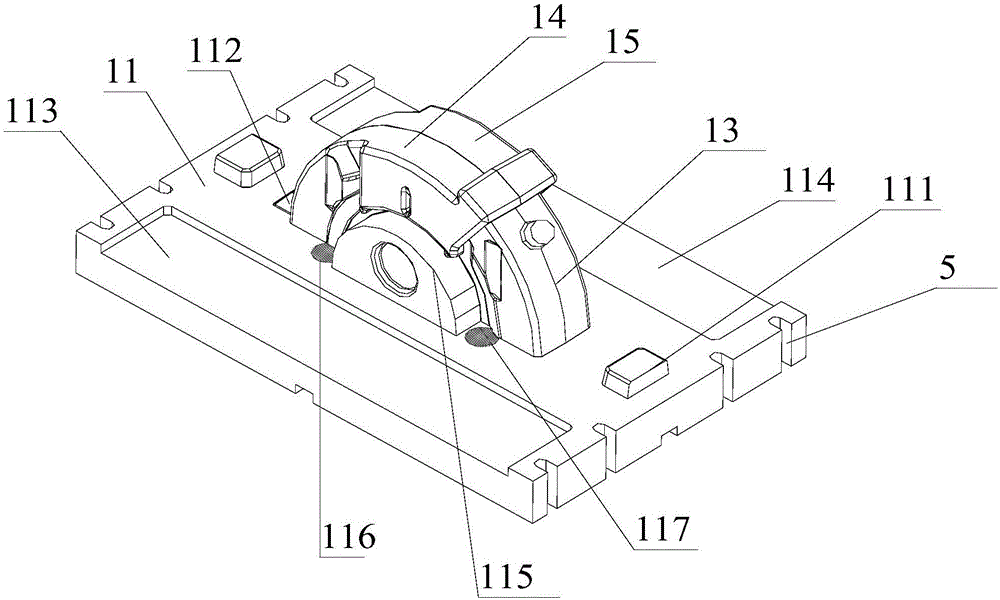

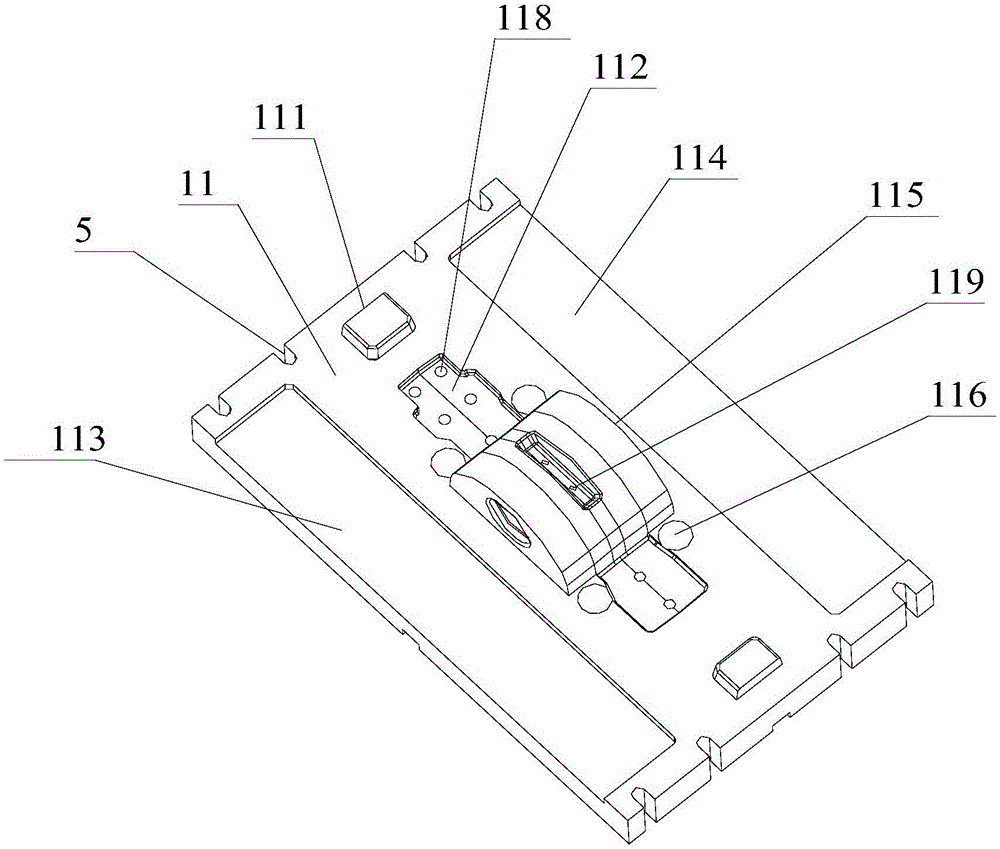

[0032] like figure 2 , image 3 , Figure 11 , Figure 8 As shown, the lower mold in this embodiment includes a lower mold base 11 and a sand core, and one side of the lower mold base 11 is provided with a riser sprue basin 12, and a splitter plate 16 is arranged in the lifter mouth basin 12; the lower mold base 11 is far away from One side of the rising liquid sprue basin 12 is provided with a sand core positioning groove 112, a first slider limiting groove 113 and a second slider limiting groove 114 symmetrically arranged on both sides of the sand core positioning groove 112, and the sand core positioning groove 112 Two upper mold limit bloc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com