Preparation method for high-purity glabridin monomer

A high-purity technology of glabridin, which is applied in organic chemistry and other fields, can solve the problems of low-purity glabridin, low content, and long separation time, and achieve the effects of rapid preparation, separation, mild separation environment, and short separation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Take 3kg of licorice, crush it, and put it at 40~80 0 Under the temperature of C, within 1~2 hours, reflux extraction with 70% ethanol for 3 times, each time for 1h, the extracts were combined and then concentrated under reduced pressure to obtain 162g of extract, which was enriched with licorice root by reverse phase C18 column chromatography 4L of 30%, 50%, 70% and 95% ethanol / water were used for elution, and the 70% ethanol eluate was collected, detected by HPLC, and concentrated to dryness under reduced pressure to obtain 28g of crude glabridin.

[0023] Preparation of high-purity glabridin monomer:

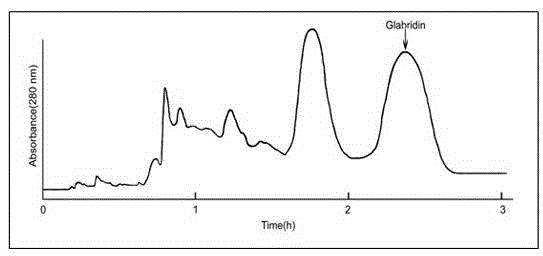

[0024] Using a preparative high-speed countercurrent chromatograph, the separation solvent is selected from petroleum ether, ethyl acetate, ethanol and water to separate and prepare high-purity glabridin monomer from the crude product of glabridin; first, the above-mentioned Configure 2L of separation solvent in a separatory funnel, shake well, let stand for 12 hours,...

Embodiment 2

[0027] Take 3kg of licorice, crush it, and put it at 40~80 0 Under the temperature of C, within 1 to 2 hours, reflux extraction with 90% ethanol for 3 times (1 hour each time), the extracts were combined and concentrated under reduced pressure to obtain 171g of extract; the extract was enriched with glabridin by reverse phase C18 column chromatography , sequentially eluted with 4 L of 30%, 50%, 70% and 95% ethanol / water, collected 70% ethanol eluate, detected by HPLC, concentrated under reduced pressure to dryness to obtain 28 g of crude glabridin.

[0028] Preparation of high-purity glabridin monomer:

[0029]High-purity glabridin monomer was separated from crude glabridin by using a preparative high-speed countercurrent chromatograph, and the separation solvent was n-hexane, ethyl acetate, ethanol and water. First, configure 2L of the above solvent system in a separatory funnel with a volume ratio of 5:5:5.5:4.5, shake it up and let it stand for 12 hours to separate layers....

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com