Electrogalvanizing method based on choline chloride-xylitol deep eutectic solvent

A technology of deep eutectic solvent and choline chloride, which is applied in the field of electroplating and can solve problems such as combustion and explosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

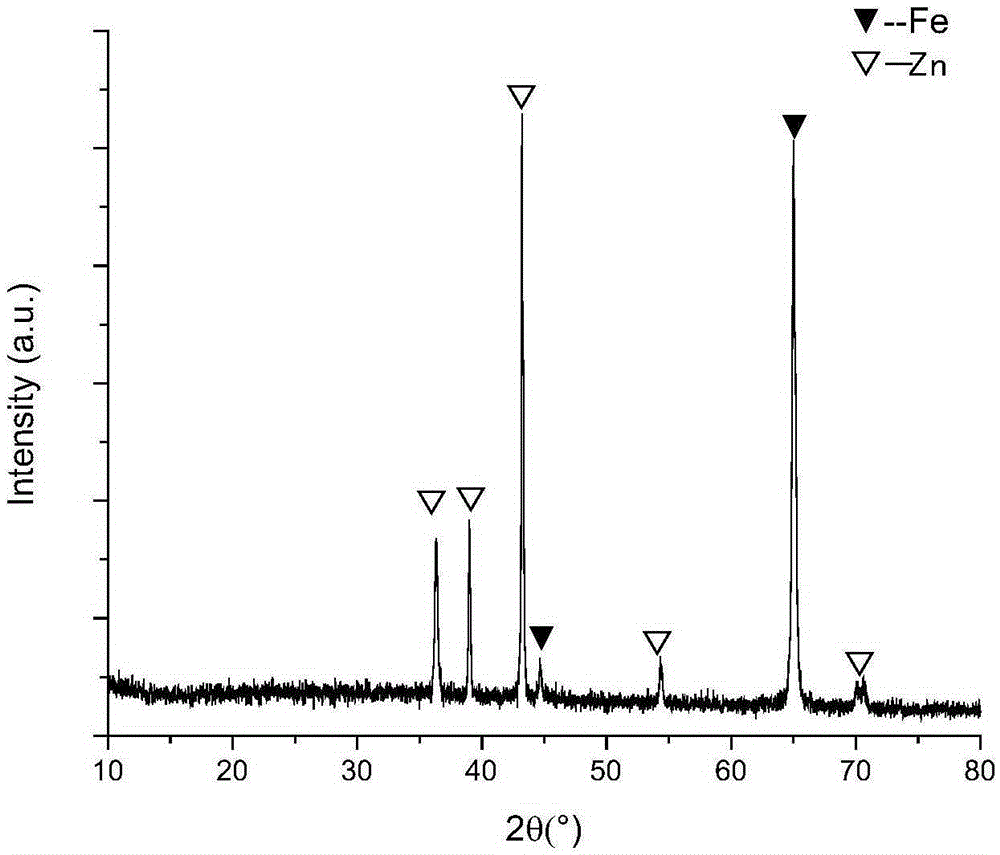

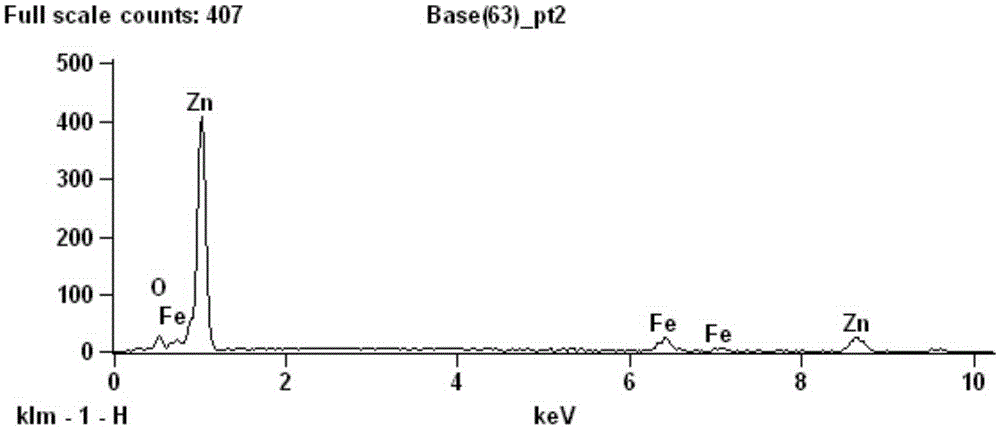

Image

Examples

Embodiment 1

[0029] Firstly, 0.1 mol xylitol, 0.2 mol choline chloride, and 0.3 mol distilled water were respectively weighed and placed in a beaker. The beaker was sealed with plastic wrap, and then stirred at a constant temperature of 50° C. to obtain a transparent eutectic solvent. Then add 0.025 mol of zinc chloride and stir at 50°C to obtain a zinc-containing eutectic solvent;

[0030] The pure zinc plate is used as the anode and the low carbon steel is used as the cathode. It is immersed in a zinc-containing eutectic solvent heated to 50℃ in a water bath for 30 minutes of constant current electroplating. The direct distance between the cathode and the anode is 1cm, and the current density is 2.5mA / cm. 2 ;

[0031] After the electroplating is completed, the low carbon steel is taken out and washed twice with double distilled water, and finally dried in an oven at 60°C.

[0032] The conductivity of the eutectic solvent of choline chloride-xylitol-distilled water at room temperature and 50℃ is...

Embodiment 2

[0035] Firstly, 0.1 mol xylitol, 0.2 mol choline chloride, and 0.3 mol distilled water were respectively weighed and placed in a beaker. The beaker was sealed with plastic wrap, and then stirred at a constant temperature of 50° C. to obtain a transparent eutectic solvent. Then add 0.025 mol of zinc chloride and stir at 50°C to obtain a zinc-containing eutectic solvent;

[0036] Using pure zinc plate as anode and low carbon steel as cathode, immerse it in a zinc-containing eutectic solvent heated to 50℃ in a water bath for 15 minutes constant current electroplating. The direct distance between cathode and anode is 2cm, and the current density is 3mA / cm. 2 ;

[0037] After the electroplating is completed, the low carbon steel is taken out and washed twice with double distilled water, and finally dried in an oven at 60°C.

Embodiment 3

[0039] Firstly, 0.1 mol xylitol, 0.2 mol choline chloride, and 0.3 mol distilled water were respectively weighed and placed in a beaker. The beaker was sealed with plastic wrap, and then stirred at a constant temperature of 50° C. to obtain a transparent eutectic solvent. Then add 0.025 mol of zinc chloride and stir at 50°C to obtain a zinc-containing eutectic solvent;

[0040] The pure zinc plate is used as the anode and the low carbon steel is used as the cathode. The zinc-containing eutectic solvent heated to 60℃ in a water bath is used for 30 minutes constant current electroplating. The direct distance between the cathode and the anode is 1cm, and the current density is 5mA / cm. 2 ;

[0041] After the electroplating is completed, the low carbon steel is taken out and washed twice with double distilled water, and finally dried in an oven at 60°C.

[0042] The conductivity of the choline chloride-xylitol-distilled water eutectic solvent at 60℃ is 6.40ms·cm -1 .

[0043] The conductiv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com