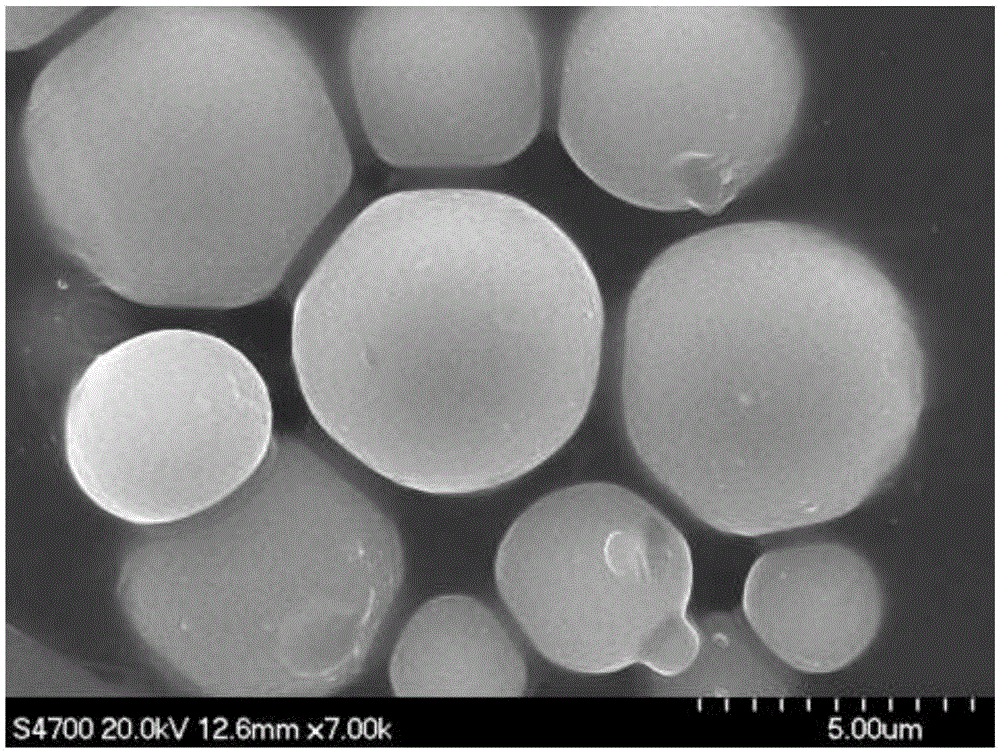

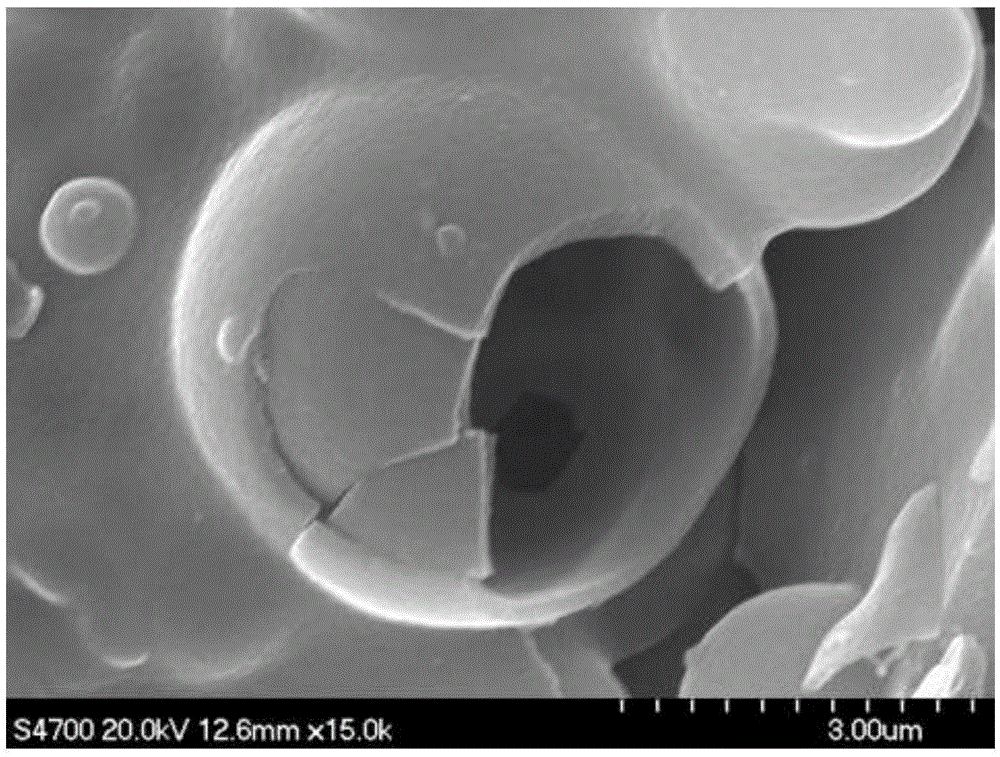

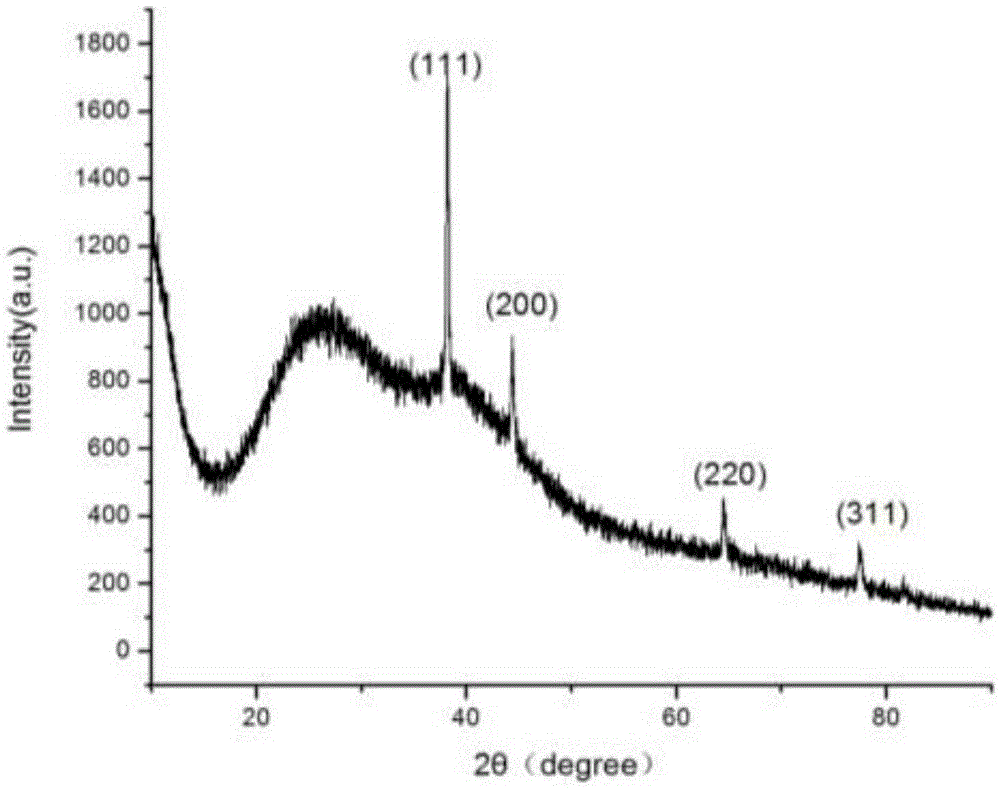

Silver/silicon dioxide double layer wall material-based multifunctional microcapsule phase-change material, and preparation method thereof

A technology of silica and phase change materials, applied in the direction of microcapsule preparation, microsphere preparation, heat exchange materials, etc., can solve the problems of supercooling, single function, poor thermal conductivity, etc. Broadening, strengthening and densifying effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034](1) Preparation of core material emulsion:

[0035] In a water bath at a temperature of 80°C, mix 2.5g of n-eicosane, 0.6g of cetyltrimethylammonium bromide, 3.5g of tetraethylorthosilicate, 1g of γ-mercaptopropyltrimethoxysilane, and 50ml of formaldehyde Amides were mixed evenly, and stirred at 300r / min for 1h to obtain a uniform and stable emulsion.

[0036] (2) Preparation of mercapto-containing silica inner wall:

[0037] Keep the temperature constant, add 25ml of 40wt.% hydrochloric acid aqueous solution dropwise to the emulsion formed in step 1, stir for 4h at a speed of 350r / min, turn off the stirring, and mature for 24h; take out the product, filter it, and rinse it several times with ultrapure water , to a pH value of 7, and dried at 50°C.

[0038] (3) Preparation of nano-silver outer layer wall material:

[0039] Raise the temperature to 80°C, under a nitrogen atmosphere, take 0.2g of microcapsules from step (2), mix with 95ml N,N-dimethylformamide, 4g polyv...

Embodiment 2

[0042] (1) Preparation of core material emulsion:

[0043] In a water bath at a temperature of 40°C, mix 2g of n-octadecane, 1g of sodium dodecylsulfonate, 3g of tetraethyl orthosilicate, 1g of γ-mercaptopropyltrimethoxysilane, and 45ml of formamide. Stirring for 1 h at a rotating speed of 1 / min to obtain a uniform and stable emulsion.

[0044] (2) Preparation of mercapto-containing silica inner wall:

[0045] Keep the temperature constant, add 40ml of 30wt.% hydrochloric acid aqueous solution dropwise to the emulsion formed in step 1, stir at 500r / min for 4h, turn off the stirring, and mature for 24h; take out the product, filter it, and rinse it several times with ultrapure water , to a pH value of 7, and dried at 50°C.

[0046] (3) Preparation of nano-silver outer layer wall material:

[0047] Raise the temperature to 90°C, under a nitrogen atmosphere, take 0.2g of microcapsules from step (2), mix with 95ml N,N-dimethylformamide, 4g polyvinylpyrrolidone, stir for 0.5h to...

Embodiment 3

[0050] (1) Preparation of core material emulsion:

[0051] In a water bath at a temperature of 40°C, mix 6g of n-nonadecane, 2g of cetyltrimethylammonium bromide, 6g of methyltrimethoxysilane, 0.3g of Span80, 0.4g of Tween, and 60ml of formamide. Stirring for 1.5 h at a speed of min, a uniform and stable emulsion was obtained.

[0052] (2) Preparation of mercapto-containing silica inner wall:

[0053] Keep the temperature constant, add 45ml of 35wt.% hydrochloric acid aqueous solution dropwise to the emulsion formed in step 1, stir at 350r / min for 5h, turn off the stirring, and mature for 24h; take out the product, filter it, and rinse it several times with ultrapure water , to a pH value of 7, and dried at 50°C.

[0054] (3) Preparation of nano-silver outer layer wall material:

[0055] Raise the temperature to 50°C, under nitrogen atmosphere, take 0.3g of microcapsules from step (2), mix with 94ml N,N-dimethylformamide, 5g polyvinylpyrrolidone, stir for 0.5h to exclude ox...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com