Method for preparing taste-active peptide through fermentation of composite probiotics

A technology of compounding probiotics and probiotics, applied in food preparation, protein food processing, animal protein processing and other directions, can solve problems such as harmful human health, and achieve the effect of promoting weight loss, rich nutrition and short fermentation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

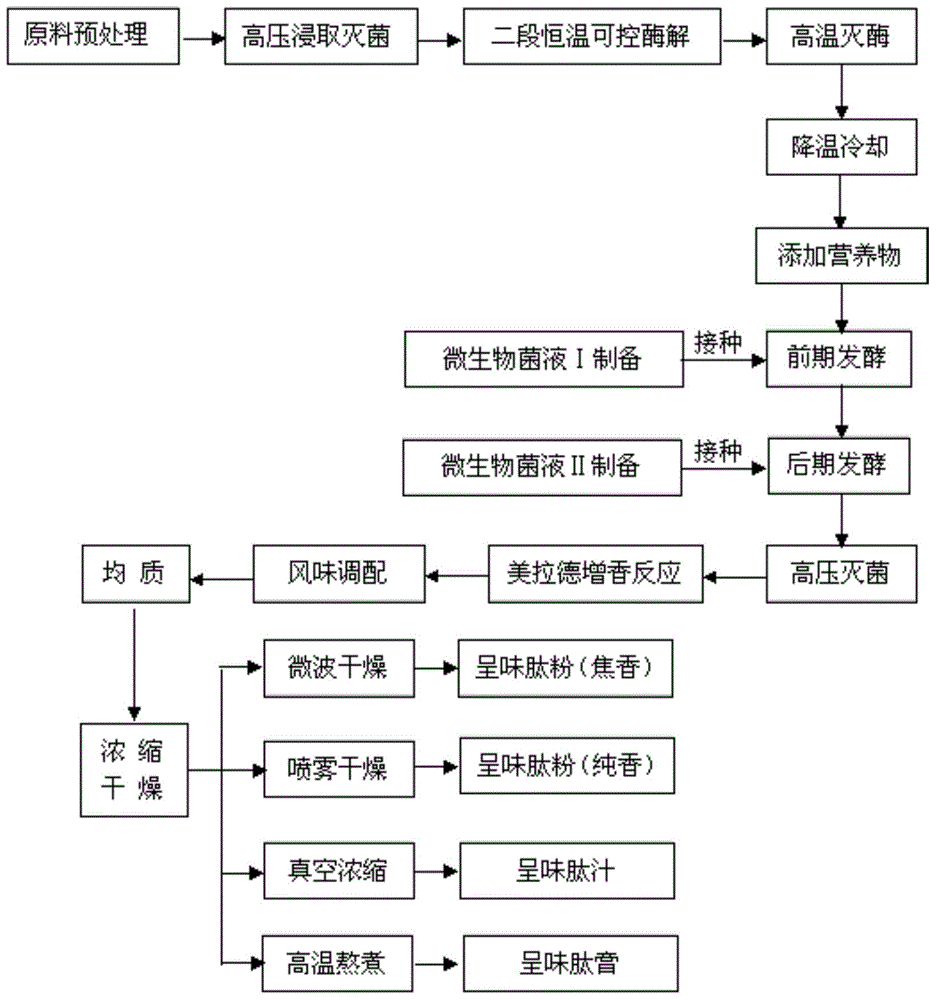

Image

Examples

Embodiment 1

[0040] According to the content of the present invention, the inventor makes seafood peptide, and the steps are as follows:

[0041] (1) raw material pretreatment: the seafood is cleaned and divided, and pure water is added according to a solid-to-liquid ratio of 1:1, soaked and thawed for 1.0 h under low temperature conditions, and then the soaked and thawed raw materials are mashed;

[0042] (2) High-pressure soaking sterilization: Put the treated slurry into the jacketed pot and heat it up to 100°C for about 0.5 hours to sterilize;

[0043] (3) Two-stage constant temperature controllable enzymolysis: cooling down to 50°C, adding compound protease according to 0.4% of the total weight of the raw materials, the compound protease is papain and animal hydrolyzing protease, divided into three times according to 1 / 3 of the total enzyme amount Add, carry out constant temperature directional enzymolysis, time 6.0h, keep uniform stirring during the period; after complex protease enz...

Embodiment 2

[0053] According to the content of the present invention, the inventor makes the wild fungal peptide, and the steps are as follows:

[0054] (1) Raw material pretreatment: wash and divide the wild mushrooms, add pure water according to a solid-to-liquid ratio of 1:5, soak and thaw for 1.0 h under low temperature conditions, and then mash the soaked and thawed raw materials;

[0055] (2) High-pressure soaking sterilization: Put the treated slurry into the jacketed pot and heat up to 100°C for sterilization for about 1.0h;

[0056] (3) Two-stage constant temperature controllable enzymatic hydrolysis: cooling down to 60°C, adding compound protease according to 1.6% of the total weight of raw materials, the compound protease is papain and animal hydrolyzing protease, divided into three times according to 1 / 3 of the total enzyme amount Add, carry out constant temperature directional enzymolysis, time 6.0h, keep uniform stirring during the period; after complex protease enzymolysis,...

Embodiment 3

[0066] According to the content of the present invention, the contriver makes animal bone peptide, and the steps are as follows:

[0067] (1) raw material pretreatment: the chicken skeleton is cleaned and divided, pure water is added according to a solid-to-liquid ratio of 1:2, soaked and thawed for 1.0 h under low temperature conditions, and then the soaked and thawed raw materials are mashed;

[0068] (2) High-pressure soaking sterilization: Put the treated slurry into the jacketed pot and heat it up to 100°C for about 0.8h of sterilization;

[0069] (3) Two-stage constant temperature controllable enzymolysis: cooling down to 55°C, adding compound protease according to 1% of the total weight of raw materials, the compound protease is neutral protease bromelain protease, divided into three times according to 1 / 3 of the total enzyme amount Add, carry out constant temperature directional enzymolysis, time 3h, keep stirring evenly during the period; after compound protease enzym...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com