Photoresist cleaning composition

A technology for cleaning composition and photoresist, applied in the direction of photosensitive material processing, etc., can solve the problems of chip corrosion and damage, frequent replacement of cleaning solution, inability to completely remove photoresist, etc., and achieve the effect of avoiding interference and strong cleaning ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

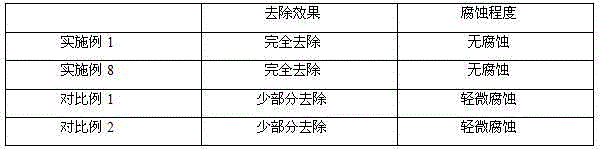

Examples

Embodiment 1

[0014] The photoresist cleaning composition comprises the following components by weight: 1% methyl benzyl alcohol, 0.3% polyoxypropylene triol, 5% nonyl polyoxyethylene ether, 2.4% methyl p-aminobenzoate, and Tea phenol 0.6%, JFC-21%, N-N dimethylformamide 10% and ethylene glycol monomethyl ether 79.7%.

Embodiment 2

[0016] The photoresist cleaning composition comprises the following components in parts by weight: dimethyl benzyl alcohol 2%, polyoxypropylene triol 0.1%, nonyl polyoxyethylene ether 6%, methyl p-aminobenzoate 2.4%, Catechol 0.6%, JFC-21%, N-N dimethylformamide 15% and ethylene glycol monomethyl ether 72.9%.

Embodiment 3

[0018] The photoresist cleaning composition comprises the following components by weight: 1.5% dimethyl benzyl alcohol, 0.2% polyoxypropylene triol, 6% nonyl polyoxyethylene ether, 2% methyl p-aminobenzoate, Catechol 1%, JFC-21%, N-N dimethylformamide 18% and ethylene glycol monomethyl ether 70.3%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com