Coating device for solar heat absorbing film

A coating device and heat-absorbing film technology, applied in sputtering coating, ion implantation coating, vacuum evaporation coating, etc., can solve the problem of high product processing cost, high equipment cost, low single-point arc target ionization rate, etc. problems, to reduce product processing costs, reduce equipment manufacturing costs, and improve market competitiveness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

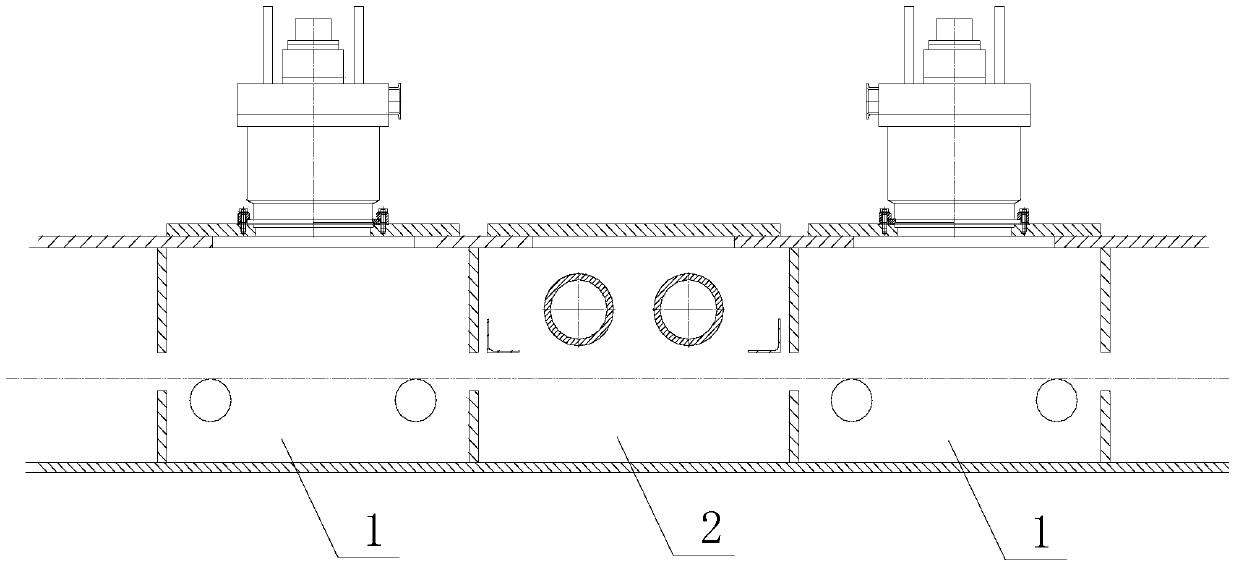

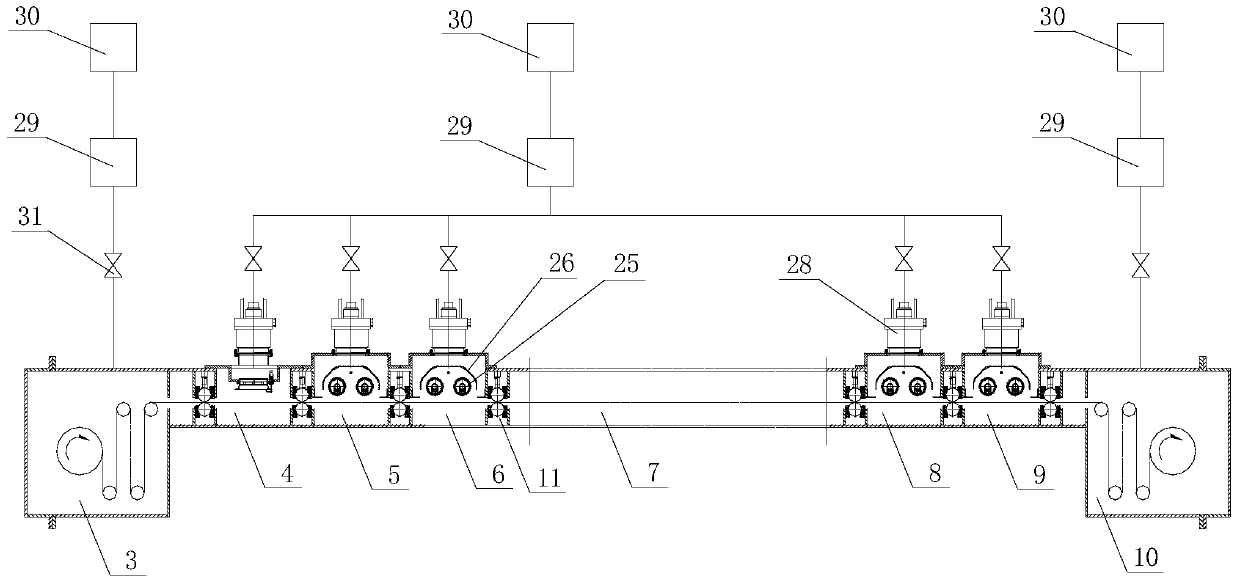

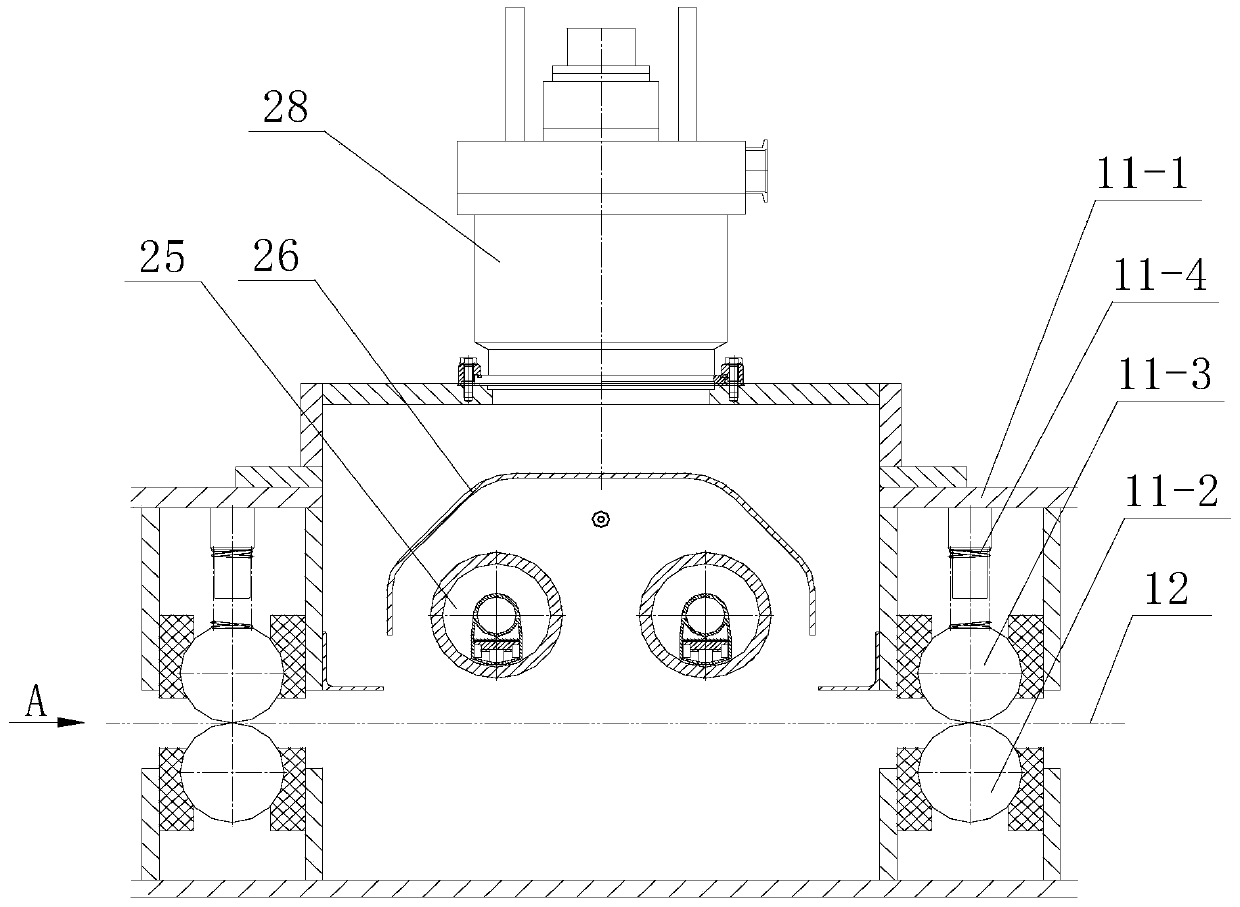

[0033] A coating device for a solar heat absorbing film in this embodiment includes a plurality of vacuum chambers connected in sequence, and the plurality of vacuum chambers include a feed chamber, an ion treatment chamber, a coating chamber and a discharge chamber, such as figure 2 As shown, the vacuum chamber also includes a transition chamber, and there are four coating chambers, which are respectively the first coating chamber, the second coating chamber, the third coating chamber and the fourth coating chamber; Material chamber 3 , ion treatment chamber 4 , first coating chamber 5 , second coating chamber 6 , transition chamber 7 , third coating chamber 8 , fourth coating chamber 9 and discharge chamber 10 . A gas isolation space is provided at the junction of any two adjacent vacuum chambers, and a gas isolation mechanism 11 is arranged in the gas isolation space. like image 3 or Figure 4 As shown, the gas isolation mechanism includes a top plate 11-1, a transmission...

Embodiment 2

[0039] A kind of coating device that present embodiment is used for solar heat absorbing film, compared with embodiment 1, its difference is: in each vacuum chamber, there are two groups of intermediate frequency magnetron targets in the same coating chamber, as Image 6 or Figure 7 As shown, each intermediate frequency magnetron target includes a target tube 25-1, a target core 25-2 and a second drive mechanism 25-3, one end of the target core is connected to the second drive mechanism, the target core is located inside the target tube, and on the target core Five second magnets 25-4 are provided, and the five second magnets are fan-shaped distributed on the periphery of the target core, and the five second magnets form two annular sputtering tracks in the space between the target tube and the target core. The setting of the five-way second magnet makes two annular sputtering raceways formed in the space between the target tube and the target core (such as Figure 8 As show...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com