Automatic feeding mechanism of CNC high-speed machining center

A processing center and automatic feeding technology, which is applied in the direction of metal processing machinery parts, metal processing, metal processing equipment, etc., can solve the problems of not being able to drill on multiple sides, low drilling efficiency, inaccurate positioning, etc., and achieve good fixing effect , Easy to process drilling, fast feeding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

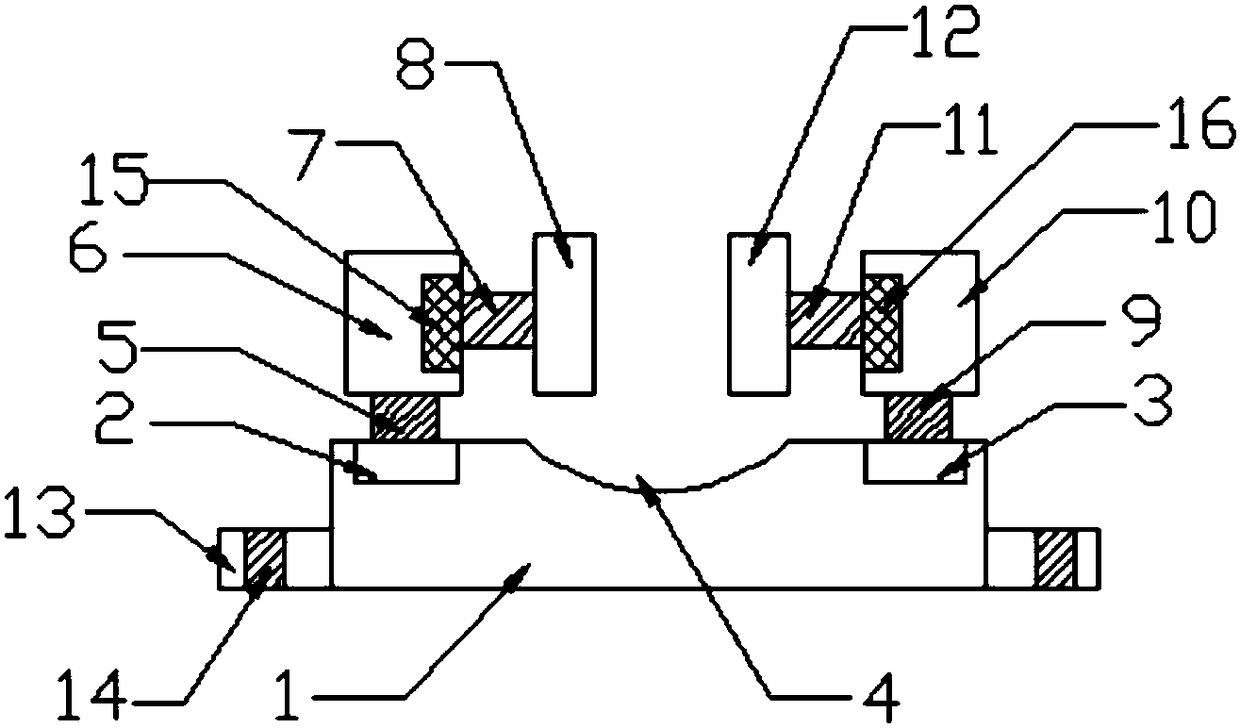

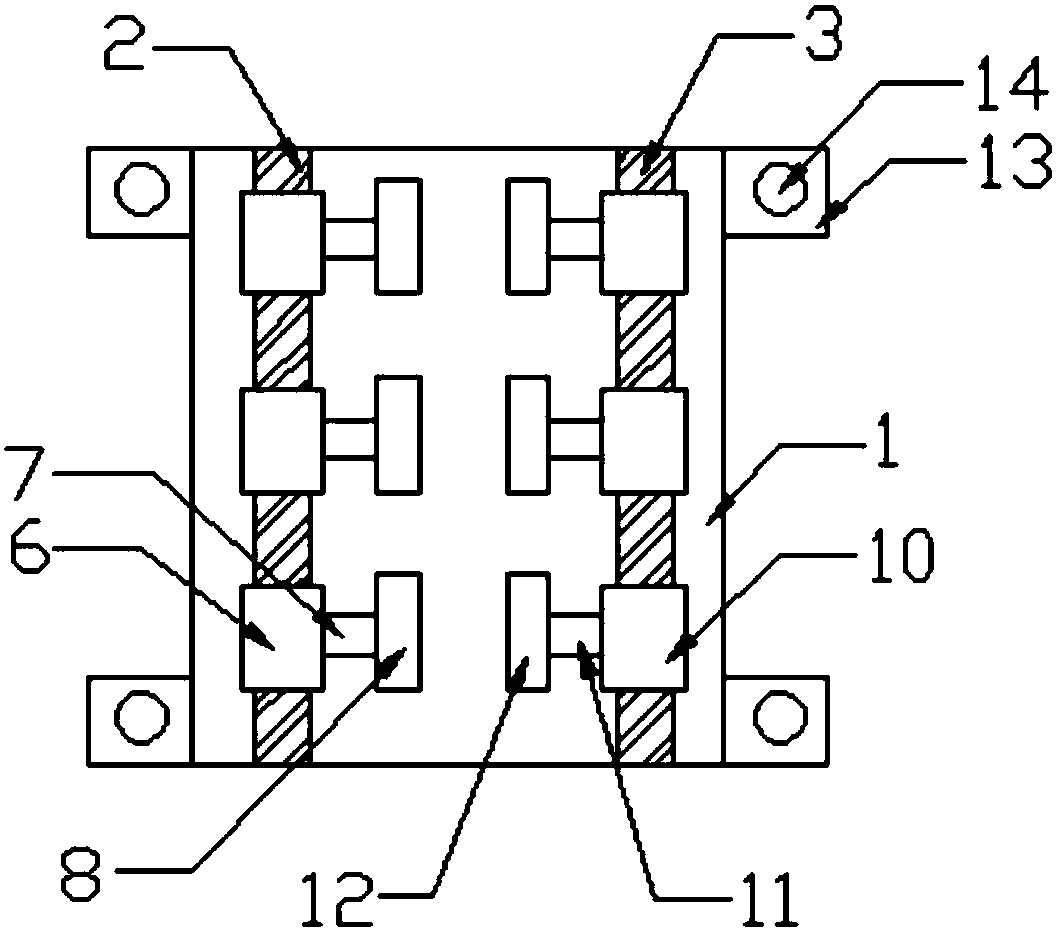

[0017] Example: such as Figure 1-2 As shown, a CNC high-speed machining center automatic feeding mechanism of the present invention includes a base 1, the top of the base 1 is provided with a first chute 2, a second chute 3, and a groove 4, and the groove 4 is arranged on the first chute Between the groove 2 and the second chute 3, the first chute 2 is provided with a first electric slider 5, the top of the first electric slider 5 is provided with a first fixed block 6, and one end of the first fixed block 6 is provided with There is a first electric rotary table 15, one side of the first electric rotary table 15 is provided with a first electric telescopic rod 7, one side of the first electric telescopic rod 7 is provided with a first splint 8, and the second chute 3 is provided with There is a second electric slider 9, the top of the second electric slider 9 is provided with a second fixed block 10, one end of the second fixed block 10 is provided with a second electric rot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com