Emulsion breaker for polymer and surface active agent crude oil and preparation method thereof

A technology of surfactant and demulsifier, which is applied in the field of demulsifier and its preparation for crude oil containing polymers and surfactants. It can solve the problems of high content of suspended solids, poor water quality of extracted sewage, and poor water quality of sewage, and achieve strong The effect of surface activity and good hydrophilic and lipophilic properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

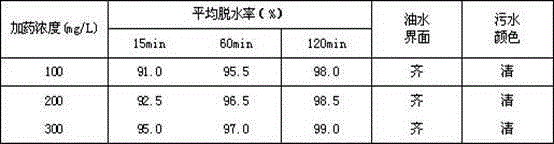

Examples

Embodiment 1

[0032] A demulsifier for polymer and surfactant crude oil, the demulsifier is composed of the following parts by weight:

[0033] Ethylene oxide: 40-43.5 parts;

[0034] Ethylene oxide-propylene oxide block copolyether: 20 to 30 parts;

[0035] Alkylbenzenesulfonate: 25-30 parts;

[0036] Mutual solvent: 2.5 to 3.0 parts;

[0037] Ethylene glycol: 10-15 parts;

[0038] Water: 9-12 parts.

[0039] The preparation method for the demulsifier of polymer and surfactant crude oil, comprises the following steps:

[0040] 1), the preparation of intermediates:

[0041] Add 0.2 to 0.5 parts by weight of catalyst sodium ethylate and 0.5 to 0.8 parts by weight of starter pentaethylenehexamine in a stainless steel high-pressure reaction kettle, and vacuumize and fill with nitrogen three times at 20 to 30°C to replace the Air, heating up to 120°C, feeding 98.5 to 100.5 parts by weight of propylene oxide, and controlling the reaction pressure to 0.2 to 0.4 MPa, and reducing the pressur...

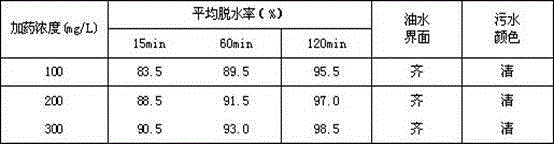

Embodiment 2

[0052] This embodiment specifically provides a method for preparing a demulsifier for polymer and surfactant crude oil, specifically according to the following steps:

[0053] 1), the preparation of intermediates:

[0054] Add 0.2 parts by weight of catalyst sodium ethylate and 0.5 parts by weight of initiator pentaethylenehexamine in a stainless steel high-pressure reactor, vacuumize and fill with nitrogen three times at 20°C to replace the air in the kettle, and heat up to 120°C , feed 98.5 parts by weight of propylene oxide, and control the reaction pressure to 0.2MPa, after 2 hours, reduce the pressure until the pressure does not change anymore, to obtain the intermediate.

[0055] 2), Preparation of ethylene oxide-propylene oxide block copolyether:

[0056] Add 0.3 parts by weight of catalyst sodium ethylate and 20 parts by weight of the intermediate prepared by step 1) in the stainless steel autoclave, vacuumize and fill with nitrogen three times, feed 78.5 parts by weigh...

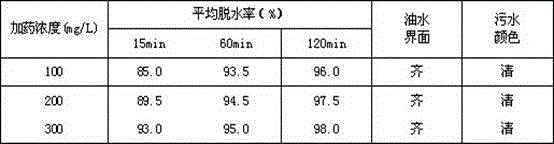

Embodiment 3

[0064] This embodiment specifically provides a method for preparing a demulsifier for polymer and surfactant crude oil, specifically according to the following steps:

[0065] 1), the preparation of intermediates:

[0066] Add 0.3 parts by weight of catalyst sodium ethylate and 0.6 parts by weight of starter pentaethylenehexamine in a stainless steel high-pressure reactor, vacuumize and fill with nitrogen three times at 25°C to replace the air in the kettle, and heat up to 120°C , feed 99.5 parts by weight of propylene oxide, and control the reaction pressure to 0.3MPa, after 2 hours, reduce the pressure until the pressure no longer changes, and obtain the intermediate.

[0067] 2), Preparation of ethylene oxide-propylene oxide block copolyether:

[0068] Add 0.4 parts by weight of catalyst sodium ethylate and 22 parts by weight of the intermediate prepared by step 1) in the stainless steel autoclave, vacuumize and fill with nitrogen three times, feed 80 parts by weight of et...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com