Compound functional black coloring agent and preparation method thereof

A technology of compound function and dyeing agent, applied in the direction of dyeing physical treatment, chemical instruments and methods, dyeing organic silicon compound treatment, etc. , The effect of simple operation process and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

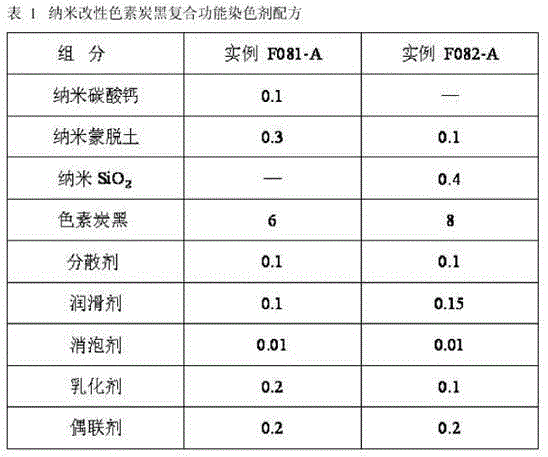

Embodiment 1

[0022] A composite functional black dyeing agent of model F081-A was prepared. It is prepared from the following raw materials in parts by weight: 0.1 part of nano-calcium carbonate, 0.3 part of nano-montmorillonite, 6 parts of pigment carbon black, 0.1 part of dispersant, 0.1 part of lubricant, 0.01 part of defoamer, and 0.2 part of emulsifier part, 0.2 part of coupling agent.

[0023] The preparation method of the composite function black dyeing agent of model F081-A, carry out as follows:

[0024] Step 1: Pre-dispersion

[0025] Put nano-calcium carbonate and nano-montmorillonite in a high-speed mixer; add dispersant, lubricant, and stir at high speed for 1-3 minutes; then add coupling agent and continue stirring for 1-2 minutes; then add pigment carbon black , and continue stirring for 5-8 minutes, keeping the temperature at 25°C~45°C.

[0026] Step 2: Ball Mill Dispersion or Ultrasonic Dispersion

[0027] Put the material obtained in step 1 into a ball mill or ultraso...

Embodiment 2

[0031] A composite functional black dyeing agent of model F082-A was prepared. It is prepared from the following raw materials in parts by weight: 0.1 part of nano-montmorillonite, 0.4 part of nano-silica, 8 parts of pigment carbon black, 0.1 part of dispersant, 0.15 part of lubricant, 0.01 part of defoamer, emulsifier 0.1 part, 0.2 part of coupling agent.

[0032] The preparation method of the composite function black dyeing agent of model F082-A, carry out as follows:

[0033] Step 1: Pre-dispersion

[0034] Put nano-montmorillonite and nano-silica in a high-speed mixer; add dispersant, lubricant, and stir at high speed for 1-3 minutes; then add coupling agent and continue stirring for 1-2 minutes; then add pigment carbon black, continue to stir for 5-8 minutes, and keep the temperature at 25°C~45°C.

[0035] Step 2: Ball Mill Dispersion or Ultrasonic Dispersion

[0036] Put the material obtained in step 1 into a ball mill or ultrasonic dispersion equipment for further d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com