Biotic bone composite material and preparing method thereof

A composite material and biological technology, applied in the field of materials, can solve problems such as deformation and cracking, and achieve high corrosion resistance, good wear resistance and corrosion resistance, and high wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

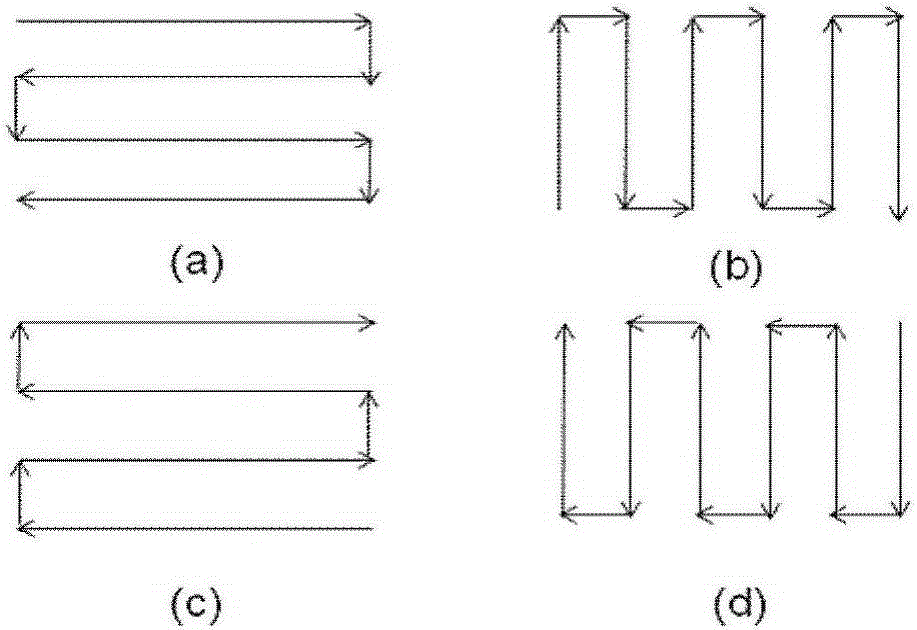

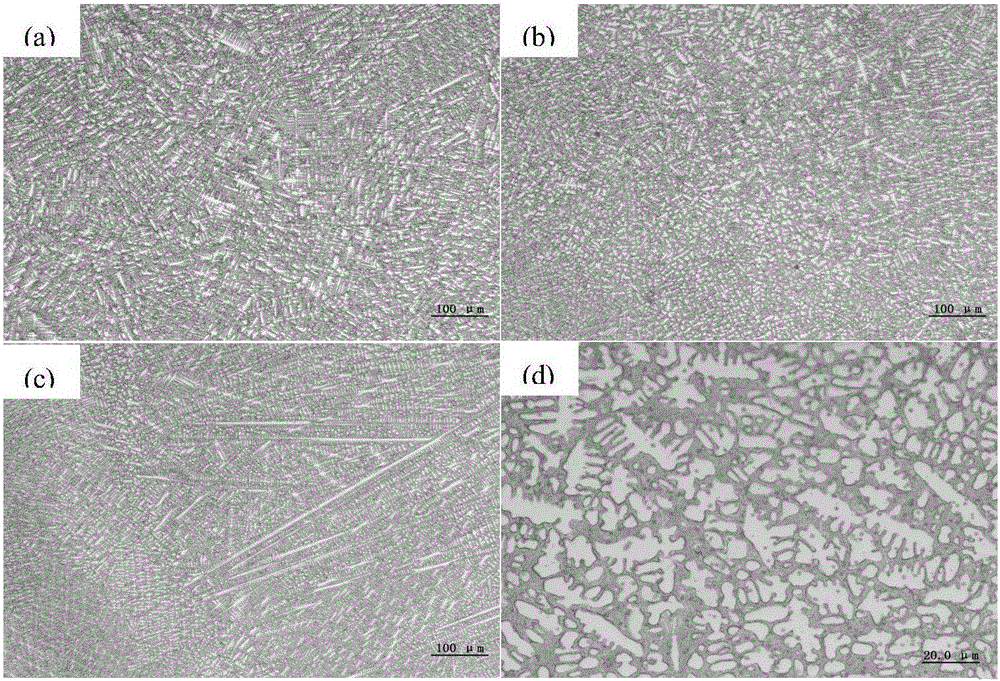

Image

Examples

Embodiment 1

[0049] A bio-bone composite material consisting of CoCrMo alloy powder, CeO 2 Alloy powder and ZrO 2 Alloy powder composite; wherein, by mass percentage, CoCrMo alloy powder: CeO 2 Alloy powder: ZrO 2 Alloy powder = 98:1:1, see Table 1; CoCrMo powder particle size range 100-200 mesh, CeO 2 Powder particle size range 0.5 ~ 1μm, ZrO 2 The powder particle size ranges from 30 to 80nm, and the three powders are spherical in shape; medical CoCrMo alloy powder is used, and the chemical composition is as follows: w (Cr) = 26%, w (Mo) = 6%, w (W) =5%, w(Si)=1%, w(Fe)=1%, w(C)=0.04%, and the balance is Co.

[0050] Table 1 Composition (wt.%) of bio-bone composite material

[0051]

[0052] The preparation method of biological bone composite material of the present invention is specifically as follows:

[0053] Step 1, mixing of composite powder:

[0054] (1) Mix 2.5g of cetyltrimethylammonium bromide with ethylene glycol solution and place in a 500mL beaker, mechanically stir ...

Embodiment 2

[0085] A bio-bone composite material consisting of CoCrMo alloy powder, CeO 2 Alloy powder and ZrO 2 Alloy powder composite; wherein, by mass percentage, CoCrMo alloy powder: CeO 2 Alloy powder: ZrO 2 Alloy powder = 97:1:2, see Table 1; CoCrMo powder particle size range 100-200 mesh, CeO 2 Powder particle size range 0.5 ~ 1μm, ZrO 2 The powder particle size ranges from 30 to 80nm, and the three powders are spherical in shape; medical CoCrMo alloy powder is used, and the chemical composition is as follows: w (Cr) = 25%, w (Mo) = 5%, w (W) =4%, w(Si)=0.5%, w(Fe)=0.8%, w(C)=0.02%, and the balance is Co.

[0086] The preparation method of biological bone composite material of the present invention is specifically as follows:

[0087] Step 1, mixing of composite powder:

[0088] (1) After mixing 2.5g of cetyltrimethylammonium bromide and ethylene glycol solution, place it in a 500mL beaker, stir mechanically at a speed of 300 rpm, and stir for 20min to form a mixed solution; ...

Embodiment 3

[0098] A bio-bone composite material consisting of CoCrMo alloy powder, CeO 2 Alloy powder and ZrO 2 Alloy powder composite; wherein, by mass percentage, CoCrMo alloy powder: CeO 2 Alloy powder: ZrO 2 Alloy powder = 96:1:3, see Table 1; CoCrMo powder particle size range 100-200 mesh, CeO 2 Powder particle size range 0.5 ~ 1μm, ZrO 2 The powder particle size ranges from 30 to 80nm, and the three powders are spherical in shape; medical CoCrMo alloy powder is used, and the chemical composition is as follows: w (Cr) = 27%, w (Mo) = 7%, w (W) =6%, w(Si)=1.2%, w(Fe)=1.2%, w(C)=0.05%, and the balance is Co.

[0099] The preparation method of biological bone composite material of the present invention is specifically as follows:

[0100] Step 1, mixing of composite powder:

[0101] (1) After mixing 5g of cetyltrimethylammonium bromide and ethylene glycol solution, place it in a 500mL beaker, stir it mechanically at a speed of 500 rpm, and stir for 15min to form a mixed solution;...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com