Novel antibacterial polyester peach skin imitation fabric

A technology of imitating peach skin velvet and fabrics, which is applied in the fields of biochemical fiber processing, textile and papermaking, fiber processing, etc., can solve the problems of insufficient antibacterial properties and high price of fabrics, and achieve good antibacterial properties, improved softness, and soft gloss. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

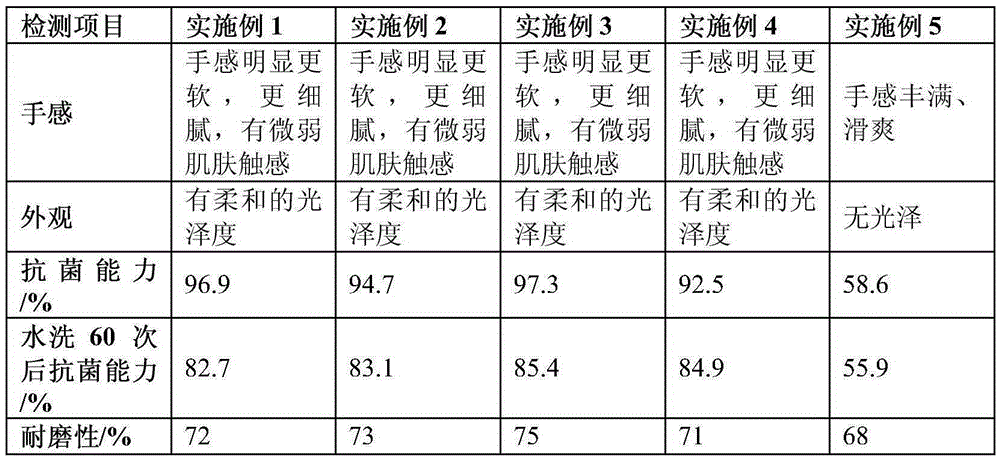

Examples

Embodiment 1

[0021] A preparation method of a novel antibacterial imitation jeanette fabric, the steps are as follows:

[0022] (1) The blending ratio of soybean fiber and cotton fiber is 3:7 for blending according to the weight percentage; conventional singeing, whitening and drying are carried out to the blended fabric;

[0023] Wherein the concentration of the caustic soda that adopts during singeing is 90g / L,

[0024] (2) Grinding: use metal abrasive grains for dry grinding;

[0025] (3) Microbial modification treatment:

[0026] Bacillus licheniformis, Sphingomonas, Lactococcus lactis, and Bifidobacterium are formulated into a composite bacterial agent according to the quantitative ratio of 1:0.2:1.5:0.2;

[0027] The brushed fabric is evenly sprayed with bacteria agent, and fermented at 38°C for 52 hours;

[0028] After fermentation, wash with warm water and dry;

[0029] (5) Polishing treatment: polishing the modified fabric;

[0030] (6) Dyeing according to conventional method...

Embodiment 2

[0032] A preparation method of a novel antibacterial imitation jeanette fabric, the steps are as follows:

[0033] (1) The blending ratio of soybean fiber and cotton fiber is 3:7 for blending according to the weight percentage; conventional singeing, whitening and drying are carried out to the blended fabric;

[0034] Wherein the concentration of the caustic soda that adopts during singeing is 105g / L,

[0035] (2) Grinding: use metal abrasive grains for dry grinding;

[0036] (3) Microbial modification treatment:

[0037] Bacillus licheniformis, Sphingomonas, Lactococcus lactis, and Bifidobacterium are formulated into a composite bacterial agent according to the quantitative ratio of 1:0.2:1.5:0.1;

[0038] The brushed fabric is evenly sprayed with bacteria agent and fermented at 38°C for 65 hours;

[0039] After fermentation, wash with warm water and dry;

[0040] (5) Polishing treatment: polishing the modified fabric;

[0041] (6) Dyeing according to conventional method...

Embodiment 3

[0043] A preparation method of a novel antibacterial imitation jeanette fabric, the steps are as follows:

[0044] (1) The blending ratio of soybean fiber and cotton fiber is 3:7 for blending according to the weight percentage; conventional singeing, whitening and drying are carried out to the blended fabric;

[0045] Wherein the concentration of the caustic soda that adopts during singeing is 100g / L,

[0046] (2) Grinding: use metal abrasive grains for dry grinding;

[0047] (3) Microbial modification treatment:

[0048] Bacillus licheniformis, Sphingomonas, Lactococcus lactis, and Bifidobacterium are formulated into a composite bacterial agent according to the quantitative ratio of 1:0.2:1.5:0.2;

[0049] The brushed fabric is evenly sprayed with bacteria agent and fermented at 38°C for 60 hours;

[0050] After fermentation, wash with warm water and dry;

[0051] (5) Polishing treatment: polishing the modified fabric;

[0052] (6) Dyeing according to conventional method...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com