Electronic spray sterilization and protein peptide bond breakage equipment

A protein and electrospray technology, applied in food science, food preservation, application, etc., can solve the problems of unsuitable treatment, small diameter of the outlet end of the hollow capillary launch needle cone, etc., and achieve the effect of complete sterilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

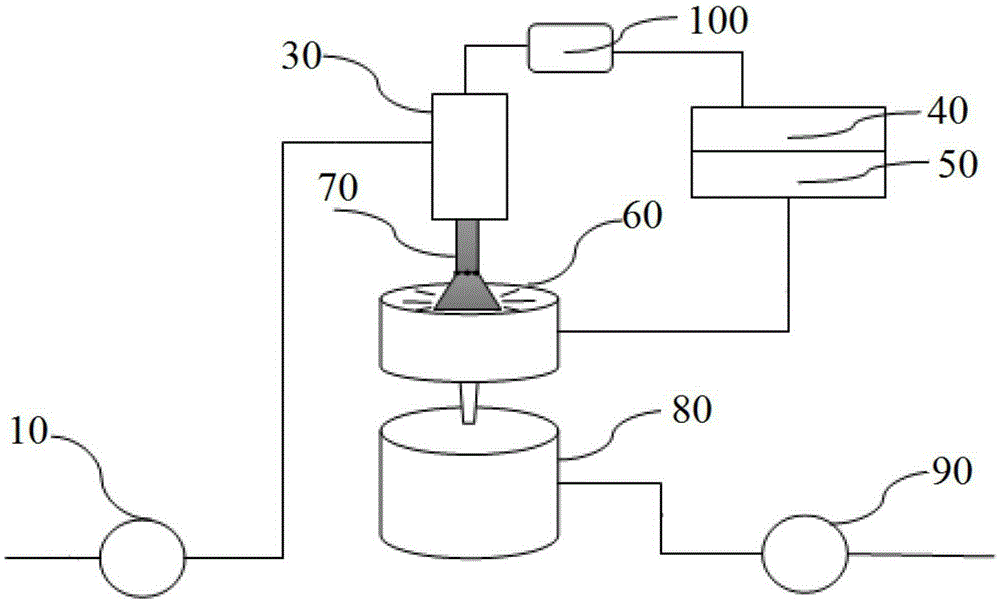

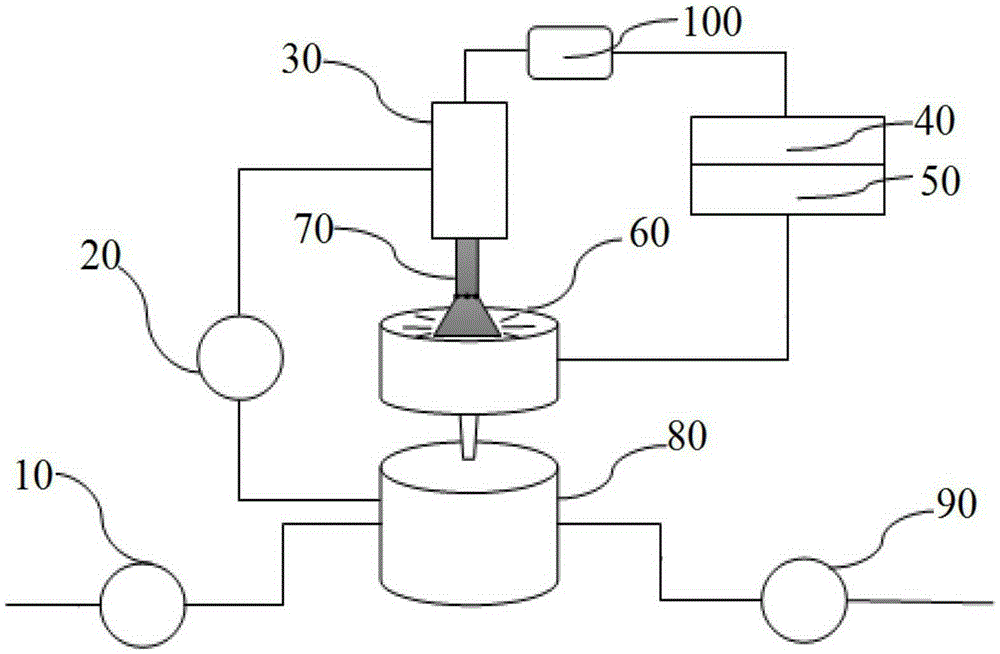

[0037] Embodiment 1: as figure 1 , Figure 5 , Figure 8 As shown, the equipment for electrospray sterilization and protein peptide bond breaking described in Example 1 includes a feed delivery pump 10, a voltage device 40, and an atomization device 30, and the positive pole or negative pole of the voltage device 40 is connected to the electrode container through a cable 60. The other pole of the voltage device 40 is connected to the atomizing device 30 through the isolation transformer 100. The atomizing device 30 is provided with a liquid inlet and a liquid outlet. The nozzles are connected, and the emission nozzle is connected to the electrode container 60 made of metal material. The electrode container 60 is connected to the transfer container 80. The inner surface of the transfer container 80 is provided with a metal layer. The transfer container 80 is connected with a grounding wire. The transfer container 80 The discharge delivery pump 90 is connected through a pipeli...

Embodiment 2

[0038] Embodiment 2: as figure 1 , Figure 5 , Figure 8 As shown, the difference between the electrospray sterilization and protein peptide bond breaking equipment described in Embodiment 2 and Embodiment 1 is that the bottom end of the horn body of the horn-type emission nozzle 70 is provided with a plurality of parallel annular knife-shaped port 72.

[0039] The specific sterilization process of a kind of electrospray sterilization and protein peptide bond breaking equipment described in embodiment 1 and embodiment 2 is: the liquid is transported to the ultrasonic atomizer or air motor or electric motor through the feed delivery pump 10, so that The above-mentioned ultrasonic atomizer or air motor or electric motor sends the liquid to the inside of the hollow cylinder of the launching nozzle through the liquid inlet, and then flows out from the small water outlet hole on the side of the cylinder of the launching nozzle and flows down the horn body slope of the launching n...

Embodiment 3

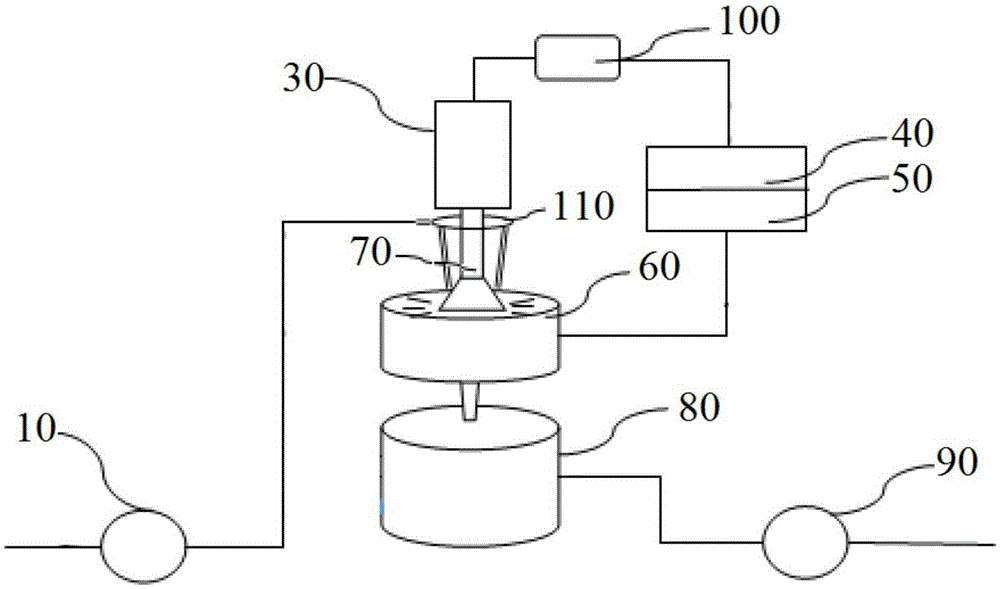

[0040] Embodiment 3: as figure 2 , Figure 5 to Figure 8 As shown, a kind of electrospray sterilization and protein peptide bond breaking equipment described in Example 3 of the present invention includes a feed delivery pump 10, a voltage device 40, and an atomization device 30, and the positive pole or negative pole of the voltage device 40 is connected to the electrode through a cable The container 60 and the other pole of the voltage device 40 are connected to the atomizing device 30 through the isolation transformer 100, and the atomizing device 30 is connected to a spray nozzle made of conductive material, and a multi-tube feeder 110 is sleeved outside the spray nozzle. The multi-tube feeder 110 is provided with an annular conduit 111, and the surface of the multi-tube feeder 110 is provided with 10 water outlet grooves 112 communicating with the annular conduit 111, and the water outlet grooves 112 are evenly distributed along the circumference of the multi-tube feeder...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Voltage value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com