A tin dioxide nanorod with controllable aspect ratio and preparation method thereof

A tin dioxide and nanorod technology, applied in tin oxide and other directions, can solve the problems of poor nanorod dispersion, low nanorod yield, low tin source concentration, etc., and achieve high crystallinity, high product yield, and preparation technology. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

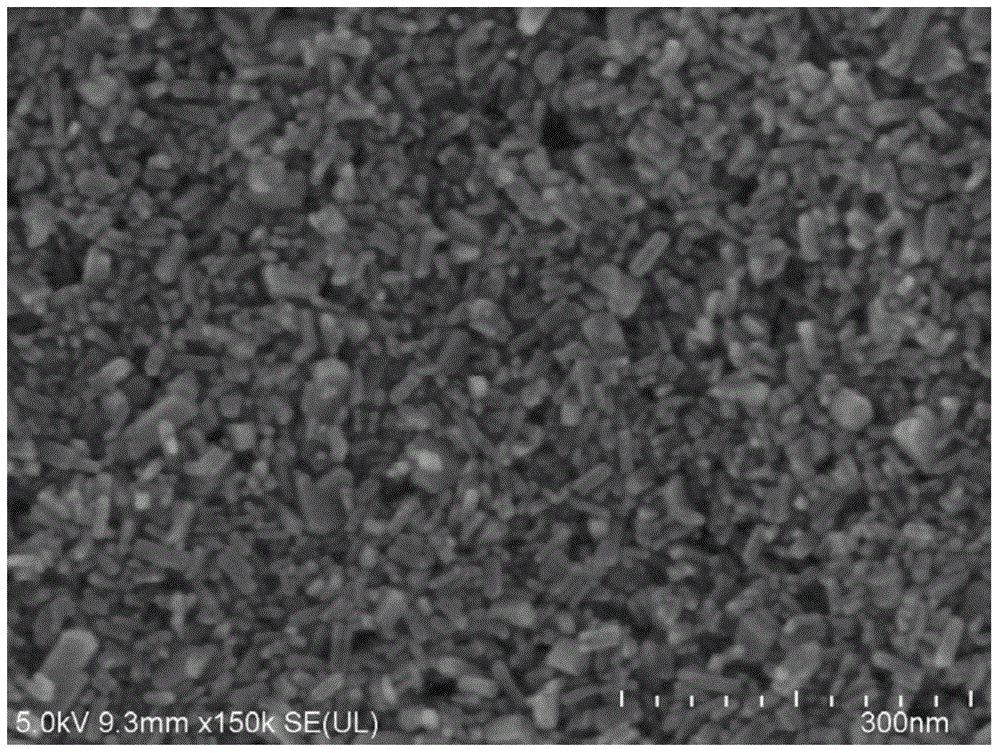

[0039] Take 20 milliliters of pure water and 30 milliliters of cyclohexane and mix, add 1 gram of sodium hydroxide and 3.51 grams of tin tetrachloride pentahydrate successively under the condition of magnetic stirring to form a layered mixed solution; transfer the above mixed solution to the reaction kettle The solvothermal reaction was carried out in the reactor, the filling rate of the reactor was 60%, the reaction temperature was controlled at 200°C, and the reaction time was 24 hours; after the reaction was completed, the precipitate was taken out, washed repeatedly with pure water, and centrifuged. 1.51 grams of tin dioxide nanorods with good crystallinity can be obtained in a single reaction, and the yield is higher than that reported in the usual literature. figure 1 The field emission scanning electron microscope image of the tin dioxide nanorods prepared in Example 1 shows that the tin dioxide nanorods have an average diameter of about 15 nanometers and a length of 20 ...

Embodiment 2

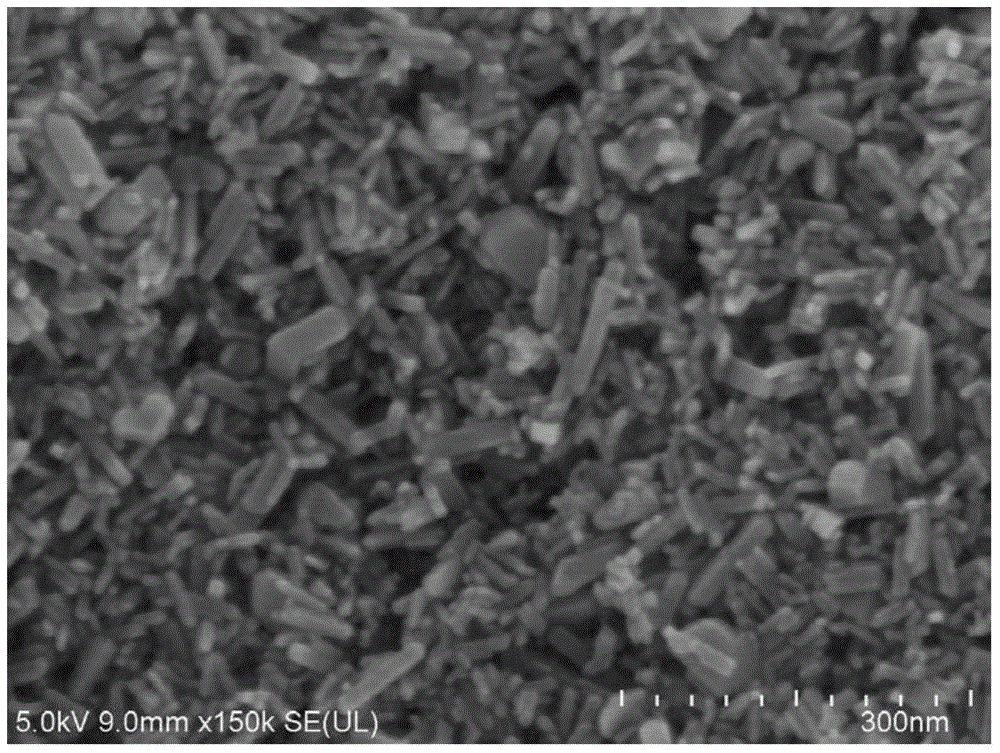

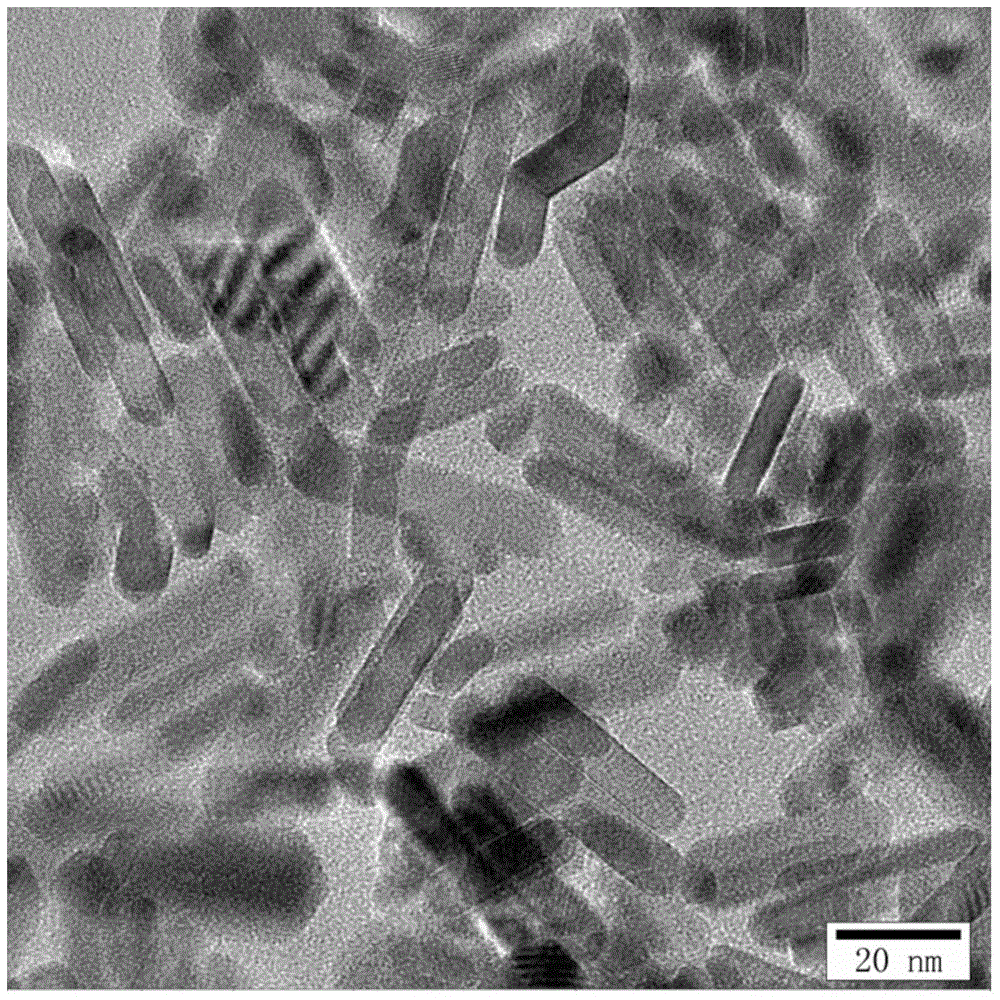

[0041] Take 10 milliliters of pure water and 40 milliliters of cyclohexane and mix them, add 1 gram of sodium hydroxide and 3.51 grams of tin tetrachloride pentahydrate successively under the condition of magnetic stirring to form a layered mixed solution; transfer the above mixed solution to the reaction kettle The solvothermal reaction was carried out in the reactor, the filling rate of the reactor was 60%, the reaction temperature was controlled at 200°C, and the reaction time was 24 hours; after the reaction was completed, the precipitate was taken out, washed repeatedly with pure water, and centrifuged. figure 2The field emission scanning electron microscope image of the tin dioxide nanorods prepared for Example 2 shows that the tin dioxide nanorods have an average diameter of about 15 nanometers and a length of 30 to 80 nanometers. image 3 The transmission electron microscope image of the tin dioxide nanorods prepared in Example 2, it can be seen from the figure that th...

Embodiment 3

[0043] Mix 5 milliliters of pure water and 45 milliliters of cyclohexane, add 1 gram of sodium hydroxide and 3.51 grams of tin tetrachloride pentahydrate successively under the condition of magnetic stirring to form a layered mixed solution; transfer the above mixed solution to the reaction kettle The solvothermal reaction was carried out in the reactor, the filling rate of the reactor was 60%, the reaction temperature was controlled at 200°C, and the reaction time was 24 hours; after the reaction was completed, the precipitate was taken out, washed repeatedly with pure water, and centrifuged. Figure 4 The field emission scanning electron microscope image of the tin dioxide nanorods prepared for Example 3 shows that the tin dioxide nanorods have an average diameter of about 15 nanometers and a length of 60-100 nanometers.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com