Method for separating acetonitrile-methanol-benzene ternary azeotrope through three-tower pressure-swing distillation

A benzene ternary azeotrope and pressure swing rectification technology, which is used in distillation purification/separation, chemical instruments and methods, preparation of organic compounds, etc., can solve problems such as increasing workload, ensure product quality, and reduce equipment. The effect of improving investment costs and economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

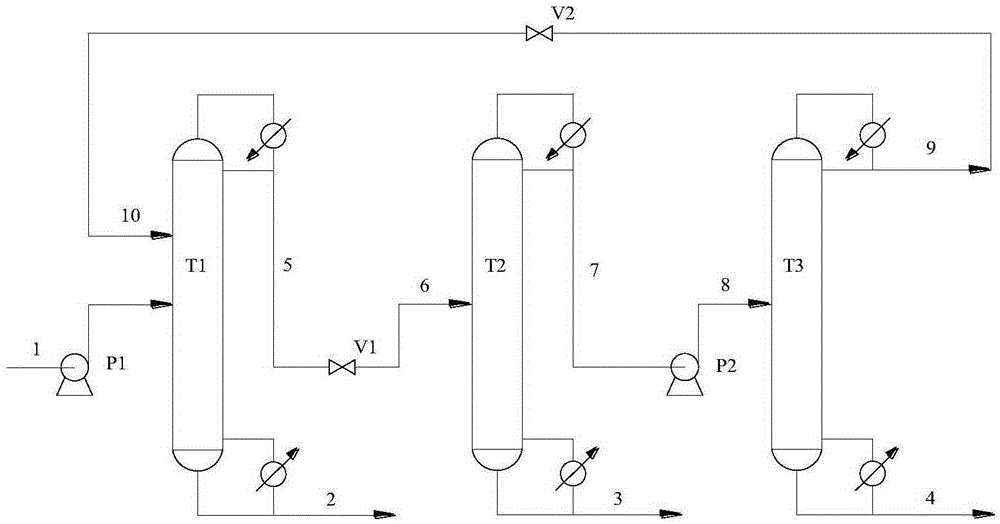

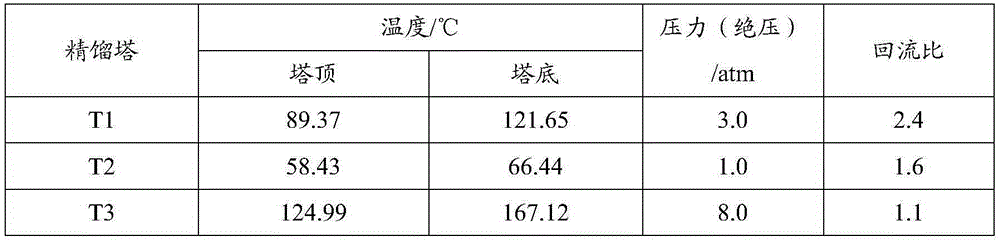

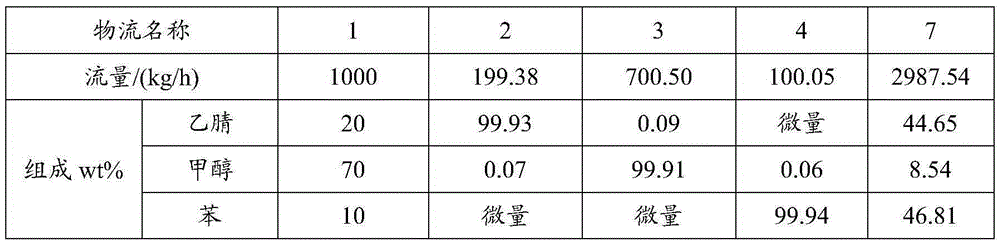

Embodiment 1

[0030] Feed flow rate 1000kg / h, temperature 25°C, pressure 3atm, mass composition: acetonitrile 20%, methanol 70%, benzene 10%. The effective theoretical plate number of the acetonitrile column is 55, the raw material liquid is introduced from the 27th plate, the circulating feed position is the 28th plate, the operating pressure is 3atm, the reflux ratio is 2.4, and the column diameter is about 1000mm; the effective theoretical plate of the methanol column The number is 50, and the production liquid at the top of the acetonitrile tower is introduced from the 12th plate, the operating pressure is 1atm, the reflux ratio is 1.6, and the tower diameter is about 900mm; The outlet liquid is introduced by the 11th plate, the operating pressure is 8atm, the reflux ratio is 1.1, and the tower diameter is about 750mm.

[0031] See Table 1 for process operating parameters, and Table 2 for feed and product logistics. It can be seen from the data in the table that after treatment, the re...

Embodiment 2

[0037] Feed flow rate 1200kg / h, temperature 25°C, pressure 3atm, mass composition: acetonitrile 20%, methanol 70%, benzene 10%. The effective theoretical plate number of the acetonitrile column is 54, the raw material liquid is introduced from the 36th plate, the circulating feed position is the 36th plate, the operating pressure is 3atm, the reflux ratio is 2.3, and the tower diameter is about 1000mm; the effective theoretical plate of the methanol tower The number is 47. The production liquid at the top of the acetonitrile tower is introduced from the 12th plate. The operating pressure is 1atm, the reflux ratio is 2.0, and the tower diameter is about 1000mm; The outlet liquid is introduced by the 13th plate, the operating pressure is 8atm, the reflux ratio is 1.0, and the tower diameter is about 750mm.

[0038] See Table 3 for process parameters and Table 4 for feed and product logistics. It can be seen from the data in the table that after treatment, the recovery rate of a...

Embodiment 3

[0044] Feed flow rate 800kg / h, temperature 25°C, pressure 3atm, mass composition: 20% acetonitrile, 70% methanol, 10% benzene. The effective theoretical plate number of the acetonitrile column is 42, the raw material liquid is introduced from the 30th plate, the circulating feeding position is the 29th plate, the operating pressure is 3atm, the reflux ratio is 1.3, and the column diameter is about 850mm; the effective theoretical plate of the methanol column The number is 44, the production liquid at the top of the acetonitrile tower is introduced from the 13th plate, the operating pressure is 1atm, the reflux ratio is 1.5, and the tower diameter is about 900mm; The outlet liquid is introduced from the eighth plate, the operating pressure is 8atm, the reflux ratio is 0.8, and the tower diameter is about 700mm.

[0045] See Table 5 for process operating parameters, and Table 6 for feed and product logistics. It can be seen from the data in the table that after treatment, the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com