Cracking resistance modified polyethylene material and preparation method therefor

A polyethylene and anti-cracking technology, which is applied in the field of anti-cracking modified polyethylene materials and their preparation, can solve problems such as cracking of the outer layer of polyethylene, and achieve the effects of prolonging the service life, improving the range of adapting to temperature changes, and having advanced formulations.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

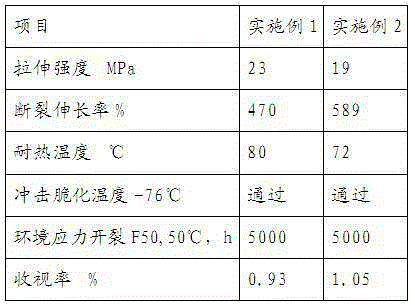

Examples

Embodiment 1

[0030] (1) Linear low-density polyethylene particles (Qilu Petrochemical 7042), 4 packs of 100kg, filled into a plastic mill for grinding, grinding process parameters: grinding disc temperature ≤ 65 ° C, grinding disc rotation speed 2500-3200rpm;

[0031] (2) Take antioxidant 1010 (BASF AG), 2kg; antioxidant 168 (BASF AG), 2kg; peroxide (dicumyl peroxide DCP) 6kg, take the linearity obtained in step (1) 100kg of low-density polyethylene powder is filled into a high-speed mixer and mixed to prepare a composite powder. The mixing process parameters are: temperature 80-120°C, speed ≥ 800rpm, mixing time 3-10min;

[0032] (3) Melt and blend the composite powder obtained in step (2) with a twin-screw extruder, extrude and granulate to obtain a modified masterbatch, and the extrusion process parameters: the melt temperature is 110-210°C, and the screw speed is 100-800rpm; 25kg of modified masterbatch, bagged and set aside;

[0033] (4) Take 4 packages of high-density polyethylene, ...

Embodiment 2

[0036] (1) Linear low-density polyethylene particles (Qilu Petrochemical 7042), 4 packs of 100kg, filled into a plastic mill for grinding, grinding process parameters: grinding disc temperature ≤ 65 ° C, grinding disc rotation speed 2500-3200rpm;

[0037] (2) Take antioxidant 1010 (BASF AG), 1.5kg; antioxidant 168 (BASF AG), 1.5kg; peroxide (dicumyl peroxide DCP) 3kg, take step (1) to get 100kg of linear low-density polyethylene powder is filled into a high-speed mixer and mixed to prepare a composite powder. The mixing process parameters are: temperature 80-120°C, speed ≥ 800rpm, mixing time 3-10min;

[0038] (3) Melt and blend the composite powder obtained in step (2) with a twin-screw extruder, extrude and granulate to obtain a modified masterbatch, and the extrusion process parameters: the melt temperature is 110-210°C, and the screw speed is 100-800rpm; 25kg of modified masterbatch, bagged and set aside;

[0039] (4) Take 4 bags of high-density polyethylene, 100kg; 30kg ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com