Metal base plate used for welding power module

A metal substrate and power module technology, applied in electrical components, electrical solid devices, circuits, etc., can solve the problems of power module life reduction, temperature rise, poor welding, etc., to improve service life and reliability, and uniform temperature distribution , The effect of saving manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

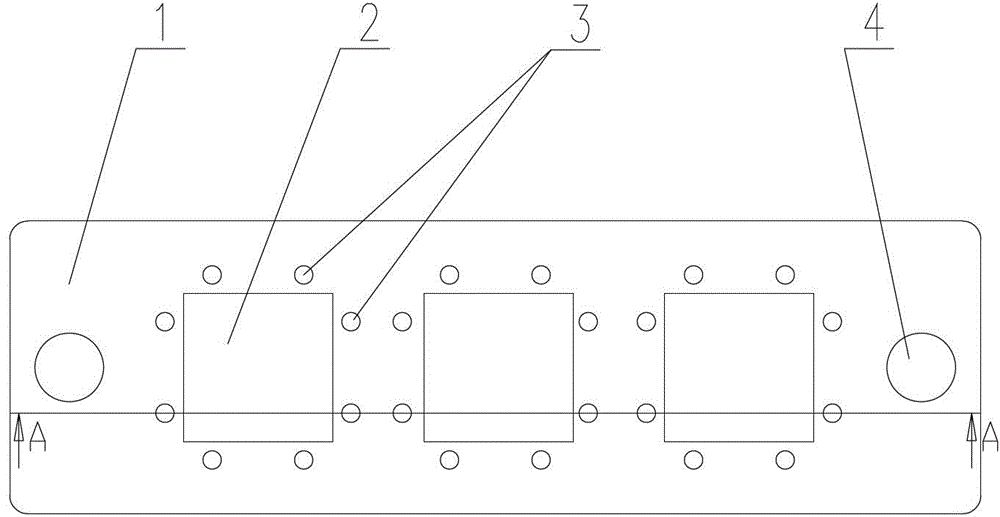

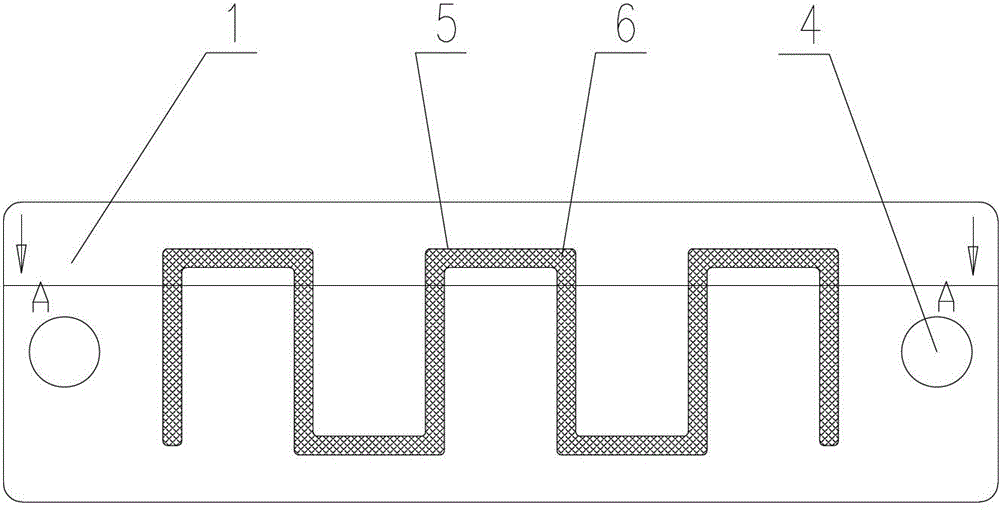

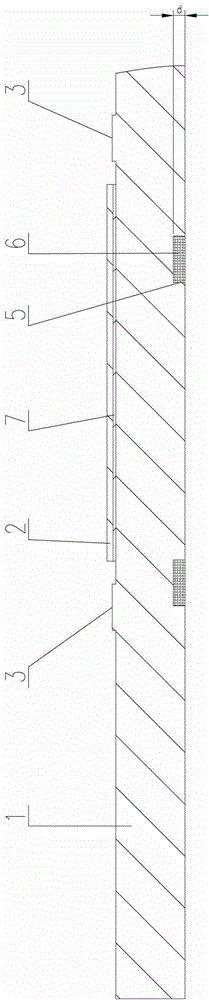

[0019] See Figure 1~3 As shown, the metal substrate used for welding power modules of the present invention includes a board body 1, and the board body 1 is provided with mounting holes 4, and the metal substrate is conveniently connected to the shell through fasteners, and the metal substrate is connected to the heat sink. , the heat is forced out through the radiator.

[0020] figure 1 , 2 , 4, the front of the plate body 1 of the metal substrate of the present invention is at least provided with four or more position-limiting protrusions 3 that limit the outer periphery of the solder layer 7, and the height of the position-limiting protrusions 3 on the plate body 1 is greater than that of the solder The height of the layer 7 not only facilitates the placement of the solder sheet, but also limits the solder before and after melting through the limiting protrusion 3 to ensure that the soldering position of the chip 2 remains unchanged. See figure 1 As shown, the limiting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com