Super-cutting-resistant rubber material for screen plate of vibrating screen and preparation method of super-cutting-resistant rubber material

A rubber compound and cutting-resistant technology, which is applied in the field of preparation of super-cut-resistant rubber compound, can solve the problems of short service life, high noise, and short service life of metal sieve plates, so as to improve the cutting resistance and use The effect of life and good cutting resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

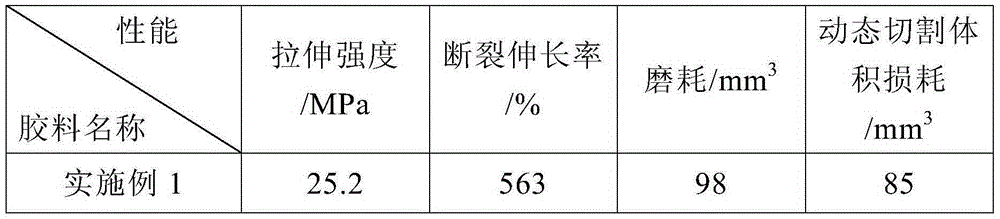

Examples

Embodiment 1

[0022] Prepare the raw materials for the super-cut-resistant rubber compound used for preparing the vibrating screen sieve plate, specifically include: 10 kilograms of non-oil-extended styrene-butadiene rubber, and the mass percentage of its combined styrene in the non-oil-extended styrene-butadiene rubber is 22.5 % to 24.5%, the reinforcing filler consisting of 800 grams of white carbon black, 900 grams of short glass fibers and 800 grams of carbon black N115 totals 2500 grams, the length of the short glass fibers is 2 to 2.5mm, and the length of the short glass fibers The diameter is 13.5~14μm, the sulfur is 50 grams, and the vulcanization accelerator consisting of 30 grams of sulfenamide accelerator CZ, 20 grams of sulfenamide accelerator NS and 30 grams of thiazole accelerator DM is 80 grams in total. , a total of 300 grams of vulcanization activator consisting of 100 grams of zinc oxide and 200 grams of stearic acid, a total of 200 grams of silane coupling agent Si-69, 100...

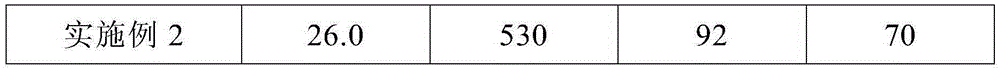

Embodiment 2

[0032] Prepare the raw materials for the super cutting-resistant rubber compound used for preparing the vibrating screen sieve plate, specifically include: 10 kilograms of unextended styrene-butadiene rubber, and the mass percentage of its bound styrene in the unextended oil-extended styrene-butadiene rubber is 22.5 %~24.5%, 6.5 kg of white carbon black, 300 g of sulfur, 500 g of sulfenamide accelerator CZ, 1.2 kg of zinc oxide, 1.2 kg of silane coupling agent Si-69, 500 g of boronyl Cobalt, 2 kg of aromatic oil, 800 g of anti-aging agent RD.

[0033] A kind of preparation method of the super-cut-resistant rubber compound that is used for vibrating screen sieve plate comprises the following steps:

[0034] a. Take 10 kg of non-oil-extended styrene-butadiene rubber, and the mass percentage of bound styrene in the non-oil-extended styrene-butadiene rubber is 22.5% to 24.5%, and put 10 kg of non-oil-extended styrene-butadiene rubber into the banburying Mix in the mixer for 1 to ...

Embodiment 3

[0043]Prepare the raw materials for the super-cut-resistant rubber compound used for preparing the vibrating screen sieve plate, specifically include: 10 kilograms of non-oil-extended styrene-butadiene rubber, and the mass percentage of its combined styrene in the non-oil-extended styrene-butadiene rubber is 22.5 % to 24.5%, a total of 4.5 kg of reinforcing filler consisting of 2 kg of short glass fibers and 2.5 kg of white carbon black, the length of the short glass fibers is 2 to 2.5 mm, and the diameter of the short glass fibers is 13.5 to 14 μm. 200 grams of sulfur, a total of 300 grams of vulcanization accelerator consisting of 100 grams of sulfenamide accelerator CZ and 200 grams of thiazole accelerator DM, 700 grams of stearic acid, 700 grams of silane coupling agent Si -69, 300 grams of cobalt boroacylate, 1.2 kg of coumarone, 400 grams of anti-aging agent consisting of 200 grams of anti-aging agent MB and 200 grams of anti-aging agent BLE.

[0044] A kind of preparati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com