High-stability salt-containing clothes washing effervescent tablet and preparation method thereof

An effervescent tablet, high stability technology, applied in chemical instruments and methods, detergent materials, detergent compounding agents, etc., can solve problems such as poor solubility, achieve good foaming effect, easy storage and use, cost low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] (1) Take by weighing 15g sodium dodecylbenzenesulfonate, 10g alkyl glucoside, 30g zeolite, 6.5g oxalic acid, 10g sodium chloride, 1.5g gum arabic, 0.1g edetate tetrasodium salt, and well mixed;

[0031] (2) The particles are passed through a 20-mesh sieve, and granulated;

[0032] (3) 20g of sodium carbonate and 1g of talcum powder are added to the granules of step (2), mixed evenly, and compressed into tablets;

[0033] (4) Dissolve 3g of cellulose acetate phthalate in 97mL of acetone to make a 3% solution

[0034] (5) Spray the tablet prepared in step (3) on the tablet through step (4), and after the solvent volatilizes, a relatively hard coating film is formed to obtain a laundry effervescent tablet;

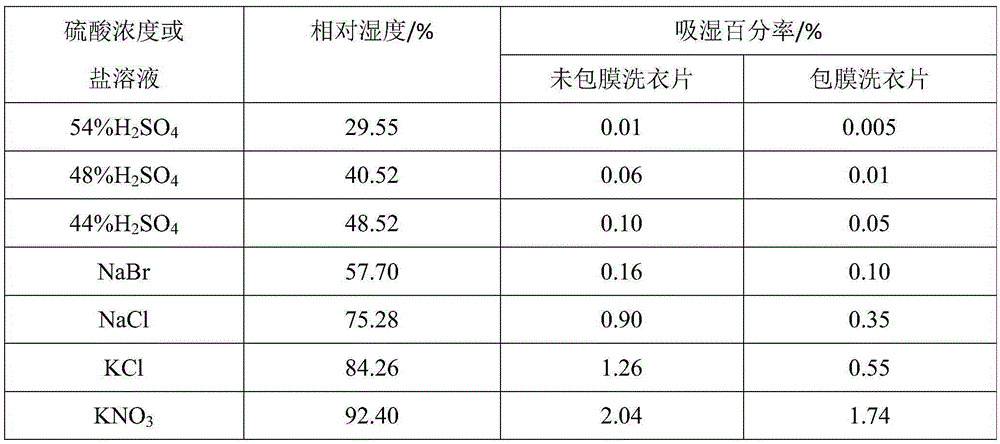

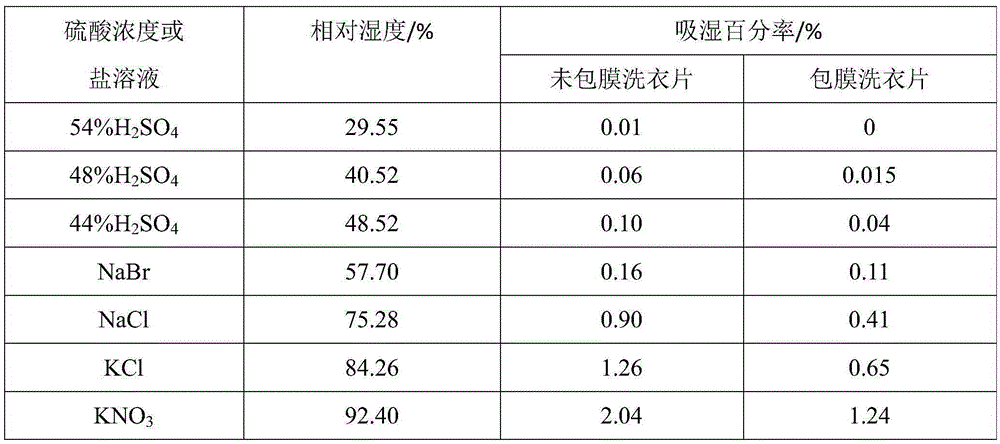

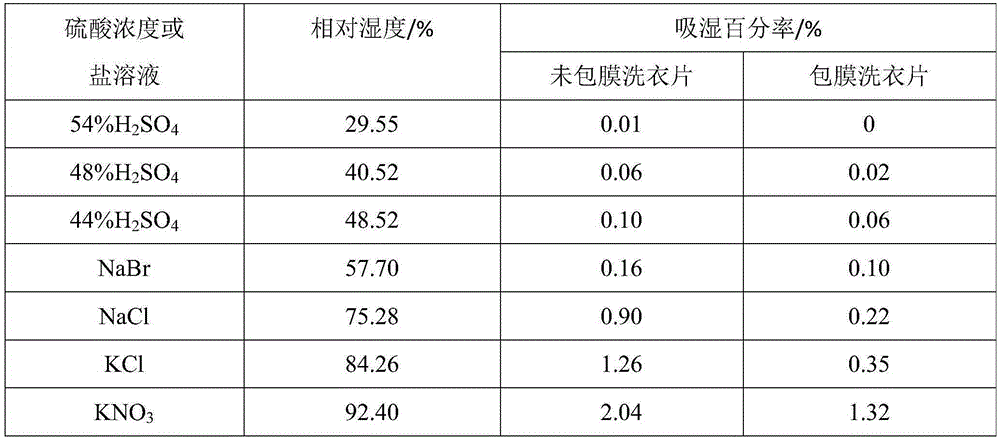

[0035] (6) Carry out the decontamination performance test according to the decontamination test method in the national standard GB / T13174-2008 according to the laundry detergent. The constant temperature in the constant temperature incubator was kept constant for 24...

Embodiment 2

[0042] (1) Weigh 20g ammonium lauryl sulfate, 7g cocoic acid monoethanolamide, 25g layered sodium silicate, 7.5g citric acid, 15g sodium chloride, 3g polyvinylpyrrolidone, 0.5g ethylenediaminetetraacetic acid Tetrasodium salt, mix well;

[0043] (2) The particles are passed through a 20-mesh sieve, and granulated;

[0044] (3) 22.5g of sodium carbonate and 1g of magnesium stearate are added to the granules of step (2), mixed evenly, and compressed into tablets;

[0045] (4) 1.5g of hydroxypropyl methylcellulose and 1.0g of cellulose acetate phthalate were dissolved in 98.5mL of acetone to make a 3% solution;

[0046] (5) Spray the tablet prepared in step (3) on the tablet through step (4), and after the solvent volatilizes, a relatively hard coating film is formed to obtain a laundry effervescent tablet;

[0047] (6) Carry out the decontamination performance test according to the decontamination test method in the national standard GB / T13174-2008 according to the laundry det...

Embodiment 3

[0053] (1) Weigh 15g sodium dodecylbenzene sulfonate and 10g α-olefin sulfonate, 5g alkyl glycoside, 35g sodium sulfate, 8g tartaric acid, 5g sodium chloride, 5g guar gum, 0.2g ethylenediaminetetra Tetrasodium acetate, mix well;

[0054] (2) The particles are passed through a 20-mesh sieve, and granulated;

[0055] (3) 22.5g sodium carbonate and 2g magnesium stearate are added to the granules of step (2), mixed evenly, and compressed;

[0056] (4) 1.5g hydroxypropyl methylcellulose and 1.0g polyacrylic acid resin were dissolved in 98.5mL acetone to make a 3% solution;

[0057](5) Spray the tablet prepared in step (3) on the tablet through step (4), and after the solvent volatilizes, a relatively hard coating film is formed to obtain a laundry effervescent tablet;

[0058] (6) Carry out the decontamination performance test according to the decontamination test method in the national standard GB / T13174-2008 according to the laundry detergent, and perform the hygroscopic perfor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com