Petroleum coke based activated carbon for electrode material of supercapacitor, preparation method therefor and use thereof

A technology for activated carbon and petroleum coke, applied in the field of activated carbon preparation, can solve the problems of insufficient contact, large consumption of raw materials, and high production cost, and achieve the effects of suppressing gas swelling, prolonging cycle life, and enhancing the degree of contact.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

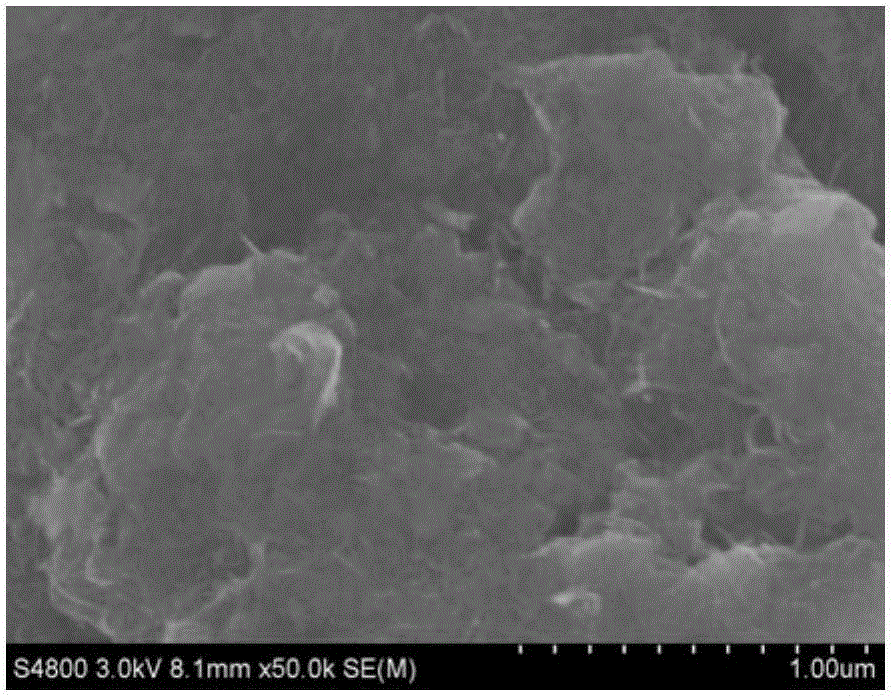

[0080] Put 50 g of carbonized petroleum coke powder that has been pulverized by airflow to a particle size distribution D50 of about 8 to 10 μm into a rotary oxidation furnace (Xianyang Languang Thermal Technology), and feed 200 L / h of compressed air for 30 to 60 minutes, and then at 20°C / min The heating rate is raised to 350 ° C, and after 1 hour of heat preservation, it is rapidly cooled to room temperature in an oxidizing atmosphere to obtain a pre-oxidized precursor; the petroleum coke pre-oxidized precursor is mixed according to the mass ratio of NaOH: pre-oxidized precursor = 3: 1 Put it evenly into the crucible, heat up to 800°C at a rate of 20°C / min under the protection of 50L / h flow rate of nitrogen in a box furnace (Hefei Rixin High Temperature), heat preservation and activation for 1 hour, and then quickly cool to The activated material precursor was obtained at room temperature, the activated material was turned into a slurry, and the pH was adjusted to weak acidity...

Embodiment 2

[0085] Except changing the pre-oxidation temperature to 250° C., the same petroleum coke raw material as in Example 1 was pre-oxidized under the same pre-oxidation conditions as in Example 1 to obtain a pre-oxidation precursor. Mix the pre-oxidized precursor according to the mass ratio of NaOH: pre-oxidized precursor = 3:1 and put it into the crucible, and heat it up at a rate of 20 °C / min in a box furnace under the protection of nitrogen with a flow rate of 50 L / h After activation at 800°C for 1 hour, it was quickly cooled to room temperature under the protection of an inert atmosphere to obtain the precursor of the activated material. After the same purification and heat treatment as in Example 1, a petroleum coke activated carbon sample was obtained. Its specific surface area is 2187m 2 / g, mesopores with a pore diameter of 2-50nm account for 28% of all pores, the specific capacity of the organic system is 158F / g, and the specific capacity of the inorganic system is 270F / g....

Embodiment 3

[0087] In addition to controlling NaOH:preoxidation precursor=2:1 (mass ratio) during the activation process, the rest adopt the same conditions as in Example 1 to obtain petroleum coke-based activated carbon. Its specific surface area is 1823m 2 / g, mesopores with a diameter of 2-50nm account for 16% of the total pores, the specific capacity of the organic system is 152F / g, and the specific capacity of the inorganic system is 271F / g. Et at 1M 4 NBF 4 After 10,000 charge-discharge cycles in the / PC organic electrolyte, the capacity retention rate is 87%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific capacitance | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com