Inclined feed cutting machine

A cutting machine and knife-feeding technology, applied to stone processing tools, working accessories, manufacturing tools, etc., can solve the problems of unsteady rotation, unsettled rotation, slow processing speed, etc., and achieve smooth cutting surface without steps and convenient Positioning and locking, good rotation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

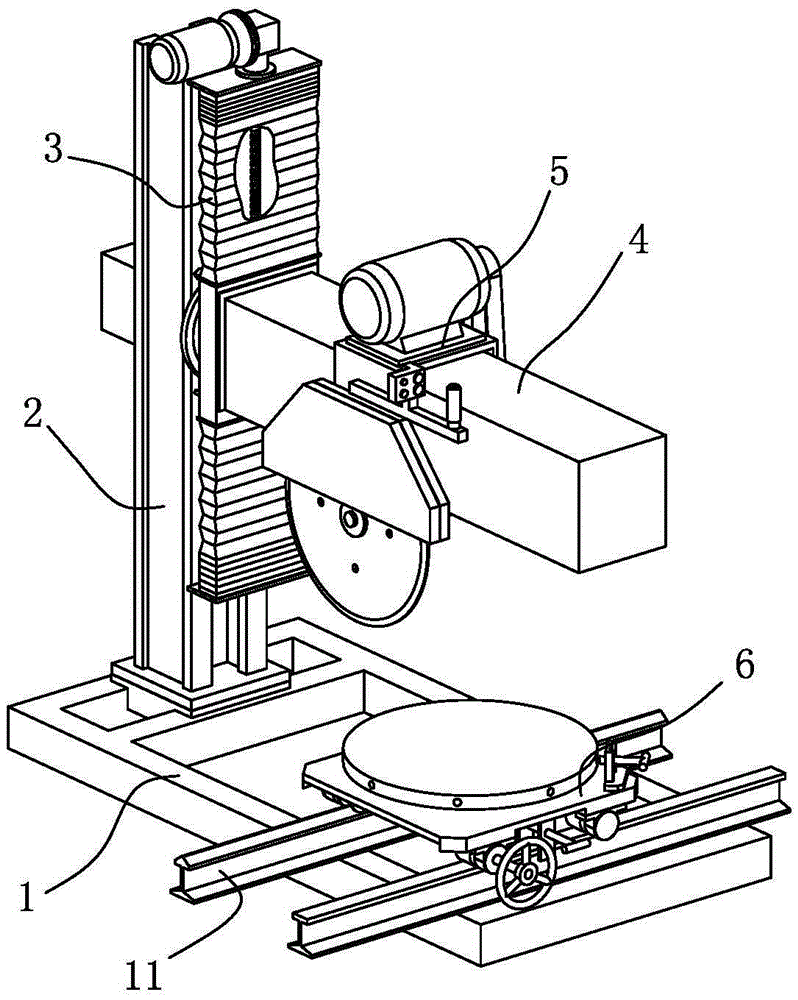

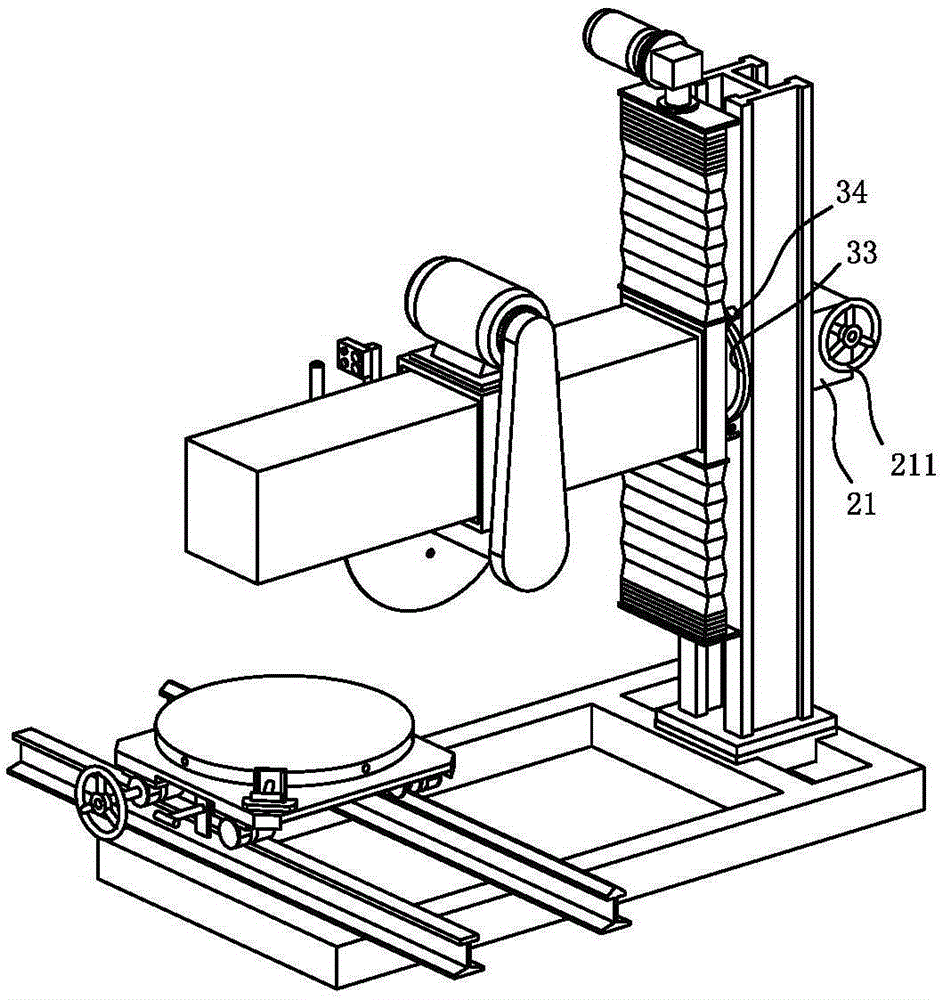

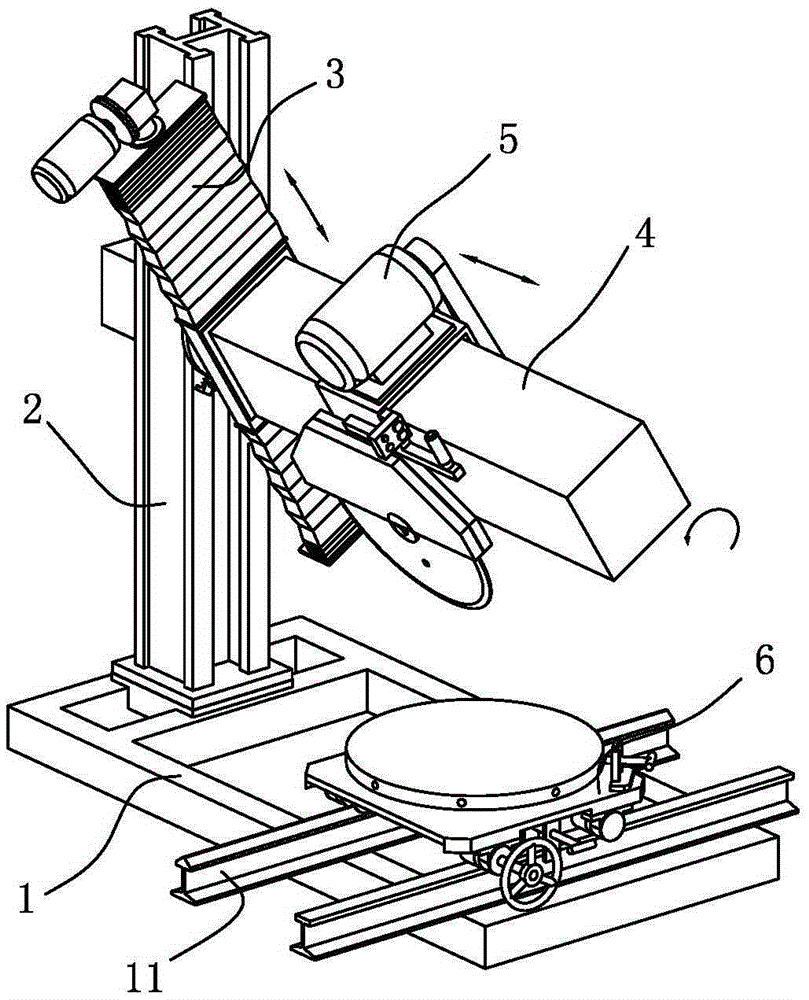

[0028] Such as Figure 1-Figure 2 As shown, a kind of oblique knife cutting machine of the present invention comprises base 1, and described base 1 is provided with column 2, and described column 2 is provided with the lifting guide rail 3 that can rotate around the horizontal axis, and described lifting guide rail 3 There is a horizontal guide rail 4 that can move up and down, and a cutting device 5 that can move left and right is provided on the horizontal guide rail 4; a material table guide rail 11 is provided on the base 1, and a material table guide rail 11 that can move forward and backward is provided. Platform 6, said material platform 6 is provided with a turntable 7;

[0029] The column 1 is provided with a rotating device that drives the lifting guide rail 3 to rotate, and the lifting guide rail 3 is provided with a lifting device ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com