Butyl alcohol and 2-ethyl hexanol production equipment industrial waste comprehensive utilization method

A technology for industrial waste and production equipment, applied in the petroleum industry, chemical instruments and methods, fuels, etc., can solve problems such as high energy consumption for cracking, poor economic benefits, complex composition, etc., to achieve economic benefits, solve environmental problems, and solve Effects of emissions problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

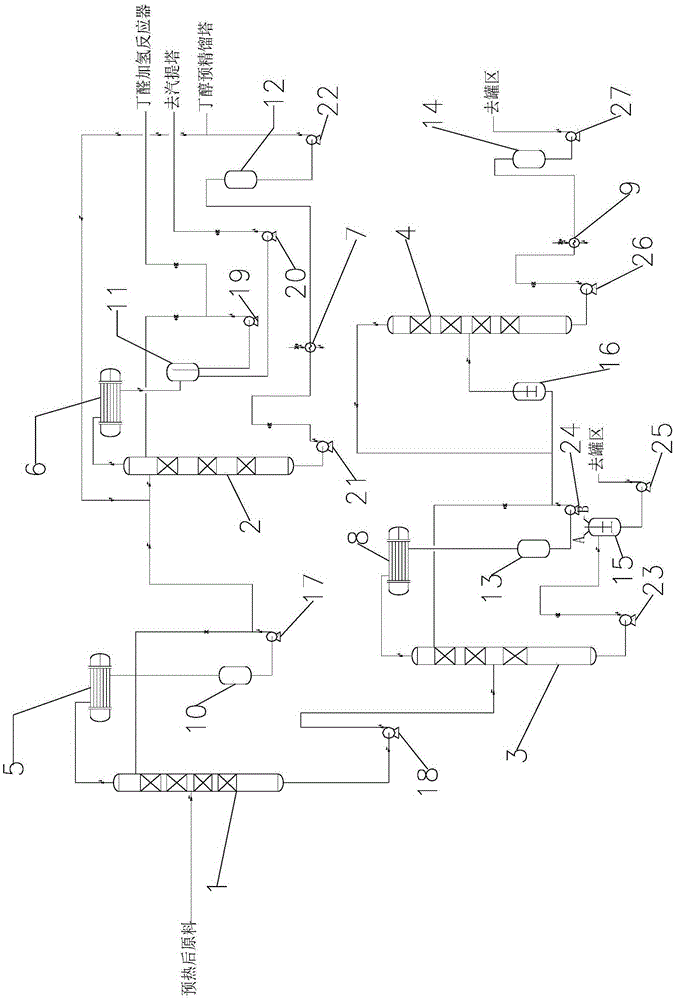

[0024](1) Firstly, the industrial waste of butanol and octanol is pumped into the first rectification tower 1, and the separation is carried out under the condition that the pressure and temperature at the top of the tower are 28KPa and 75.1°C respectively, and the industrial waste is divided into C4 with single molecule carbon number not greater than 4 Components and components greater than C4. Extract no more than C4 light components from the top of the tower, condense through the first condenser 5 and enter the first liquid receiving tank 10, and a part of the liquid pumped out from the first liquid receiving tank 10 is sent into the first rectifying tower as The reflux liquid and another part of the liquid are pumped into the second rectification column 2; the components larger than C4 are extracted from the bottom of the first rectification column 1 and enter the third rectification column 3.

[0025] (2) The light components entering the second rectification tower 2 are ...

Embodiment 2

[0030] (1) Firstly, the industrial waste of butanol and octanol is pumped into the first rectification tower 1, and the separation is carried out under the condition that the pressure and temperature at the top of the tower are respectively 30KPa and 75.1°C, and the industrial waste is divided into C4 having a single molecule carbon number not greater than 4 Components and components greater than C4. Extract no more than C4 light components from the top of the tower, condense through the first condenser 5 and enter the first liquid receiving tank 10, and a part of the liquid pumped out from the first liquid receiving tank 10 is sent into the first rectifying tower as The reflux liquid and another part of the liquid are pumped into the second rectification column 2; the components larger than C4 are extracted from the bottom of the first rectification column 1 and enter the third rectification column 3.

[0031] (2) The light components entering the second rectification tower 2...

Embodiment 3

[0036] (1) Firstly, the butanol industrial waste is pumped into the first rectification tower 1, and the separation is carried out under the conditions of the tower top pressure and temperature of 32KPa and 79.1°C respectively, and the industrial waste is divided into C4 with a single molecule carbon number not greater than 4 Components and components greater than C4. Extract no more than C4 light components from the top of the tower, condense through the first condenser 5 and enter the first liquid receiving tank 10, and a part of the liquid pumped out from the first liquid receiving tank 10 is sent into the first rectifying tower as The reflux liquid and another part of the liquid are pumped into the second rectification column 2; the components larger than C4 are extracted from the bottom of the first rectification column 1 and enter the third rectification column 3.

[0037] (2) The light components entering the second rectification tower 2 are separated under the conditio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com