Preparation method of submicron-scale barium titanate powder

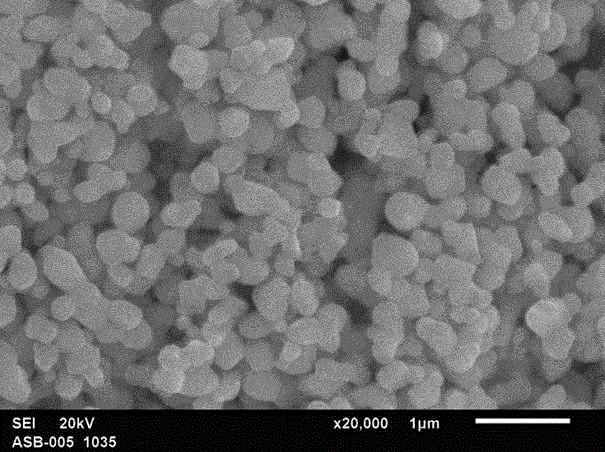

A barium titanate powder, submicron technology, applied in the field of material chemistry, can solve the problems of difficult to obtain a homogeneous mixture, difficult to obtain barium titanate powder, large barium titanate particles, etc., and achieve high uniformity , high crystallinity, the effect of expanding industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0015] Refer to Table 1-1, 1-2, 2-1, 2-2 and figure 1 , figure 2 The present invention is further described, a preparation method of submicron barium titanate powder, comprising the following steps:

[0016] (1) Metatitanic acid, the precursor of titanium oxide, is used as the titanium source, and it is mixed with barium carbonate by high-efficiency grinding and dispersion. Metatitanic acid and barium carbonate of different purity and particle size are mixed with barium carbonate according to a certain barium-titanium ratio, and high-efficiency grinding is used for uniform dispersion. The barium titanate powder was synthesized by phase method calcining, and the suitable metatitanic acid and barium carbonate were determined by comparative analysis of the particle size uniformity and crystallinity of the barium titanate powder;

[0017] (2) Using the combination of raw materials determined in the first step, the raw materials are mechanically mixed, and the barium titanate pow...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com