Automatic tapping machine power head capable of fast feed and fast return

A technology of automatic tapping machine and power head, which is applied in the direction of thread cutting machine, metal processing machinery parts, feeding device, etc. It can solve the problems of unsatisfactory processing and limit the tapping efficiency of tapping machine, and achieve the effect of improving tapping efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

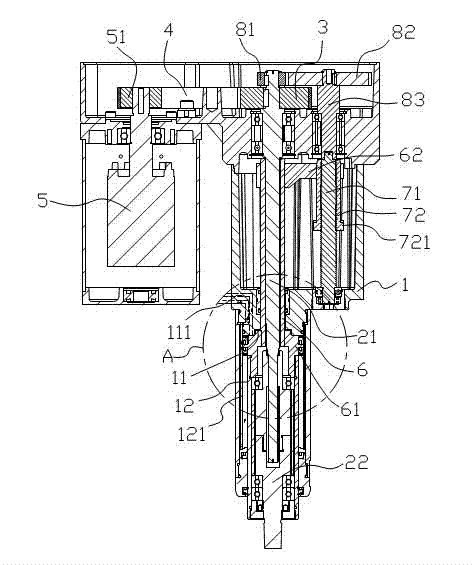

[0016] Such as figure 1 and 2 As shown, a fast-forward and fast-reverse automatic tapping machine power head includes a headstock 1 and a main shaft arranged in the headstock, and the main shaft includes an outer spline shaft 21 and an inner spline shaft 22 .

[0017] Wherein the head of the outer spline shaft 21 goes deep into the tail of the inner spline shaft 22 and is connected by the inner and outer splines between the two. The tail of the external spline shaft 21 is provided with a driven wheel 3, and the driven wheel 3 is connected to the driving wheel 51 of the power motor 5 through a synchronous belt 4.

[0018] Described outer spline shaft 21 outer cover is provided with a guide shaft 6, and the inner spline shaft 22 is connected by bearing in the head of guide shaft 6, and a piston 61 is installed in the middle part of the outer side of guide shaft 6, and described piston 61 is arranged on the headstock 1. An axially sealed chamber is completely separated into an ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com