A kind of nitride fluorescent powder and preparation method thereof

A nitride phosphor, aluminum nitride technology, applied in chemical instruments and methods, luminescent materials, etc., can solve the problems of high cost of phosphor, poor chemical stability, chip damage, etc., to improve luminescence performance, chemical performance stability, The effect of high luminous efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0039] According to a second aspect of the present invention, a method for preparing a nitride phosphor is provided, comprising the following steps:

[0040] 1) According to chemical formula M p Q q N 3 The stoichiometric ratio of xR takes by weighing the nitride or oxide of M, the nitride or oxide of Q, the oxide of R, wherein: M is at least one in B, Al, Ga, Y, La; Q is At least one of Si, Ge, Ti, Sn; R is at least one of Eu, Ce, Li, Na, K; 0.8≤p≤1.5; 0.9≤q≤1.2; 0.001≤x≤0.2; Flux, the weighed raw materials are poured into the jet mill for jet milling to obtain the mixture M p Q q N 3 :xR;

[0041] 2) Press chemical formula A under protective atmosphere 1-x m p Q q N 3 : The stoichiometric ratio of xR Continue to weigh the mixture M p Qq N 3 : Nitride of xR and A, A is at least one of Be, Mg, Ca, Sr, Ba; add 0.001 to 0.03% by weight of silicon powder to prepare a mixture, and place the mixture in a vacuum ball milling tank, Add ball milling beads and mill evenly;...

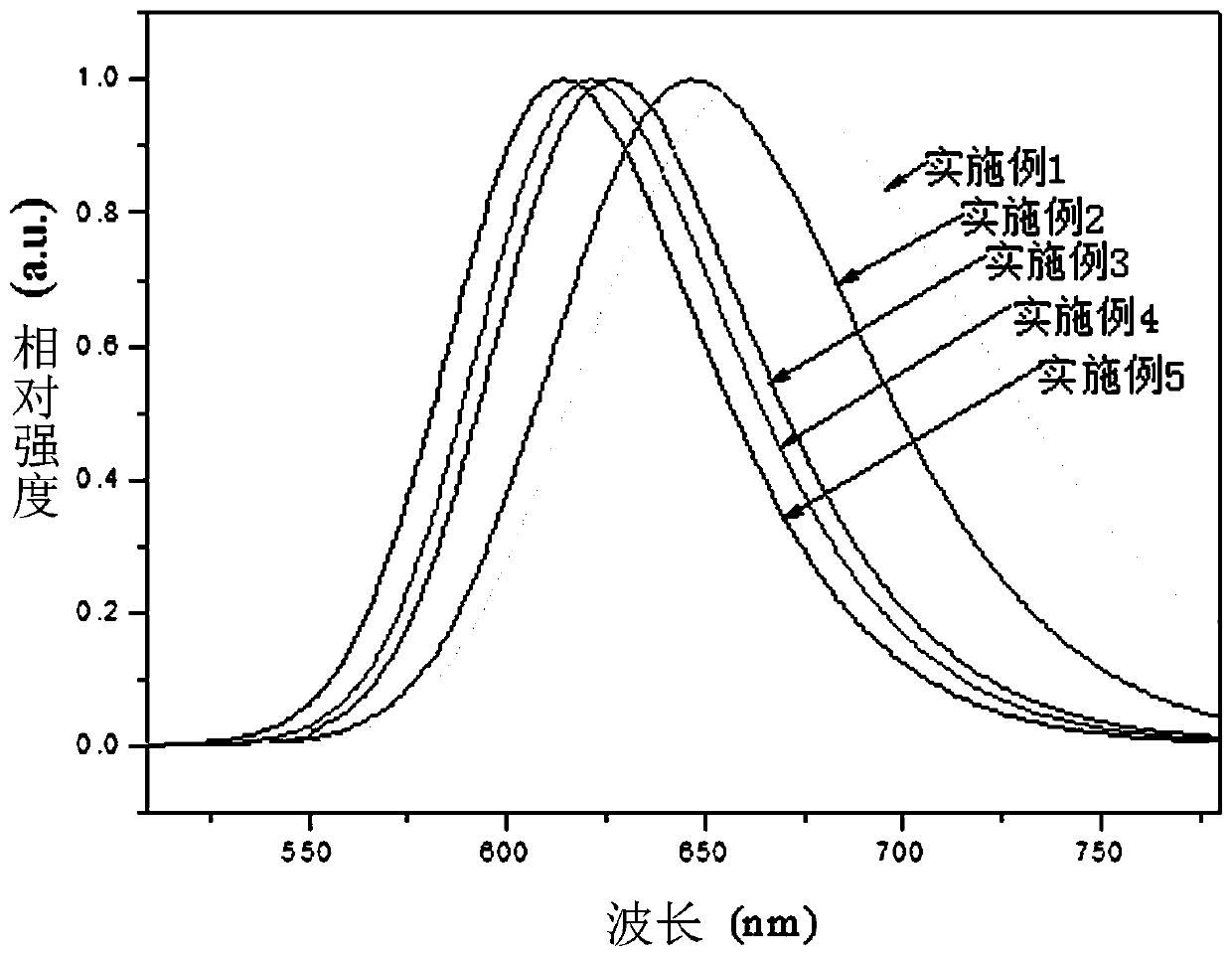

Embodiment 1

[0047] Example 1 Mg 0.005 Sr 0.090 Ca 0.865 AlSiN 3 :0.040Eu

[0048] 1) According to the chemical formula AlSiN 3 : The stoichiometric ratio of 0.040Eu weighs 4098.8g aluminum nitride, 4676.1g α-silicon nitride, 703.9g europium oxide, adds 148.3g strontium fluoride and 148.3g calcium fluoride as flux, and pours the weighed raw materials into The jet mill was used for jet milling, the air flow rate of the jet mill was 0.8 MPa, and the mixture A1 was obtained after jet milling for 5 hours.

[0049] 2) Under the protective atmosphere of high-purity nitrogen in a vacuum glove box, weigh 0.168g of magnesium nitride, 8.726g of strontium nitride, 42.745g of calcium nitride, and 0.298g of silicon powder, and place them in a vacuum ball milling tank with 97.754g of mixture A1. 149 g of zirconia beads were added, the rotation speed was 300 rpm, and the mixture B1 was obtained after ball milling for 4 hours.

[0050] 3) Put the mixture B1 under a nitrogen protective atmosphere, ap...

Embodiment 2

[0053] Example 2 Sr 0.255 Ca 0.700 al 0.992 Ga 0.008 SiN 3 :0.045Eu

[0054] 1) According to the chemical formula AlSiN 3 : The stoichiometric ratio of 0.045Eu takes by weighing 4066.0g aluminum nitride, 75.0g gallium oxide, 4676.1g α-silicon nitride, 791.8g europium oxide, adds 157.2g strontium fluoride and 157.2g calcium fluoride as flux, will weigh The raw materials taken were poured into a jet mill for jet milling, the air flow rate of the jet milling was 1 MPa, and the mixture A2 was obtained after jet milling for 6 hours.

[0055] 2) Under the protective atmosphere of high-purity nitrogen in a vacuum glove box, weigh 24.724g of strontium nitride, 34.591g of calcium nitride, and 0.477g of silicon powder, and place them in a vacuum ball mill jar with 99.233g of mixture A2, and add 159g of zirconia beads, The rotational speed was 200 rpm, and after ball milling for 3 hours, mixture B2 was obtained.

[0056] 3) Put the mixture B2 under a nitrogen protective atmosphere...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com