Turnover type repair method for normal-temperature curing lining and turnover device for turnover type repair method

A technology of normal temperature curing and repair method, which is applied in the direction of pipes/pipe joints/fittings, mechanical equipment, pipe components, etc., which can solve the problem of insufficient height space on the upper part of the inspection well, long time required for preparation work, and inability to erect an overturning tower To achieve the effect of increasing the scope of use, reducing traffic pressure and saving materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

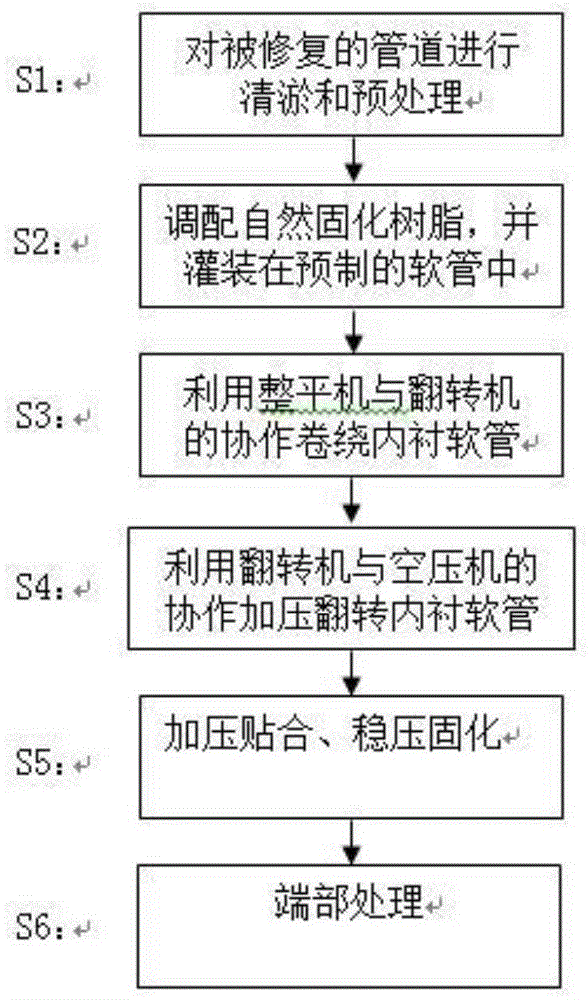

Method used

Image

Examples

Embodiment

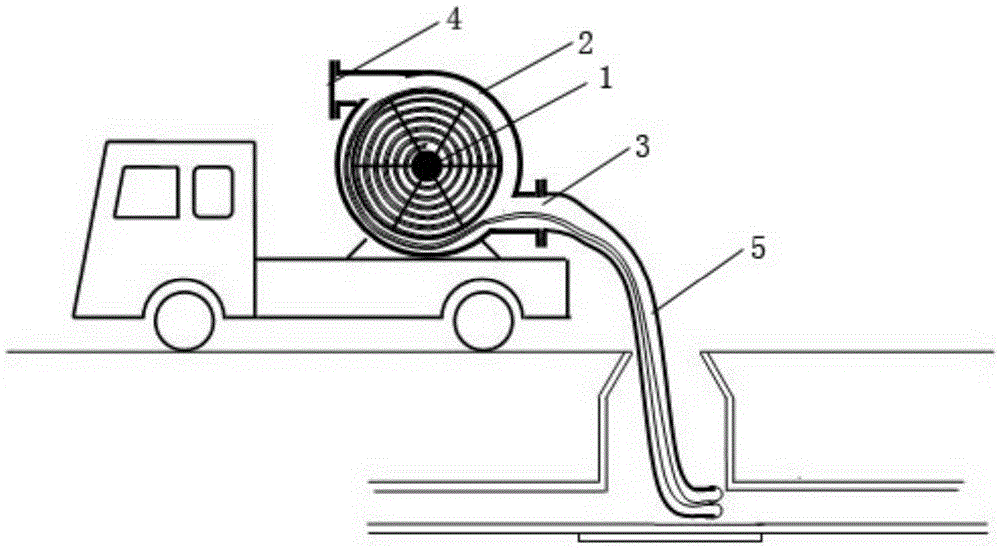

[0078] Park the equipment truck loaded with the turning machine at the wellhead of the pipeline to be repaired, and stop the material transport vehicle in front of the equipment truck in turn, and use the car to set up a dipping, rolling, and leveling platform in front of the feeding port of the turning machine. Calculate the amount of resin and curing agent according to the actual project, then mix and stir the resin and curing agent at a weight ratio of 3:1 to form the required normal temperature curing resin, and pour the resin into the hose. The initial setting time of the normal temperature curing resin used is estimated by adding 1 hour to the actual operation time of the project to ensure that the construction requirements are met. Bind one end of the grout and pass it through the leveling machine, fix it to the inner winding drum of the turning machine, start the turning machine to wind up, and at the same time, roll and level the resin hose through the leveling machine...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com