Preparation method of vertically aligned hafnium disulfide nanosheets by chemical vapor deposition

A chemical vapor deposition and hafnium disulfide technology, which is applied in the field of chemical vapor deposition preparation of hafnium disulfide nanosheets, can solve the problems of no hafnium disulfide nanosheets, no hafnium disulfide materials, etc., and achieves good uniformity, The effect of high surface activity and large area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] (1) The silicon dioxide / silicon substrate was ultrasonically cleaned with deionized water, acetone, and ethanol for 2 minutes respectively, then rinsed with deionized water, and finally dried with nitrogen.

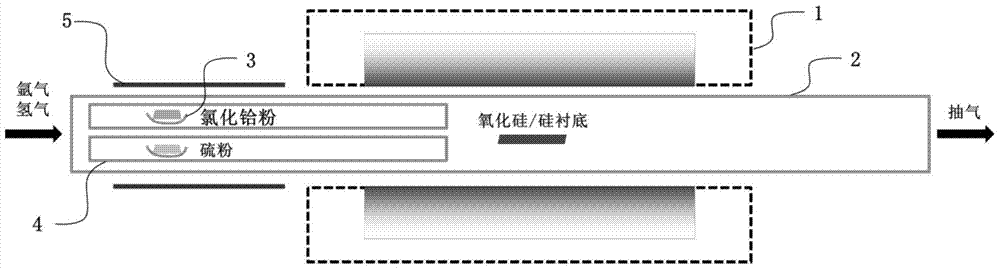

[0032] (2) Place the silicon dioxide / silicon substrate in the central temperature zone of the quartz tube 2 of the vacuum tube furnace 1 . Weigh 200mg of sulfur powder and 100mg of hafnium tetrachloride powder (purity not less than 99.9%) into the quartz boat 3, and then place them in two small quartz tubes 4 respectively, and the small quartz tubes 4 are placed in the tube furnace Outside the heating zone, external winding heating tape 5, such as figure 1 shown.

[0033] (3) Evacuate the vacuum tube furnace to a high vacuum with a molecular pump, so that the pressure in the tube furnace is reduced to 10 -3 Pa, argon gas and hydrogen gas are introduced at a rate of 10 sccm, and the pressure in the chamber is maintained at 18 Pa.

[0034] (4) Raise the central te...

Embodiment 2

[0039] (1) The sapphire substrate was ultrasonically cleaned with deionized water, acetone, and ethanol for 2 minutes respectively, then rinsed with deionized water, and finally dried with nitrogen.

[0040] (2) Place the sapphire substrate in the central temperature zone of the quartz tube 2 of the vacuum tube furnace 1 . Weigh 300mg of sulfur powder and 100mg of hafnium tetrachloride powder (purity not less than 99.9%) and put them into the quartz boat 3, then place them in two small quartz tubes 4 respectively, and place the small quartz tubes 4 in the tube furnace Outside the heating zone, external winding heating tape 5, such as figure 1 shown.

[0041] (3) Evacuate the vacuum tube furnace to a high vacuum with a molecular pump, so that the pressure in the tube furnace is reduced to 10 -3 Pa, argon gas and hydrogen gas are introduced at a rate of 10 sccm, and the pressure in the chamber is maintained at 18 Pa.

[0042] (4) Raise the central temperature zone of the tube...

Embodiment 3

[0047](1) The graphene substrate (graphene transferred to silicon oxide / silicon) was ultrasonically cleaned with deionized water, acetone, and ethanol for 2 minutes, then rinsed with deionized water, and finally dried with nitrogen.

[0048] (2) The graphene substrate is placed in the central temperature zone of the quartz tube 2 of the vacuum tube furnace 1 . Weigh 400mg of sulfur powder and 100mg of hafnium tetrachloride powder (purity not less than 99.9%) into the quartz boat 3, then place it in two small quartz tubes 4, and place the small quartz tubes 4 in a tube furnace for heating area outside, externally wound heating tape 5, such as figure 1 shown.

[0049] (3) Evacuate the vacuum tube furnace to a high vacuum with a molecular pump, so that the pressure in the tube furnace is reduced to 10 -3 Pa, argon gas and hydrogen gas are introduced at a rate of 10 sccm, and the pressure in the chamber is maintained at 18 Pa.

[0050] (4) Raise the central temperature zone of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com