Spot welding method of galvanized steel sheets

A galvanized steel sheet and spot welding technology, applied in welding equipment, resistance welding equipment, manufacturing tools, etc., can solve problems such as poor welding, and achieve the effect of solving poor welding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

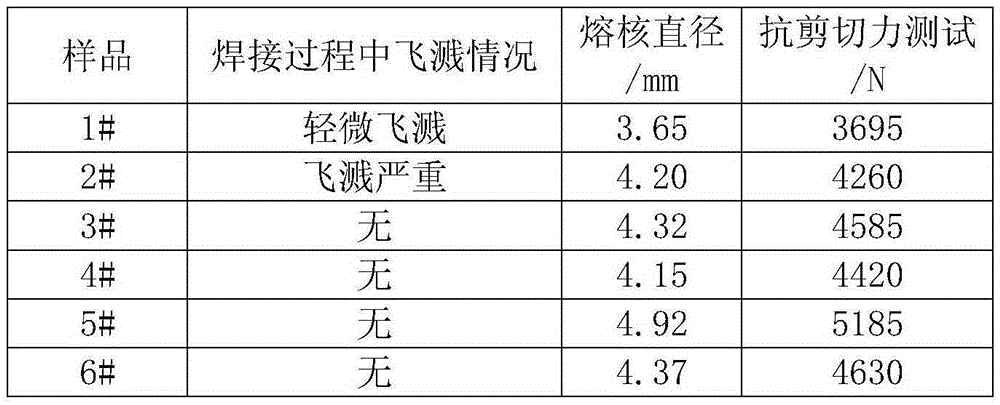

[0015] Below in conjunction with embodiment the present invention is further described:

[0016] A method of spot welding galvanized steel sheets, comprising the following steps in sequence:

[0017] A. The two electrodes of the spot welding machine respectively press the two galvanized steel sheets to be welded;

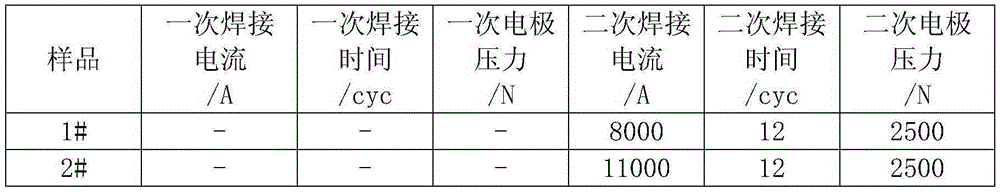

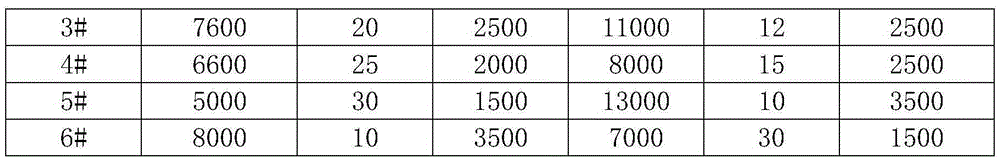

[0018] B. Perform the first welding current output: the welding current is set to 5000-8000 amps, the discharge duration is 10-30 cycles, and the electrode pressure value is 1500-3500 N;

[0019] C. Carry out the second welding current output: the welding current is set to 7000-13000 amps, the discharge duration is 10-30 cycles, and the electrode pressure value is 1500-3500 N;

[0020] D. The two electrodes are separated from the two galvanized steel sheets, and the spot welding is completed.

[0021] In the spot welding method of the present invention, after the two electrodes of the spot welding machine are respectively pressed against two galvanized steel sheet...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com