A kind of grinding method of boron carbide air bearing

A technology of air bearings and boron carbide, which is applied in the direction of grinding workpiece supports, grinding/polishing equipment, machine tools suitable for grinding workpiece planes, etc., and can solve the problems affecting the processing accuracy and efficiency of parts, small cutting amount, and processing efficiency Low-level problems, to achieve the effect of improving shape and position accuracy and processing efficiency, optimizing grinding parameters, and convenient processing operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The existing boron carbide air bearing adopts the processing accuracy that can be achieved by the existing grinding process: the outer cylindricity of the bearing is 0.002mm, the cylindricity of the inner hole is 0.005mm, the perpendicularity between the two ends of the surface and the inner hole is 0.002mm, and the inner and outer circles are 0.002mm. The coaxiality is Φ0.002mm, and the surface roughness is Ra0.2μm. However, the above-mentioned accuracy can no longer meet the current application requirements.

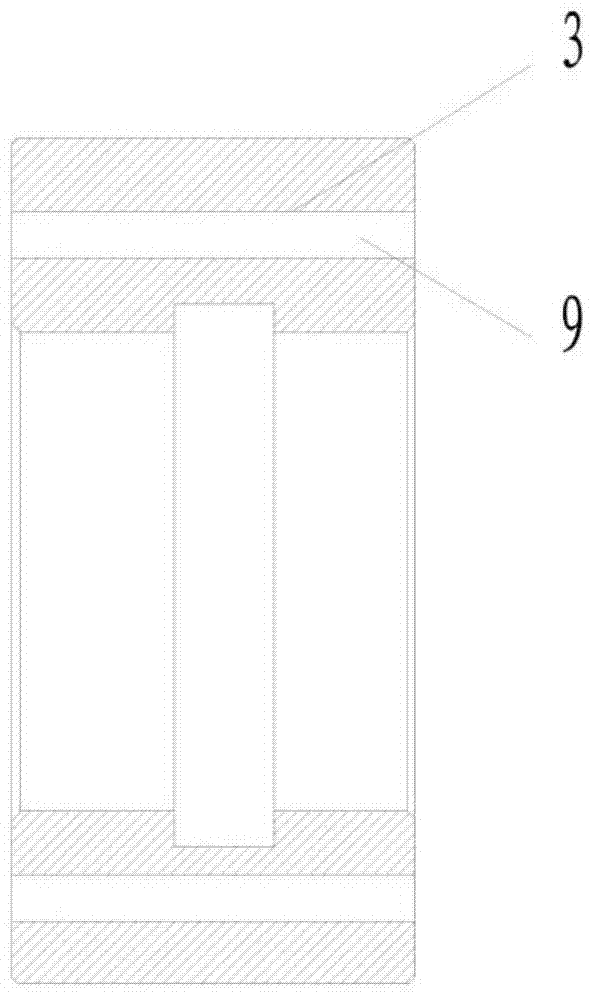

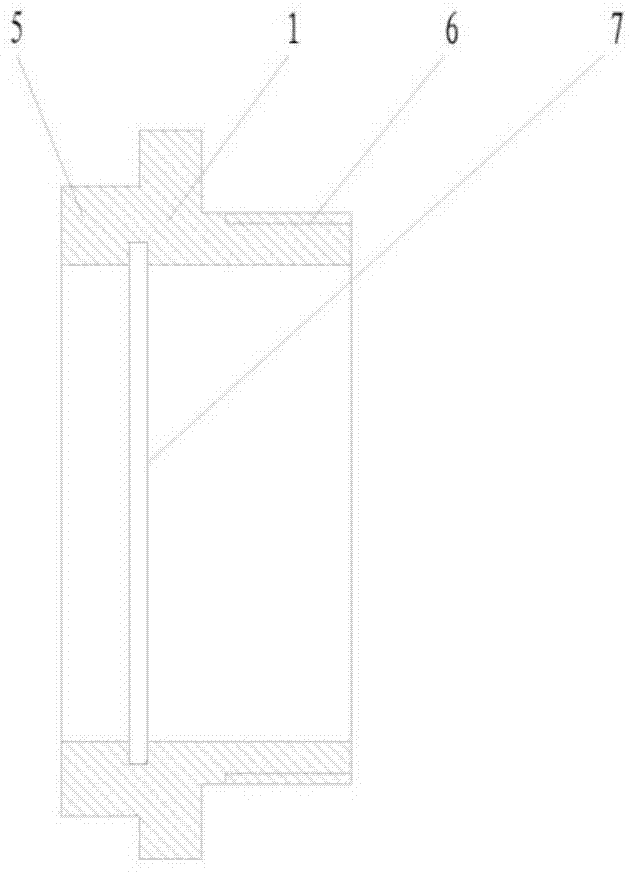

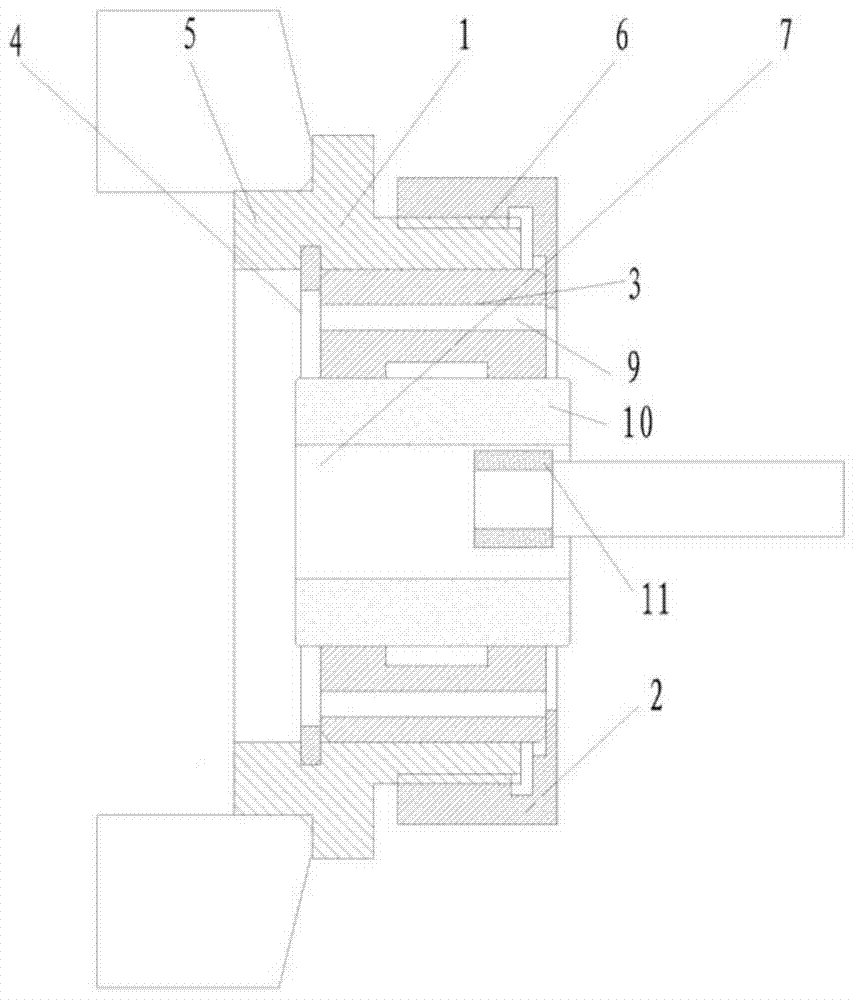

[0039] The invention proposes a grinding device for boron carbide air bearings, such as figure 1 and figure 2 As shown, a grinding device for a boron carbide air bearing includes a positioning seat 1, a compression nut 2, a positioning ring 3 and a retaining ring 4; the positioning seat 1 is a cylindrical structure; the outer wall of the positioning seat 1 is provided with a The limit protrusion 5 clamped on the grinding machine chuck and the external thread ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com