Machining method for titanium alloy thin-walled part

A processing method and technology for thin-walled parts, applied in metal processing equipment, metal processing machinery parts, manufacturing tools, etc., can solve problems such as poor processing economic performance, low processing efficiency, and cumbersome procedures, so as to improve processing performance and improve processing efficiency. Efficiency, high speed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described in detail below in conjunction with specific embodiments, which are explanations of the present invention rather than limitations.

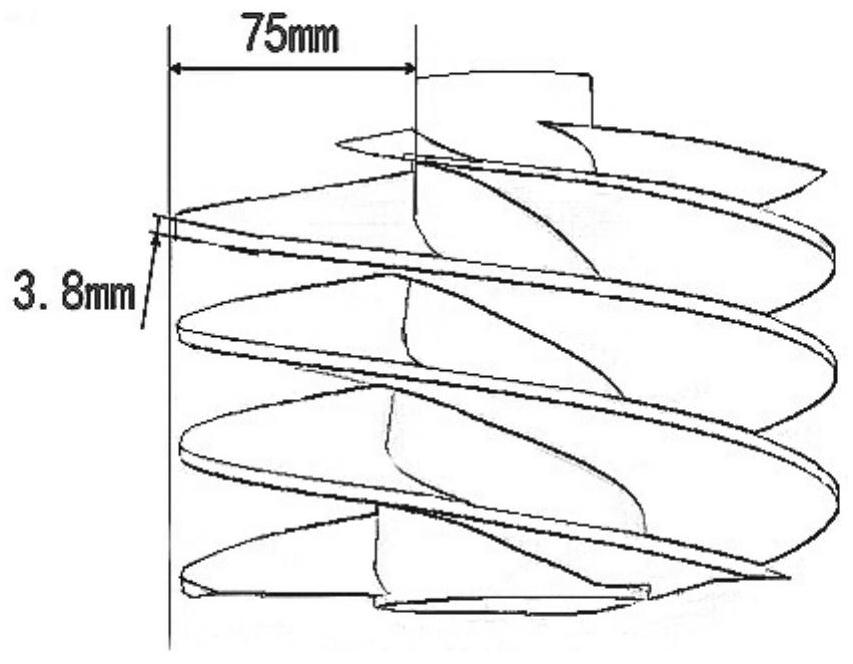

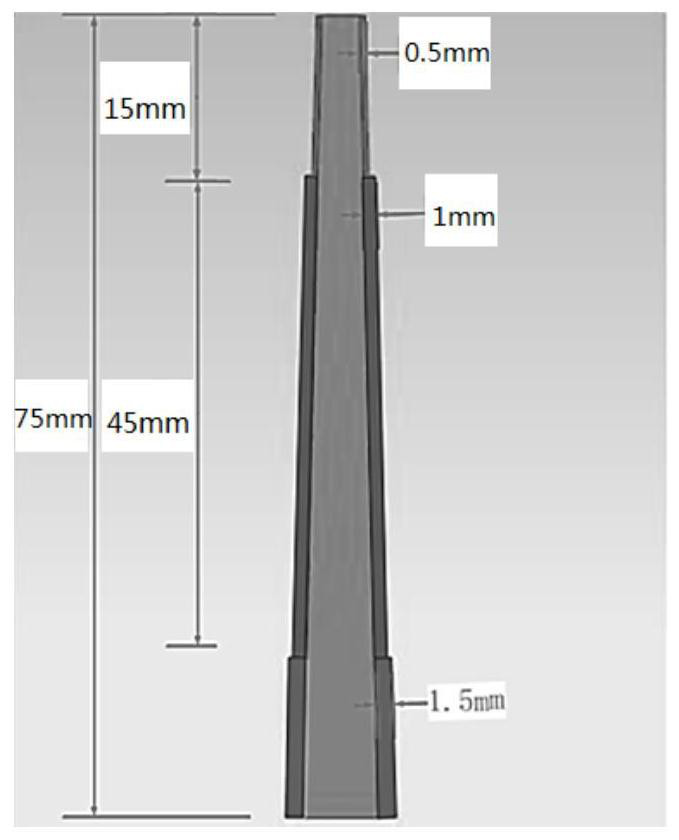

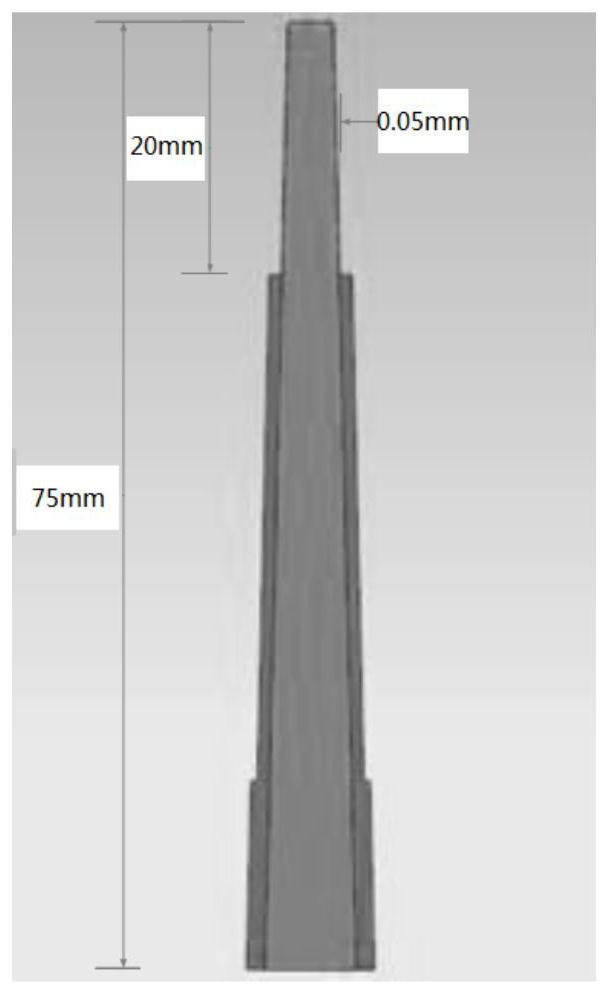

[0034] The invention provides a processing method of titanium alloy thin-walled parts, according to figure 1 The model diagram of the thin-walled part is shown. The overhanging depth and wall-thickness ratio of the thin-walled part exceeds 19, which is a typical thin-walled part. The amount of metal removed during processing is high, and there are problems such as deformation of the thin-walled part, which requires special processing technology. processing.

[0035] A processing method for a titanium alloy thin-walled part, comprising:

[0036] S1 clamping, fixing the workpiece on the processing tooling, and reserving the cutting path of the tool;

[0037] S2 Rough machining, layered milling along the upper end to the lower end of the workpiece to remove the blank amount, forming a stepped ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com