Press moulding machine for manufacturing and packaging wood shaping plates

A technology for packaging and compression molding machines, which is applied in the field of compression molding machines, can solve the problems of physical and chemical parameters that are difficult to achieve in packaging construction, and achieve the effects of simple structure, high production efficiency, and rapid discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

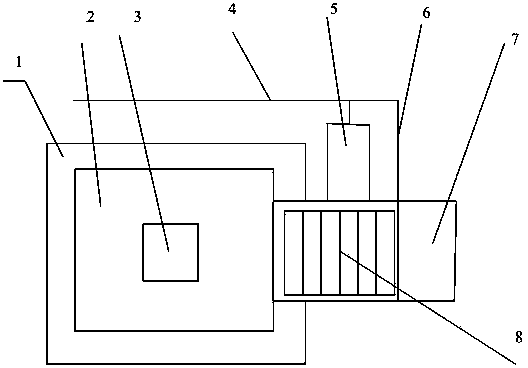

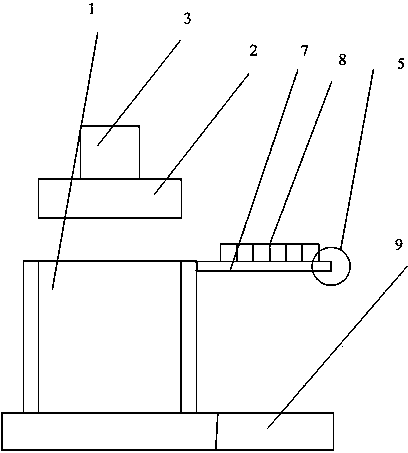

[0017] see figure 1 : The molding machine for producing the wood template for packaging mainly consists of a base mold 1 and a down-pressing top mold 2 arranged on the top of the base mold 1. drive unit 3.

[0018] A transfer platform 7 is connected to the side wall of the base mold 1 .

[0019] The side wall of the transmission platform 7 is provided with a stepping drive motor 5, the output shaft of the stepping drive motor 5 is connected with a guide rail 4, and the guide rail 4 is connected with a transmission baffle plate 6, and the transmission baffle plate 6 is in stepping mode. Driven by the drive motor 5, it moves on the guide rail 4, and its moving direction is that the transfer platform 7 moves towards the direction directly above the base mold 1.

[0020] The bottom of the base mold 1 is provided with a heating device.

[0021] The heating device includes a heat conductor and a temperature control box 9 connected to the heat conductor, and the heat conductor is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com